Scalloping – SINGER 319K User Manual

Page 89

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

87

SCALLOPED EDGES

£23824

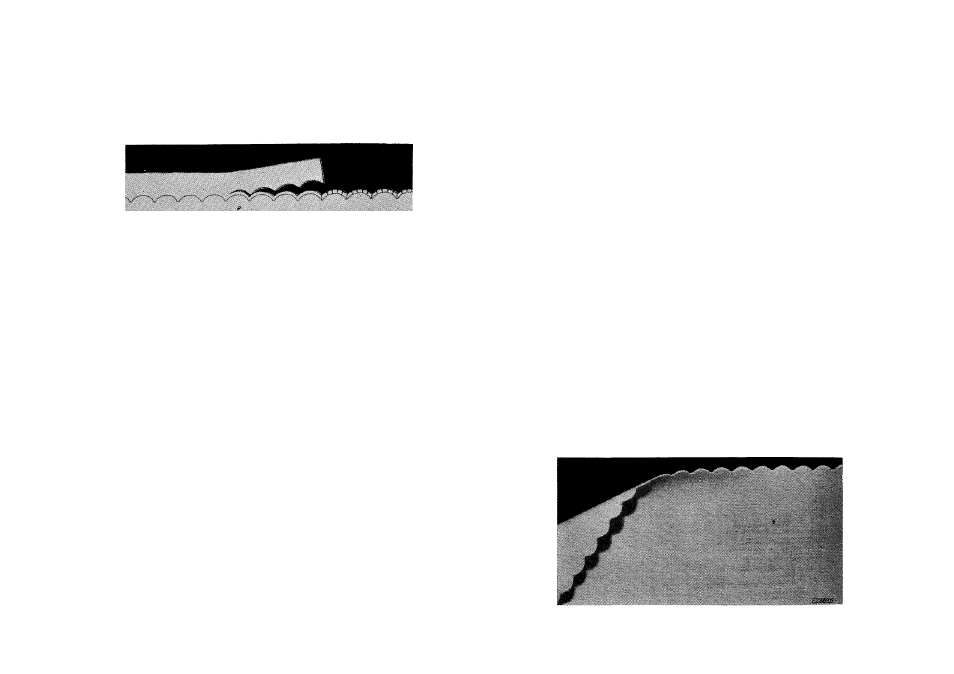

Fig. 167. Scalloped Edge in Process

Use: All-purpose Throat Plate and

All-purpose Presser Foot

Central Needle Position

5 Bight

12 to 25 Stitch, as desired

Lever C

SCALLOPING

When the Scallop Disc is in use, the needle moves to

form a scallop while the fabric moves in a straight line

under the presser foot. The depth of the scallop is con

trolled by the bight setting. A 5 bight produces a scallop

approximately deep and each bight setting of less

than 5 produces a correspondingly narrower scallop.

The length of scallop varies with the stitch length. A

12 stitch and a 5 bight produce a scallop approximately

IM" in length, a 25 stitch and 5 bight give approxi

mately a scallop, while a stitch length above 25

produces a scallop of in length or less depending

upon the stitch.

A single straight stitch separates each scallop providing

space for cutting when the seam edges are trimmed and

turned to form the finished, faced scallop edge.

Scalloped edges are used extensively on blouses, dresses

and on children’s wear.

Stitch in the same way as when making a straight seam.

The garment section will pass straight under the

presser foot while the needle follows a scallop pattern.

Trim seam allowance to less than 3^" and clip into each

point between scallops.

Blend this narrow seam by clipping small wedges at

regular intervals. When the scallop is turned, the

seamed scallop edge will have a smooth even contour.

Fig. 168. Scalloped Edge Completed