Caution – Sears 113.29003 User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Lay totnbinertion square or occurote sfeet square against

fence as shown in Figure 15 and position until it just

contacts

a

blade tooth (See A, figure 15). Mark this tooth.

When the carriage is moved back and forth on radial

arm saw tooth "A" should |ost touch square at oil positiorts.

If sow tooth "A" does not touch square os in step 3, adjust

os follows;

a. if sow tooth

"A"

(Figure 15) moves oway from the square

when moving the blade from the rear to the front of the

table, completely loosen the three screvrs holding the

table to the channel on the lefihond side of the table

end slightly loosen those on the right side of the table.

Slightly tighten the left table clomp (item 1, Position 4,

Figure 9).

b. tighten oil table screws first, then both table clomps.

Recheck blade squareness ogotrr.

c. Reverse this procedure if tooth "A" moves into the square

when moving the saw blade from the rear to the front

of the table.

In some coses, the above adjustment may not be sufficient.

If filis is the cose, adjust os follows:

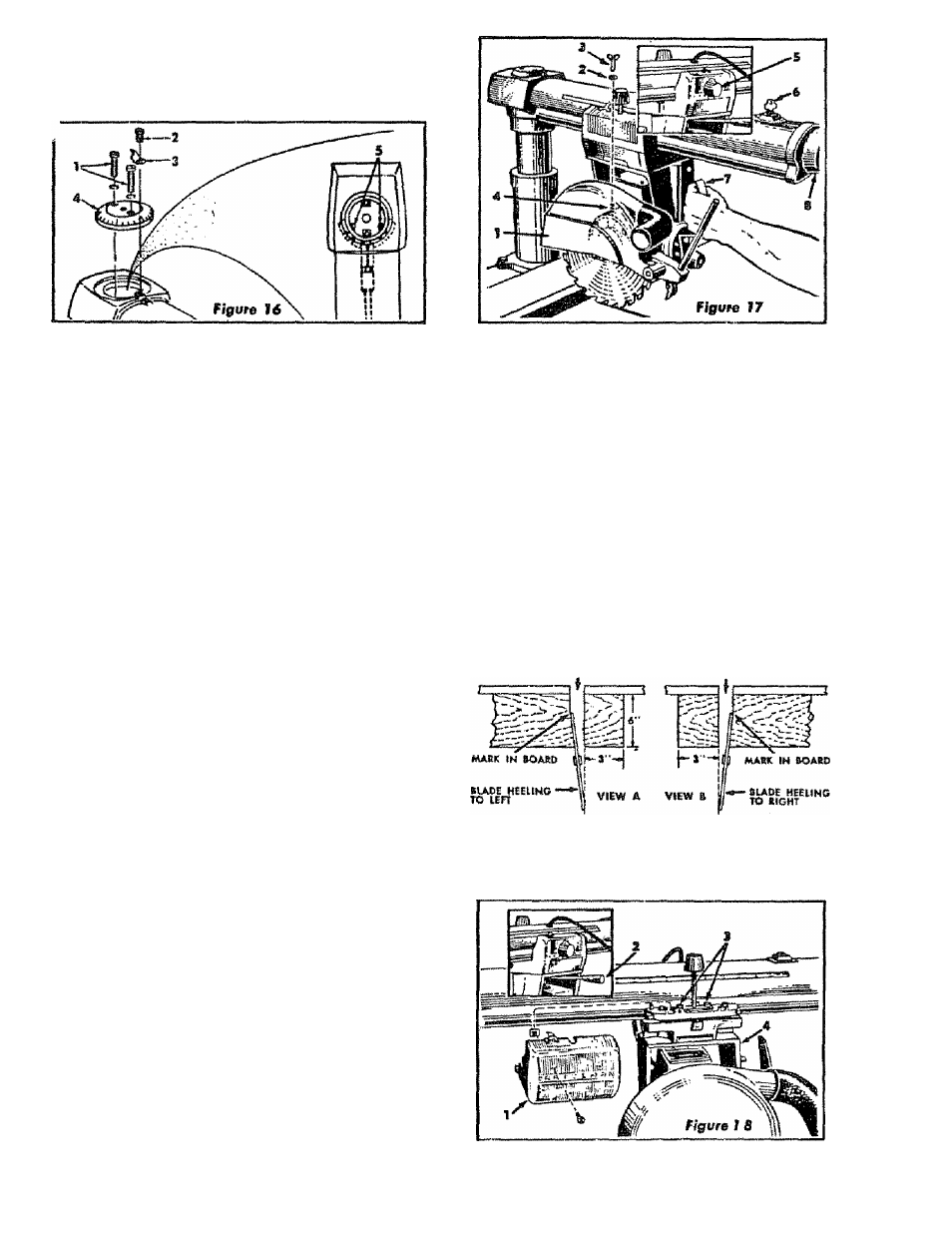

s. Remove three screws (item 1 and 2, figure 16), indicator

(Hem 3) and radial arm cap (Item 4).

b. Turn arm latch handle 1/2 torn counterclockwise to re

lease brake. Do not pull out.

c. Slightly loosen (do not remove) two hex head screws

(Item 5) inside of column tube.

d. Move radial arm in proper direction to moke saw tooth

“A" (Figure 15) follow edge of square when checking.

e. Retighten hex head screws (item 5, figure 16) and arm

iotch handle.

f. Recheck blade tooth *'A" travel with squore.

g. After blade is square to fence reassemble rodiol arm

cap and indicator using screws (Item 1 and 2, figure 16).

Set indicator at 0°.

PRfLIMINARY CROSS-CUT AT THE 0“ POSITION

1. Attoch saw guard (Item 1, figure 17) washer (Item 2} and

wing nut (Item 3) to motor and motor stud (Item 4),

