Table 3 — field-supplied tubing data, Step 2 — make tubing connections, Fig. 3 — refrigerant line hangers – Carrier 38VH User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Condensing Units Connected to Non-Carrier Evap

orators — Check refrigerant charge when the con

densing unit is added to a system in which other than

a Carrier-approved evaporator is to be used or

where the evaporator has been previously installed.

Check that field-supplied refrigerant piping is in

accordance with refrigerant piping data (Table 3).

Step 2 — Make Tubing Connections

— Con

densing units may be connected to evaporator sec

tions using Carrier accessory tubing package or

field-supplied tubing of refrigerant grade. See Table

4 for accessory tubing sizes. Table 3 for recom

mended field-supplied tubing sizes.

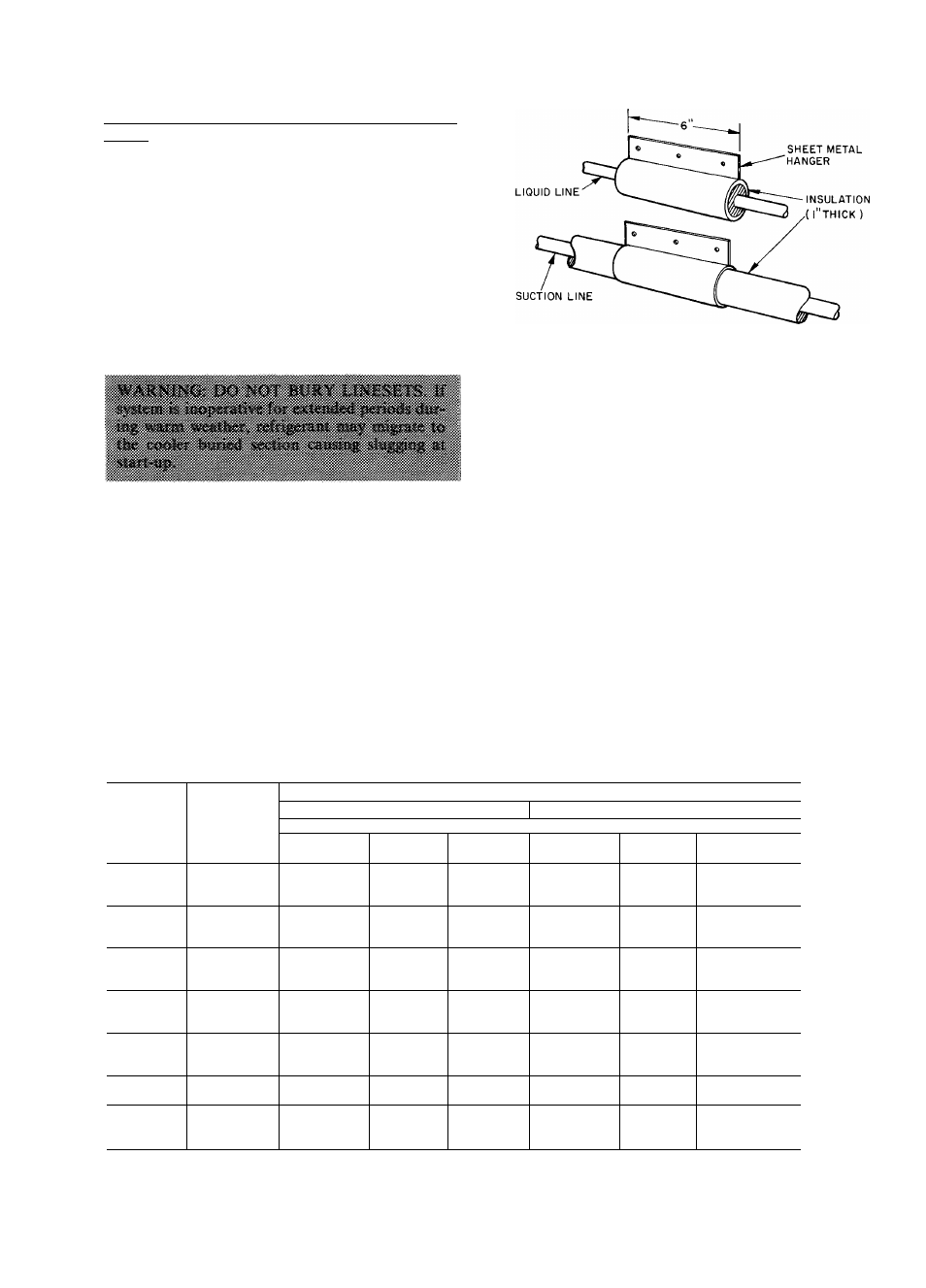

Isolate interconnecting tubing from framing and

ductwork or where tubing runs thru stud spaces,

enclosed ceilings or pipe chases. Use isolation type

hanger (Fig. 3) since rigid fastening transmits pulsa

tions to structure creating objectionable sound.

A capacity and efficiency reduction results if

undersized Carrier accessory tubing is used in 38VH

systems. (Example: When a 25-ft accessory tubing

Fig. 3 — Refrigerant Line Hangers

package is used on a 38VH004 system, the smaller

suction line will result in a capacity reduction of 3%.)

For maximum capacity and efficiency from this sys

tem, use suction line recommended in Table 3.

Length of interconnecting tubing may necessitate

refrigerant charge adjustment. Follow special re

quirements described in Initial Start-Up, Refrig

erant Charging. Do not use less than 10 ft of inter

connecting tubing. On Carrier accessory tubing

packages, do not cut 5/16-in. or 1 / 4-in. liquid line or

