Oc: qvantst, inn «»s'«* bv – Carrier 38VH User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

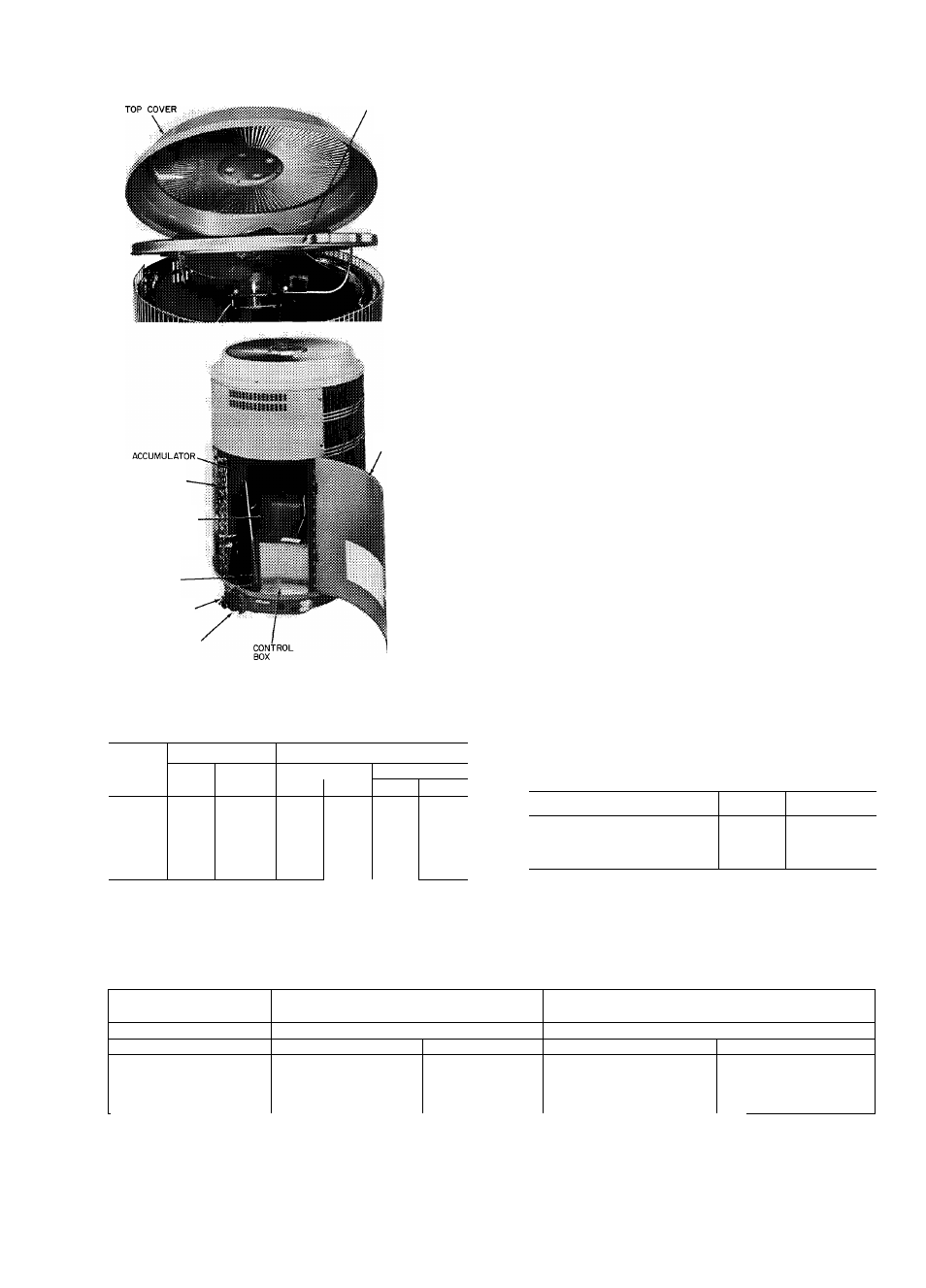

FAN MOTOR

ORIFICE PLATE

ASSEMBLY

HATCHBACK

ACCESS DOOR

CONDENSER

COIL

COMPRESSOR

(INSIDE SOUND

SHIELD)