2. Pull motor forward of fence so that blade is free to rotate.

3. lower radio! orm until saw blade just cleort table top.

4. Tighten carrtoge lock knob (item S, figure 17).

CAUTION

Before cutting always be sure fhot the arm Iotch

handle is locked fully clockwise. (Item 8, figure 17.)

5. Plug in power cord to receptaefe.

6. Insert switch key (Item 6, figure 17) and turn **On".

7. Lower radial arm until blade cuts into table top 1/32",

THIS IS ALL THAT IS NECESSARY-

To cut a blode clearance groove in the table ond fence hold

the bevel Index handle (Item 7, figure 17) with the (eft hand

and loosen the carriage lock knob (Item 5, figure 17) wHh

he right bond. Slowly pull the motor with the left hand out

to the extreme end of trove! and then push the motor back

through the fence to the extreme rear position. Turn fhe key

jwitch

"Off".

CHECKING THE SAW BLADE FOR HEEL

(LEFT AND RIGHT)

Using о scrap piece of one-inch lumber approximotely six

Inches wide, lay it on the table against the fence on the left

side of the blade. Position the board to permit a three-inch

piece to be cut from the right end holding the board firmly

against the fence with the left bond. Turn the key iwitefs

*‘On" ond commence the cut by pulling the sow forword

through the

board wnWf the

front half of the

saw

blade clears

m shown in

View A. Turn the switch "Off" and

allow the

saw blade to come to a complete stop while the rear

portion

of the blade is ttiil in contact with the wood.

Marks on the

foce of the board indkote left heeling. Check face of cut

board. See View A. To check for right heeling repeot the

same cirt from the right side of the blade. Check for heel

marb. See View B.

NOTE

The piece of wood must be held firmly agoinst the

fence and not permitted to move while the saw

blade is coming to о stop.

BUDE TBAVEt

BIADE TTiAVEL

Exaggerated

View of Heeling

Condition

To correct for heeling (left or right) proceed as follows:

1. Remove left hand carriage cover (Item 1, figure 16),

10