Carrier 38VH User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 5 — Electrical Data

COND

UNIT

38VH

V/PH

OPER

VOLTS*

COMPR

FAN

BRANCH CIRCUIT

Min Wire

Sizet

(AWG)

Max Ft

Wiref

Min Gnd

Wire

Size

Fuse

Ampsj;

Max

Min

LRA

RLA

FLA

001

40 6

6 9

9

14

37

sa

12

15

002

49 0

103

9

14

12

26

41

12

25

003

208-230/1

253

197

69.0

154

9

12

28

44

10

35

004

83 5

17 9

1 2

10

a

38

S9

8

40

045

88.0

17.1

1.2

10

s

39

a?

8

35

005

230/1

253

207

97 0

22 4

2 3

10

8

32

-

*

8

50

f

Corresponding wire sizes and wire lengths

FLA — Full Load Amps

LRA — Locked Rotor Amps

RLA — Rated Load Amps

’Permissible limits of the voltage range at which the unit will operate

satisfactorily

tCopper wire sizes and lengths

ifMaximum dual element size

NOTE Control circuit is 24-v on all units and requires externa I power source

Mechanical Connection — (Mate one set of con

nections at a time.)

1. Loosen nut on Compatible Fitting one turn.

Do not remove.

2. Remove plug and be sure O-ring is in the

groove inside the Compatible Fitting.

3. Cut tubing to correct length, deburr and size

as necessary.

4. Insert tube into Compatible Fitting until it

“bottoms.” Tighten nut until it bottoms on

back coupling flange. Keep tube bottomed in

Compatible Fitting while tightening nut.

Sweat Connection — (Use refrigerant grade tubing.)

1.

Remove locking nut, rubber O-ring and

Schraeder core and cap from valve service port.

2. Cut tubing to correct length, deburr and size

as necessary.

3.

Insert tube in Compatible Fitting until it

“bottoms.” Wrap top and bottom of service

valves in wet cloth to prevent damage by heat.

Solder with low-temperature (450 F) silver

alloy solder.

4. Replace Schraeder core and cap.

5. Evacuate or purge system using field-supplied

refrigerant.

Step 3 — Make Electrical Connections

— Be

sure field wiring complies with local and national

fire, safety and electrical codes, and that voltage

to unit is within limits shown in Table 5. Contact

local power company, for correction of improper

line voltage.

See Table 5 for recommended wire and fuse sizes.

When making electric connections, provide clear

ance at unit for refrigerant piping connections.

INSTALL A BRANCH CIRCUIT DISCONNECT

PER N.E.C. of adequate size to handle unit starting

current. Locate disconnect within sight of and

readily accessible to the unit, per section 440-14 of

National Electrical Code (NEC).

ROUTE LINE POWER LEADS INTO UNIT —

Extend leads from disconnect thru hole provided

in basepan (Fig. 1) and into unit junction box.

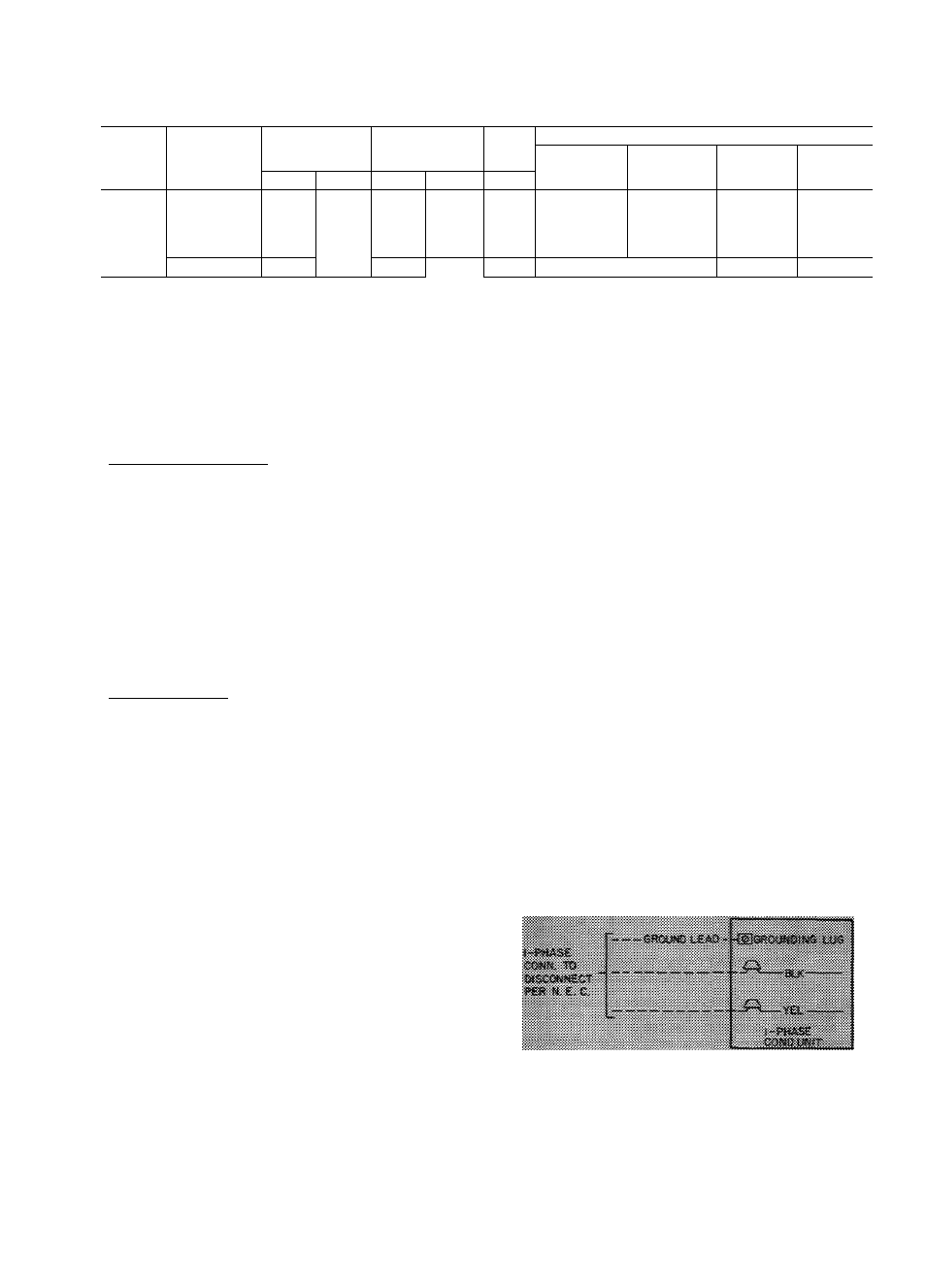

CONNECT GROUND LEAD AND POWER

WIRING — Connect ground lead to a ground lug in

control box for safety. Then connect power

wiring. See Fig. 4. Splice line power leads to yellow

and black pigtails. Use wire nuts and tape at each

connection.

Opersíío» of isail on improper Uise voltage

coasnstutes al>ííse and coaid aHect

C&tei&i:

Wsrranty. See Table 5, Do noi apply unit

m

sysiens wliem voltage may fluctiiate above or

Splice Connections

______Field Wiring

______ Factory Wiring

Fig. 4 — Line Power Connections