Sesawing – Sears 113.29003 User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SESAWING

ReKJwin® is ibe cvtling ol thick boards into thinner ones. If

is о ripping operation. See Figure 29. Small boards—up to

2W"

maximum width—can be resawed in one pass; but

larger boards up to

5"

maximum require two passes,

one pass along each edge of the board. When two cuts

from opposite edges ore required, these should be made

to overlap

W’

from the approximate center of the board,

if the first cut is too deep, the kerf will close end bind the

sow on the second cut, with donger of kickback. Also, when

the kerf closes, the two sides of the cut ore no longer parallel

to the saw blade, and the saw will Cut Into them to spoil

their oppeorance. Keep the same face of the board against

the ferrce when making both cuts.

When cutting boords thicker than 4", a fence should be used

which extends

3W

above the table top. When cutting

boards thicker than 5", cut both sides ond finish the cut

with a bond sow.

BEVEL AND MITER CUTS

Bevel cuts can be mode from either a cross-cutting or ripping

position by tilling the blöde to the desired angle. Miter cuts

Can

be made only from о cross-cutting position when the

blode end radial arm are at some angle other than 90® to

the fence. A bevel miter cot is a cot which is both beveled

atid mitered. This cut Is mode with the blode cind rodiol orm

set at the desired miter angle to the fence and then the blode

only Is tilted with respect to the table top to the desired bevel

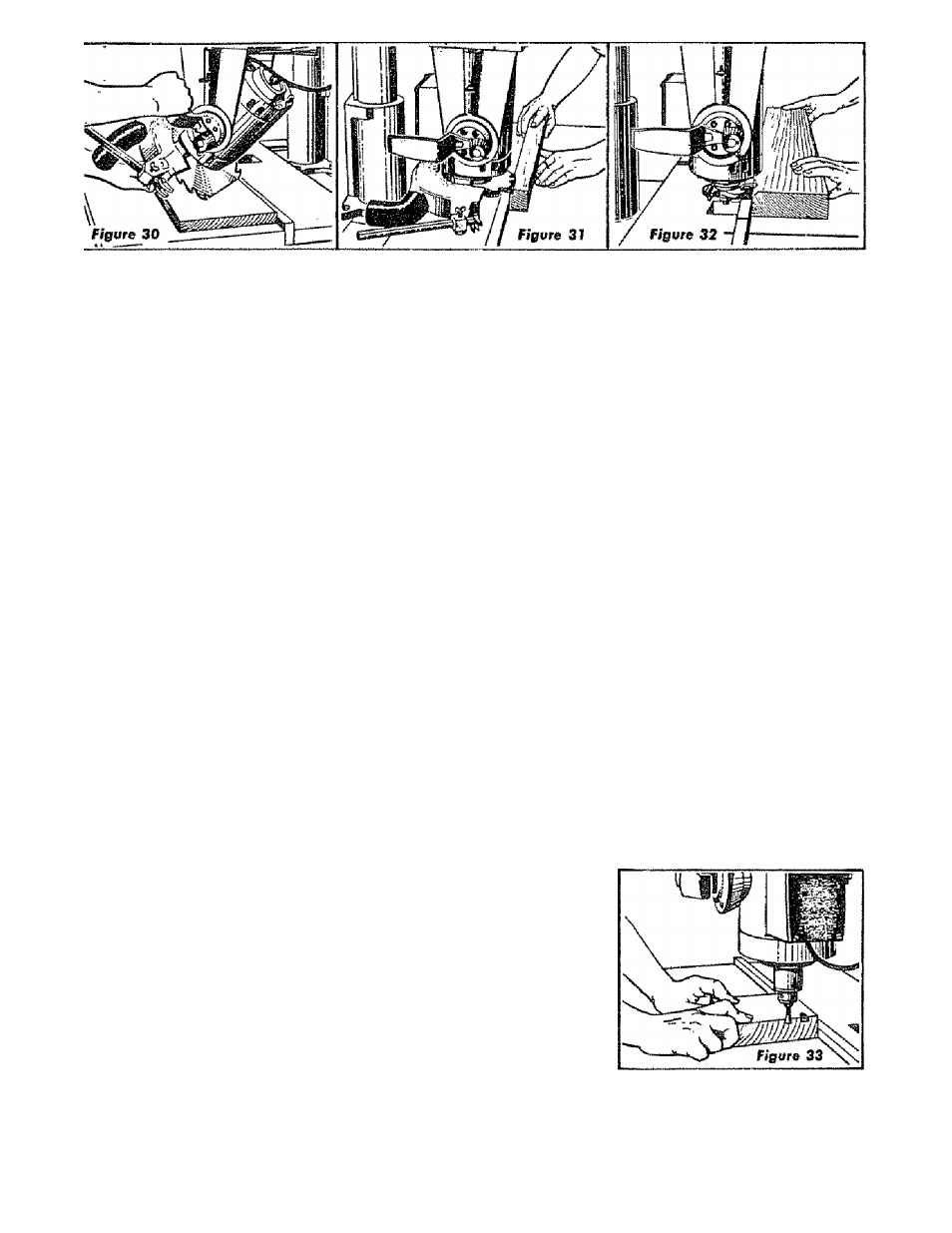

angle. This cut is also referred to as о compound miter. See

Figure 30.

USE OF THE DADO HEAD

The dado saw or head, as if is colled, is о special set of

blades for cutting grooves ond dados. Croftsmon 6” Krom-

edge Dodo Set can be purchased at any Sears Retail Store

or Mail Order House. The head consists of two outside blödes

1/8" Жкк, six 1/8“ thick chipper blades and paper wash

ers for 1 /16" width adjustments. With these blödes, grooves

of 1/8", 1/4", and odditional widths increosed in steps of

1/16" op to в maximum of 13/16" wide can be cut.

Outside

blades

con be used

atom, chippers cannot.

When using the maximum width of dodo of 13/16" on

the motor shoft, the outside loose coUor (Item 38, Figure 1)

must not be used. The width of the dodo con be reduced

while using the loose collar and two or more posses can be

mode with the work to obtain the desired width of cut.

Whenever two or more chippers are used, stagger the cut