HIGH-LOW-

PRESSURE

SWITCHES

LIQUID VALVE

SERVICE PORT

SUCTION VALVE

SERVICE PORT

Fig. 6 — Condensing Unit 38VH

with Access Door Open

Table 6 — Service Data

UNIT ;

38VHt

R-22 CHG‘

CONDENSER FAN

Lbst

Lbs-Ozf

Low Speed

hligh Speed

Rpm

Cfm

Rpm

Cfm

001

5 5

5-8

650

2300

800

2800

002

103

10-5

750

2300

900

2800

003

9 1

9-2

750

2300

900

2800

004

9 2

9-3

750

2650

900

3200

045

9 2

9-3

750

2650

900

3200

005

8.1

8-2

850

3150

1050

3900

‘Factory refrigerant charge is adequate when evaporator and con

densing unit are same size, and are connected with 25 ft or less of

field-supplied tubing of recommended size or 50 ft or less of

Carrier accessory tubing

fNot to be used for 28VH applications See "Weight Method —

28VH Applications "

On systems having field piping in excess of 50 ft,

add refrigerant and oil as shown in Table 9.

Service port connections are provided on liquid

and suction line service valves for evacuation and

charging. See Fig. 6.

TO CHECK, ADJUST OR REPLACE REFRIG

ERANT CHARGE use method recommended in

Table 7. Details of charging methods are listed

below.

Before recharging system, thoroughly evacuate

system and then weigh in refrigerant charge speci

fied in Table 6. Check or adjust charge as required.

Refer to Carrier Standard Service Techniques

Manual, Chapter 1, Refrigerants, for additional

system evacuation and dehydration instructions.

WEIGHT METHOD — Refer to Table 6 or unit

nameplate for correct system refrigerant charge. Re

move any refrigerant remaining in system before

recharging.

When system is not evacuated, subtract the

following amount from total charge.

38VH001,002

—.10 lb (1.6 oz)

38VH003,004,045,005

—.20 lb (3.2 oz)

The Dial-a-charge charging cylinder is an accu

rate device used to recharge systems by weight.

These cylinders are available at refrigerant supply

firms.

28VH Applications

— Use of the 38VH002,003

and 004 units with matching 28VH indoor coils, for

high SEER (Seasonal Energy Efficiency Ratio) per

formance, requires the weight method of charging.

Discharge the factory charge into a proper container

and weigh in the correct charge as shown below. The

charge is critical for proper operation and the weight

method is the recommended charging procedure.

Charging Weights — 28VH Combinations

(Refrigerant R-22)’

SYSTEM COMBINATIONS

LBS

LBS-OZ

38VH002/28VH002

9 1

9-2

38VH003/28VH004

9 1

9-2

38VH004/28VH004

9 3

9-5

‘These charges are for 25-ft of tubing See Refrigerant Charging,

page 6, for charge variation of other than 25 feet

Table 7 — Refrigerant Charging Methods

CONO UNIT

METHODS OF CHECKING OR

ADJUSTING CHARGE

METHODS FOR COMPLETE

RECHARGING

38VHt

System Refrigerant Control

System Refrigerant Control

Non TXV

TXV

Non TXV

TXV

001,002

003.004

045.005

Chargemaster

or

Charging Chart

Sight

Glass*

Weight Method

plus

Chargemaster or

Charging Chart

Weight Method

plus

Sight Glass‘

‘Sight glass field supplied and installed in liquid refrigerant line

fNot to be used for 28VH applications See "Weight Method — 28VFI Applications "

«oc:

qvantst, inn «»S'«* bv

TftiS

ivjiA

lAfiJfntSnti i/t