Operating controls – Sears 113.29003 User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

3.

2,' iooten yoke damp hondie (Item 2^ figure 18) by pulling

lhe_ handle horizontally toward the front of the low.

Sightly loosen the two hex heod machine screws {Item 3,

figure 18).

Rotate the yoke (Itero

4,

figure 18} very slightly opposite

to

the direction of heel, (For left heel, rotate yoke dock-

wise; for right heel rotate yoke counterdockwise.)

5. Retighten the two hex head machine screws (item 3,

figure 18) and roloek the yoke by pushing the yoke damp

handle toward the rear of the saw.

6. Recheck for left and right heel as before.

7. When the heeling condition is corrected the face of the

board will show no marb when cut from either side

of the blade.

8. Replace earrioge cover.

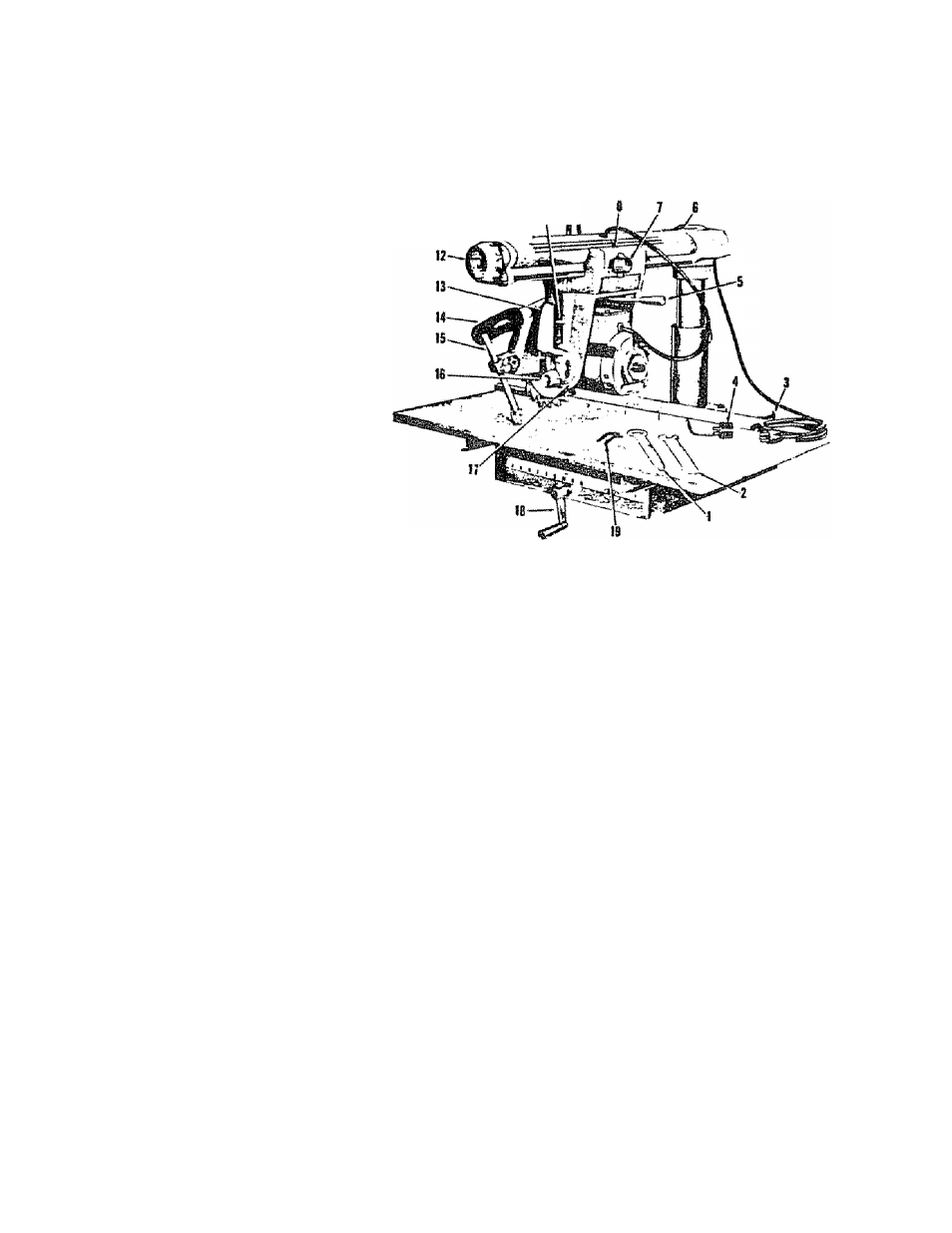

OPERATING CONTROLS

1. Arbor Wrench

2. Shaft Wrench

3. Table Ciomp

4.