ting ends os evenly os possible oround the circumference.

Fractiofsal odjustments in thickness of the heod con be mode

fay using poper washers between the outside blades ond

chippers. Dado head operotions are much the some os those

with

a

standard blade—but the dado head lakes о bigger

bite, so that the work-piece should be held more firmly.

When a groove wider than the dado head is needed, make

two or more passes. Space cuts so thot they overldp o trifle.

Dado work is done in the cross-cut position, Piougbing is

done in the ripping position. If the rip or plough position is

used die sow guard and anti-kickback pawl assembly should

be odjusted os described in the paragraph "RIPPING". Rab

beting is done in the vertical position. Figure 31. When

rabbeting, the motor is indexed 90° to the vertical position

to that the blodes are between the toble top ond the motor

and the yoke is indexed 90° clockwise and locked. The saw is

moved bock on the rodiol arm ond locked to the orm when

the omount of the blade extending forward of the fence it

equal to the depth of the robbei desired. If the depth of the

rabbet 1$ large, do not attempt to col it in one operoHon.

Lower the rodiol arm until the blades are in o position to cut

the desired width of rabbet in the edge of the board. The

bottom of the saw guard should be parallel to the fence and

the dischorge elbow directed to the rear of the saw.

MOLDING OR SHAPING

This work is done using the Croftsmon Molding Cutter Head

and

a

set of cutters depending on the type of molding cut

desired. This work is done with the saw in the some position

as that described for rabbeting. See Figure 32, Since the

position of the cutters with respect to the fence and the

table top can be adjusted any or all of the cutter shapes

can be used.

ROUTING AND DOVETAILING

Routing and dovetailing are done with the motor indexed

and locked 90° from the horlrontof except that this time

the externally threaded stub end opposite the norma! blade

end is between the motor and the table top. The follow

ing chucks will mate with this external 16-20 thread: (See

Figure 33).

0" to 1/4" Key Chuck

5/64" to 1/2" Key Chuck

The following routers and dovetails ore recommended:

1/8" router

1/4" router

3/8" rooter

1/2" router

5/8" rooter

3/8" dovetail

1/2" dovetail

Routing may be done by either moving the work with a

stationary rooter or by clomping the work to the table and

moving the router. Afwoys

approach the router bit from the

left hand side of the saw.

IS