To reassemble and replace needle thread tension – SINGER 319K User Manual

Page 43

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

41

SHOULD IT BECOME NECESSARY TO REMOVE

AND DISASSEMBLE NEEDLE THREAD TENSION

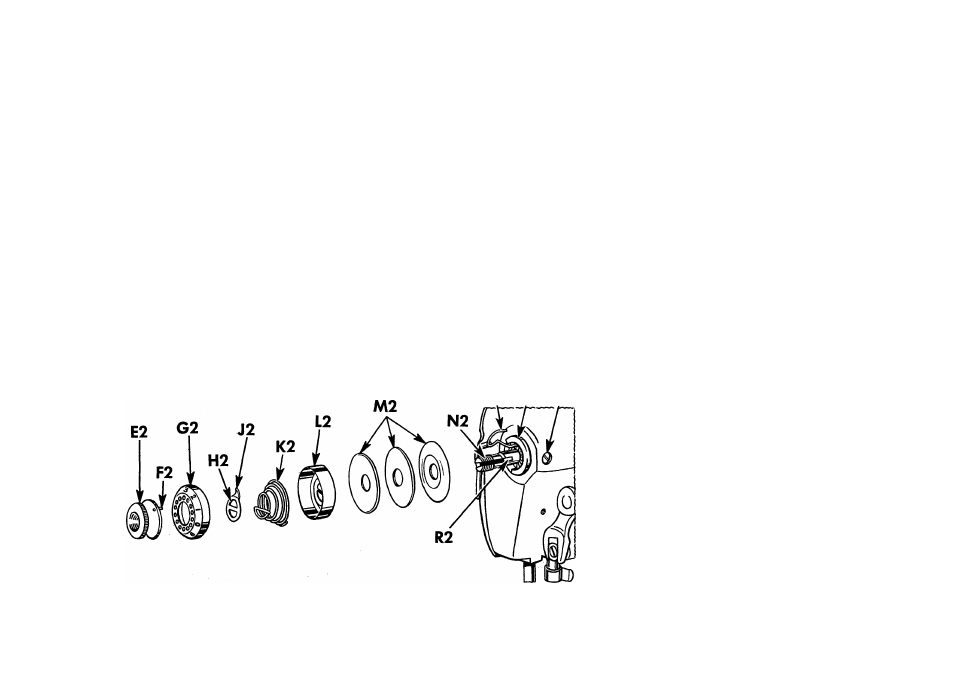

Turn thumb nut E2 to the left (counter-clockwise)

until "0” on dial G2 stops at center line on indicator

L2. To separate pin F2 in thumb nut E2 from dial

G2, press in dial, unscrew thumb nut and remove it.

Then remove tension parts from stud N2, as shown in

Fig. 69. Do not remove stud N2.

TO REASSEMBLE AND REPLACE NEEDLE THREAD TENSION

Make sure that tension releasing pin R2 is in place in

stud N2. Replace the tension parts on the stud N2 as

follows: Replace the three tension discs M2 with the

thick flat disc separating the convex surfaced discs.

Then replace the indicator L2, open side out, on stud

with plus and minus signs at top, then insert tension

spring K2 in indicator with the first (half) coil of this

spring straddling the lower half of the stud. Place stop

02 P2 Q2

washer on stud with extension J2 above stud, so that

it clears the first (half) coil of tension spring. Next,

place dial G2 on stud with No. 2 opposite stop washer

extension J2, then push dial to compress tension

spring and at the same time screw thumb nut E2 on

stud, inserting pin F2 on nut in one of the holes in

dial G2. Then lower presser bar and turn thumb nut

E2 to left until "0” on dial G2 stops at center line on

indicator L2. Thread the tension and

pull thread through tension discs to

test amount of tension on thread at

"0” position.

At this point there should be a slight

pull on the thread to indicate that

there is a minimum tension which

gradually increases with the turning

of thumb nut E2 to the right, pro

viding a full range of tensions with

one revolution of the thumb nut. If

the pull is too strong for a minimum

tension, press in dial G2 to disen

gage pin F2 on nut from dial, and

Fig. 69. Needle Thread Tension Assembly