Sears 113.29003 User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

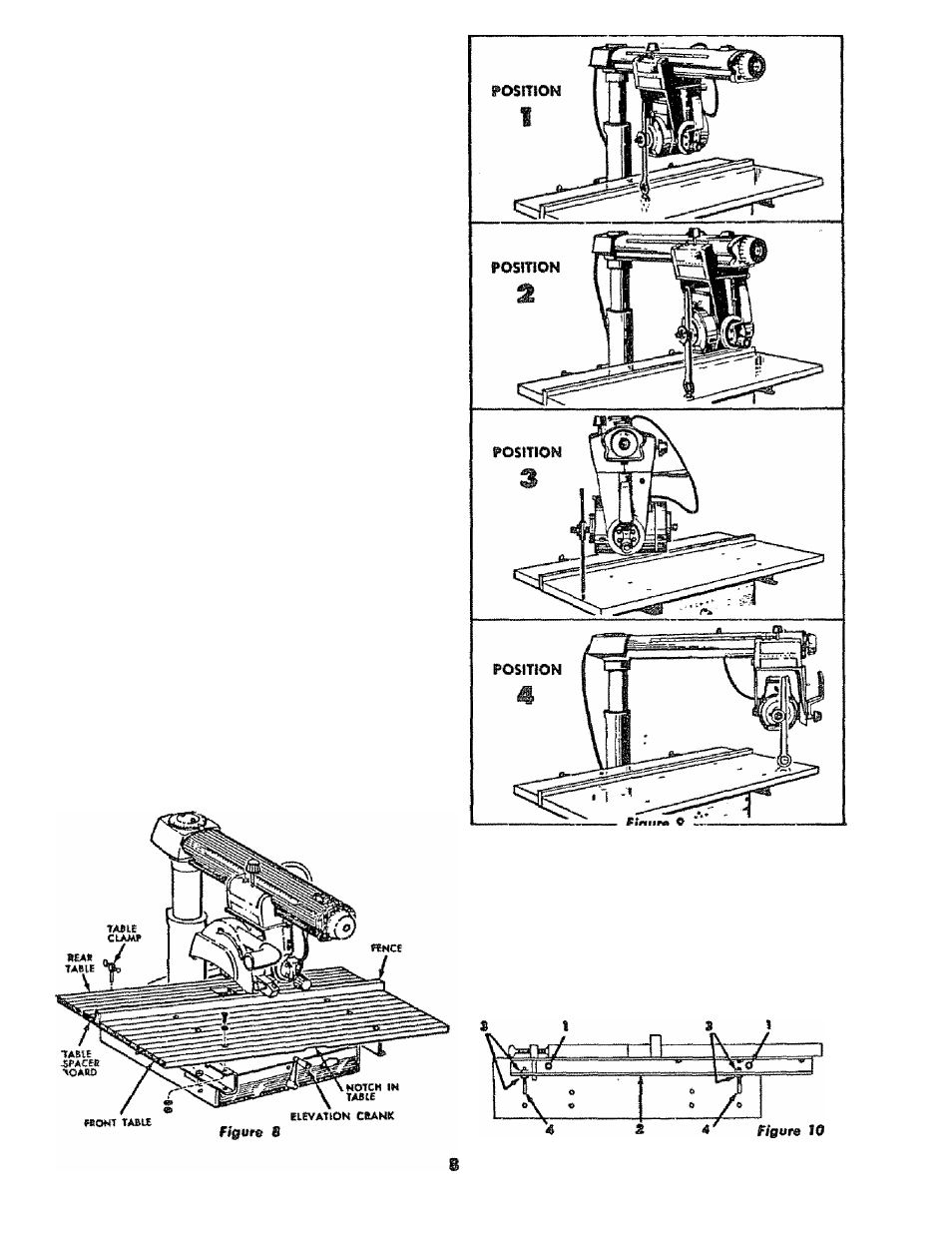

MOUNTING THE SAW TO A WORK 8ENCH

The saw should be placed on o suitable sturdy worfc bench

and positioned so that the elevation cranfc {figure 8) is free

to rotate. The base of the sow must be mounted to a fiat

oirfoce on the work bench to prevent distortion of the saw

ose. The nuts, strews, and washers which attach the wooden

shipping skids to the sow base may be used to »ecwè the

saw base to the work bench. Check that taw « level or

sloped slightly to the rear so that carriage when undamped,

does not run freely to the front end of the radial arm.

INSTALLATION OF THE TA8LE AND FENCE

1. Turn elevation crank to raise motor clear of shipping

brackets,

2. Remove shipping brockets from base.

3. Place front table on chonnels with notch In table for

ward and down as shown in Figure 8,

4. Align holes in front table with three forward mount

ing holes in chanriels. See Figure 8.

5. Assemble six mochine screws and washers through six

holes as drown,

6. Attach six lockwashers and nuts. Before tightening nuts

securely push table evenly toward reor of saw. Tighten

nuts.

7. lay fence in verticol position behind front table.

8. Lay table spocer board behind fence.

9. loy rear table with cut-out section forward behind table

spacer boord.

TO. Install table damps as shown and tighten securely

against edge of rear table.

ADJUSTING THE TABLE PARALLEL TO THE

RADIAL ARM

1. Remove sow guard with holding wosher and wing nut.

2. Remove sboft nut arid one loose collar on motor shoft.

See Figure 11.

. Insert arbor wrench between collars on motor draft. See

Figure 9. Tighten shoft nut by bond,

4. Tighten rodiol orm handle (Item Ì2, figure 5).

5.

Loosen carriage lock knob {item

7,

figure 5) and turn

elevation cronk until end of arbor wrench

just

touches

the table top thus permitting the wrench to be swung

bock and forth.

See Position 1, Figure 9. Mark this spot

0od Positions 2, 3 and 4 with

a

pencil,

note

Do not turn the elevotion crank throughout the re

mainder of this procedure as the radial arm must

remoin at the some height obove the table while

checking ot Positions 1, 2, 3 end 4 of Figure 9.

Figure

9

6.

Pull motor to Position 2. Wrench when moved bock and

forth should just contact table tap as in step 4.

7.

Tom arm latch handle (Item 12, figure 5} counterclock

wise and pull out. Move arm to Position 3 of Figure 9»

Tighten radial arm handle end repeat procedure of

step 6.

*

6. Move rodial arm to Position 4 of Figure 9, tighten radial

arm handle and repeot above procedure.

If contact between the wrench and the table tap Is not the

same of oil four positions the table con be leveled as fol

lows: (See Figure 10}.