Carrier 38VH User Manual

Air-cooled condensing units

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Number One

AirCorditbninq

Maker

Division of

Carrier Corporation

Carrier Parkway • Syracus

N Y 13221

Air-Cooled Condensing Units

INDEX

Page

SAFETY CONSIDERATIONS........................... 1

INSTALLATION

Step 1 — Check Equipment and Jobsite.... 2,3

• UNPACKAGE UNIT

• INSPECT EQUIPMENT

• COMPLETE OR CONSIDER SYSTEM

REQUIREMENTS

Step 2 — Make Tubing Connections ............... 3-5

• REPLACE THE ACCURATER™

REFRIGERANT CONTRQL PISTON IN

THE INDOOR COIL

• CONNECT REFRIGERANT LINES

Step 3 — Make Electrical Connections........... 5,6

• INSTALL A BRANCH CIRCUIT

DISCONNECT PER N.E.C.

• ROUTE LINE POWER LEADS INTO UNIT

• CONNECT GROUND LEAD AND

POWER WIRING

• CONNECT CONTROL POWER

WIRING (24 v)

START-UP................................................................ 6

SERVICE.................................................................. 9-II

MAINTENANCE.................................................. I I - I 2

SAFETY CONSIDERATIONS

Installation and servicing of air conditioning

equipment can be hazardous due to system pres

sure and electrical components. Only trained

and qualified service personnel should install,

repair or service air conditioning equipment.

Untrained personnel can perform basic main

tenance functions of cleaning coils and cleaning

and replacing filters. All other operations should bci

performed by trained service personnel. When

working on air conditioning equipment, observe

precautions in the literature, tags and labels

attached to the unit and other safety precautions

that may apply.

Follow all safety codes. Wear safety glasses and

work gloves. Use quenching cloth for brazing

operations. Have fire extinguisher available for all

brazing operations.

WARNING; Before performing service or

maioienance oj^erairon^ on system, turn off

m^n power switch to iadoor mut and

out

door

UJI&. Tui» off accessory heater power

switch

if

applicable.

Eleetrical

shock

could

cause

persoii^

injury.

ik

-If MTG

SLOTS(USE ANY

2)

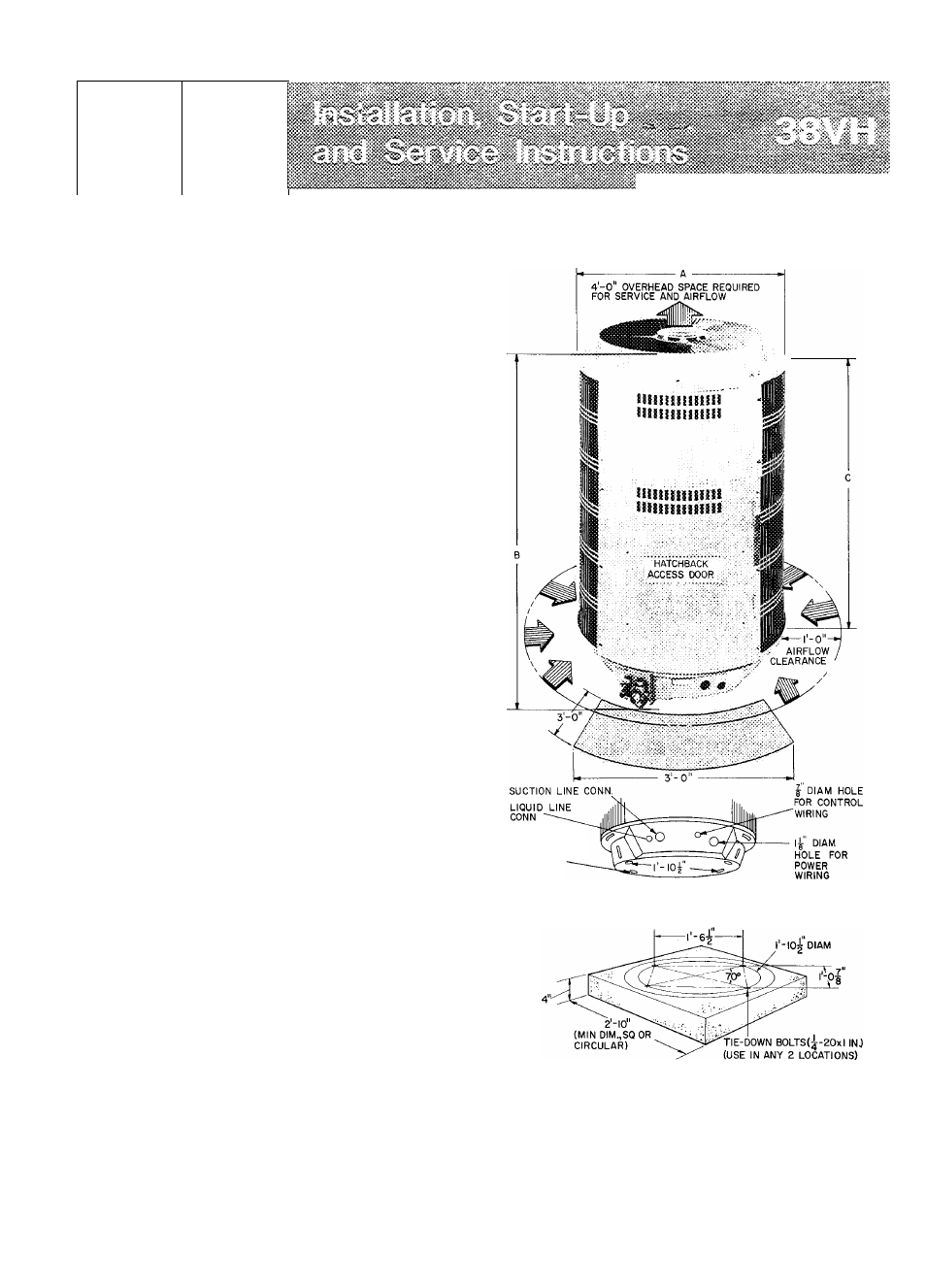

C=3 SPACE REQUIRED FOR SERVICE

^ CONDENSER AIRFLOW

CONCRETE MOUNTING PAD^ISQUARE OR CIRCULAR)

^CONCRETE PAD SHOULD WEIGH |-f TO 2 TIMES WEIGHT OF UNIT

Certified dimension drawings available on request

Fig. 1 — Dimensions, Connections and

Mounting Pad

© Carrier Corporation 1980

Form 38VH-2SI

Document Outline

- Air-Cooled Condensing Units

- INSTALLATION

- Table 3 — Field-Supplied Tubing Data

- START-UP

- CAHTIONt To

- Do not overcharge sysicio. Aa overcharge

- Table 8 — Chargemaster Charging Chart (Non TXV Systems)t

- SERVICE

- Unit Controls and Safety Devices

- Compatible Fitting Repair

- Condenser Fan Motor Removal

- MAINTENANCE

- Lubrication

- TROUBLESHOOTING GUIDE

- SYMPTOM AND PROBABLE CAUSE

- COMPRESSOR SHUTS OFF, FAN OVERLOAD

- OR HIGH PRESSURE SWITCH CUT OUT, OR

- INTERNAL PRESSURE RELIEF OPENS

- COMPRESSOR RUNS BUT COOLING IS INSUFFICIENT

- High Suction Pressure

- PROBABLE REMEDY

- COMPRESSOR SHUTS OFF FROM LOW-PRESSURE SWITCH CUTOUT

- Evaporator Fan Stopped

- COMPRESSOR SHUTS OFF,

- WILL NOT RESTART

- Contactor Closed or Closes Then Opens