Proper operating procedures, Lubrication, Standard saw operations – Sears 113.29003 User Manual

Page 13: Note

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

6.

foilghteti oil h«K head sa-avo and

holcktewn

screw. (Do noJ ollow occenirk bushing to rotate when

fightentng.)

7. Correct adjostroenf exisfs when there it no ploy between

the cafrioge and radial am), ond yet the carriage moves

freely. After adjustment is completed snugly %ht«n the

Iwo adjusting set Krews.

Caution: Do

not

avortightm.

8. Reploee corriage cover and lock knob assembly.

PROPER OPERATING PROCEDURES

DRESS PROPERIY — Operation of the sow is simple, safe

and easy—when properly done. Always be alert. Do not

wear a fie or other loose articles. Keep long sleeves down

with cuffs fastened or wear short sleeves, NEVER STOP

BEING CAREFUL One moment of inattention can cost you

a painful injury.

AVOID AWKWARD HAND POSITIONS —Do not get

hands info

a

position in which o sudden slip con couse them

to move into the sow blade. NEVER OPERATE THE SAW

WITH THE ARMS IN A CROSSED POSITION. Never hold

work on right side of blade with left hand while pulling sow

with the right hand. Do not ottempt free-hand cross-cutting.

Use o push stick when bond gets too close to the btode in o

ripping position.

- Twisting work will bind blade ond

NEVER TWIST WORK

cause

a

kickback.

Safety Pracaitihn

The motor is shipped with a shoft cap (Item 21,

figure 4) threaded onto the stub end of the motor

shaft. When this shoft end of the motor Is not being

used, this cop should olways be In place.

LUBRICATION

Your sow is

0 fine mochine and should be given the best of

core. If kept cleon ond properly lubricated, it will give шопу

yeors of trouble-free service. Before describing the various

points which may periodicolly require lubrication, ГГ IS

MORE IMPORTANT TO FIRST MENTION THE VARIOUS

SPOTS WHICH SHOULD NOT BE tUBRICATED.

NO LUBRICATION REQUIRED

Do not lubricate ony bolt races or any ball bearings.

Do not lubricate bearing fH of bevel Index handle (Hem 52,

figure 3) in yoke.

Do not lubricate the motor bearings. These ore sealed boll

bearings and require no added lubrication.

Do not lubricate bevel lortch pin (Item 31, figure 3) in yoke.

Do not lubricóte between radial arm cap fltem 12, figure 1)

and radial arm.

PERIODICALLY LUBRICATE THESE POINTS

Use SAE No. 10-30 Auto Engine Oil.

Apply o few drops of oil along the swive! latch pin (Item 6,

figure 3) only if the pin has o tendency to stick. Remove the

left-hand corrioge cover and use oil sparingly to prevent it

from getting on the ball bearings or races.

A light film of oil can be wiped on the lote of the column

tobe (Item 15, %ure 1) and keyway to lubricóte the fit

between this port and the key and column support (Items

21 and 19, figure

2).

Apply a few drops of oil to the bearing surfaces of the

olevotion crank shaft assembly (Item 29, figure 2), An oiling

hole is provided in the elevation shoft bearing brocket 0tem

23, figure 2) to facilitate the lubrication of the reor bearing

support.

The thread on the elevation shaft assembly (Item 30, figure

2}

con be lubricated through the oiling hols in the center

of the fodto! orm cop (Item 12, figure 1}.