Adapter Plug (foccept in Cortoda}

5. Yoke Clamp Handle

6.

Radial Arm indicator

7. Carriage Loch Knob

8. Rip Scale Indicator

9. Swivel Latch Pin ECnob

16. Latch Pin Handle

11. Switch Key

12. Arm latch Handle

13. Bevel Index Handle

14. Pischarge flbow

15. Anti Kidi Bach Pawl Assembly

16. Bevel Loch Knob

17. Bevel Index Scale and indicator

18. Elevation Crank

19. Hex “I" Wrenches

NOTE; WHEN ORDERING REPAIR PARTS

REFER TO PARTS LIST FOR COR

RECT PART NUMBER.

11 IE I

figure 19

RAISING AND LOWERING THE RADIAL ARM is ac

complished by the elevation crank (item 18, figure 19). One

complete

fum of this Hantih will raise

or fower.the

radial

arm W.

LOCKING THE CARRIAGE TO THE RADIAL ARM is

accomplished by the carriage lock knob (Item 7, figure 19).

Turn the knob clockwise to lock; counterclockwise to unlock.

ANGULAR MOVEMENT AND LOCKING OF THE RADIAL

ARM are controlled by the arm latch handle (Item 12,

figure 19). The radial arm can be rotated 360" and locked

in any position. The arm is unlocked from any position fay a

slight counterclockwise rotation of the arm lotch handle

ond is locked in any position by rotating the orm latch

handle clockwise until fight. The radiol orm hos positive

stops at 0® ond 45® left ond right, and is released from

these index positions by unlocking and pulling out the arm

latch handle (Item 12, figure 19). Due to positive arm

locking at the index positions, the arm latch handle

may be difficult to pull out. A few turns to the left will

releosa it.

For most positive ond accurate settings at the index posi

tions, the following is recommended;

1. If the radiol arm is olready indexed, unlock and poll

out the arm lotch hondle and move the rodial arm off

of the Index position. Release the arm latch handle.

2. Before moving the radial orm to the desired index posi

tion, turn the arm latch handle (Item 12, figure 19) just

1/4 turn counterclockwise from the locked position,

3. Move the rodio! arm into the index position (do not

bump or jar) and hit the face of the arm latch hondle

solidly with the palm of the hand.

4. lock the rodial arm by turning the arm latch handle fully

clockwise.

CAUTION; When moving the radial arm in any

direction beyond 45® left or right, always pull out

the arm latch handle (at end of radial arm) to

prevent damaging the arm lock pin. If damage

occurs, the radial arm will not index properly at

0" ond 45" left or right.

MOVEMENT AND POSITION OF THE MOTOR IN THE

YOKE ar^ controlled by the latch pin hondle (Item 10, figure

19) end bevel lock knob (Item 16, figure 19). The bevel scole

indicates the ongufor position of the motor with respect to

the horizontal from 0® to 90® in either vertical position. The

latch pin handle aufomolicalty indexes the motor at 0°, 45°,

and 90° up and down. Lift to releose. At any other posi

tion the latch pin handle is not engaged. The bevel lock knob

iocb the motor to the yoke when the motor is in any posi

tion, Locking is clockwise; unlocking is counterclockwise.

MOVEMENT AND POSITION OF THE YOKE are con

trolled by the swivel fotch pin knob (Item

9,

figure 19) and

the yoke clomp hondie (Item 5, figure 19}. The swivel lotch

pin aufomotkally indexes the yoke at each 90° position and

two 45° positions, lift to releose. The yoke clamp hondie

Iocb the yoke to the carriage in any position. Pull to release.

Push to tighten. When ’Tn Ripping" it moy be desirable to

hove more free table in front of the sow falode than is ob

tainable when the radiol arm is at the 0° posiflon. With

the blade in th normal cross-cut position index the rodio!

arm to 45° left ond lock It. Then loosen the yoke clomp

hondle and index the yoke 45“ clockwise, Reclamp the

yoke clomp hondle. The added free table space is now to

the right of the blade and ripping should be done from the

right side of the table. The reverse is also true for "Out

Ripping" by indexing the rodial arm 45“ right ond index

ing the yoke 45° counterclockwise. The added table space

is now to the left of the blade ond ripping should be done

from the left side of the table.

CAUTION: Under these two conditions the In-Rip

and Out-Rlp scales connot be used.

n