7/8-in. suction line. These tubing packages have

swaged ends. If swage at end of tubing is cut off, the

tubing will not fit into unit refrigerant line fittings.

Bend or coil excess tubing to fit.

Table 3 — Field-Supplied Tubing Data

NOTES

1 Maximum allowable vertical separation for evaporator over the

condensing unit is 50 feet

2 Over 50-ft vertical separation, the condensing unit must be

located above evaporator

3 The maximum total tubing length between units is 150 feet

4 All suction tubing must be insulated with 3/8-in thick, flexible

foam tubing (Armaflex 22 or equivalent)

5 Piston numbers effective December 1, 1979

Vertical separation from 51 to 100 feet (Condensing unit

iabove evaporator)

CONO

UNIT

38VH

EVAP

SIZE

REFRIGERANT LINE LENGTH (ft)

10 to 50 ft

51 to 150 ft

Line Diameter

Suction

(in.)

Liquid

(in.)

Indoor

Piston*

Suction

(in.)

Liquid

(in.)

Indoor

Piston*

018

5/8

3/8

52

3/4

5/16

52 ^

001

024

5/8

3/8

52

3/4

5/16

52 ■

030

5/8

3/8

TXV

3/4

5/16

TXV ■

024

7/8

3/8

57

7/8

5/16

57 ■

002

030

7/8

3/8

59

7/8

5/16

59 ■

036

7/8

3/8

TXV

7/8

5/16

TXV ■

030

7/8

3/8

63

1-1/8

5/16

63 ■

003

036

7/8

3/8

65

1-1/8

5/16

65 ■

042

7/8

3/8

TXV

1-1/8

5/16

TXV ■

036

1-1/8

3/8

76

1-1/8

5/16

76 U.

004

042

1-1/8

3/8

78

1-1/8

5/16

78 ■

048

1-1/8

3/8

TXV

1-1/8

5/16

TXV ■

042

1-1/8

3/8

76

1-1/8

3/8

76 ■

045

048

1-1/8

3/8

78

1-1/8

3/8

78 m.

060

1-1/8

3/8

TXV

1-1/8

3/8

TXV »

nriR

048

1-1/8

3/8

82

1-1/8

3/8

82 ■

060

1-1/8

3/8

84

1-1/8

3/8

84 fm

002

28VH002

1-1/8

3/8

63

1-1/8

5/16

63 W

003

28VH004

1-1/8

3/8

70

1-1/8

5/16

70 W

004

28VH004

1-1/8

3/8

78

1-1/8

5/16

78 B

*At 95 F outdoor air design temperature At other design temperatures, piston sizes may vary See Table 2