STANDARD SAW OPERATIONS

CROSSXUniNG

Cross-cutting is the sawing of wood across the groin. Pionki

ore milted with the groin running the length of the plonk. If

a

straight cross-cut is desired, the board is placed on the

sow toble ogainst the fence so fhot the grain is parallel to

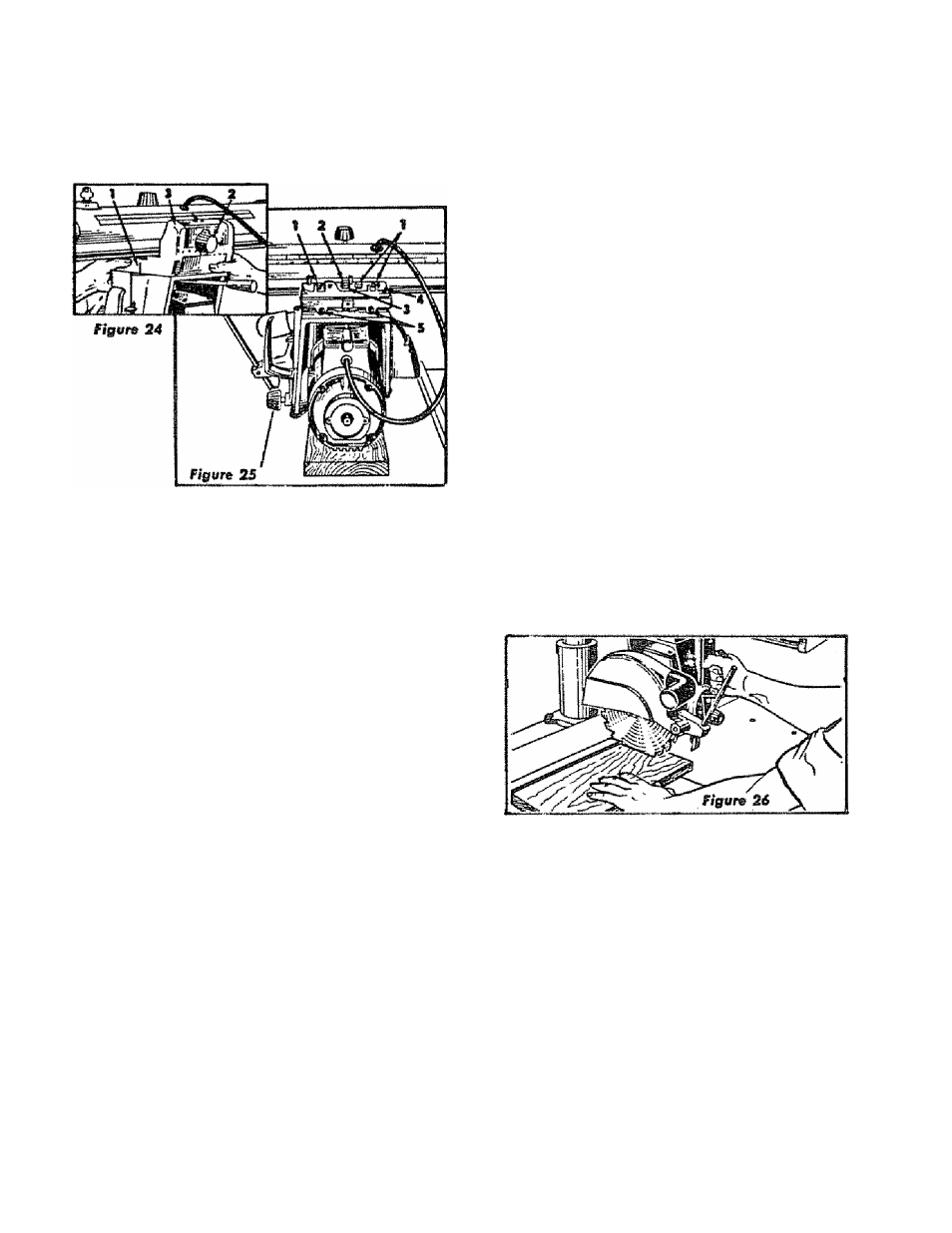

the fence, Figure 26.

NOTE

When cross-cutting normal pieces of lumber, the

long end of the board should be placed to the left

of Ae saw blade as the board is normally held by

the left hand during opereiian.

The radial arm must be positioned ot 0“ as indicated by the

radial arm position indicolor. The orm latch handle must be

indexed and tightened. See page 11 “Angular Movement

and Locking of the Radial Arm" for the most occurate setting

ert the 0* index position. The yoke must be indexed at the 0°

position, making the saw blade perpendicular to the rip

fence, and the yoke damp handle ploced in the locked posh

fion. The bevel index handle must be positioned at 0“, os

indicoted by the bevel scale, and locked. Turn the elevation

crank to lower the tow until the blade teeth are opproxi-

mafely 1/32" below the table surface in the sow slot

mode when performing the “PRELIMINARY CROSS-CUT

AT THE 0“ POSITION". Push the sow corrioge to the rear

of the rodio! arm so the blade is behind the rip fence. Adjust

the sow guard so the bottom is parallel to the table ond set

the onti-kickback paw! assembly so it Just dears the board

to be cut. Turn the switch key “On" to start the

taw

motor.

Hold the board firmly ogoinst the rip fence with the left hond

and grasp the bevel index handle with the right hand. The

cut is then made by pulling the corrioge forward until the

13