Unit controls and safety devices, Compatible fitting repair – Carrier 38VH User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

12. Triple-evacuate system. Recharge system as

described previously.

Filter-Drier

— Install field-supplied filter-drier

(Table 4) in system liquid line when refrigerant

system is opened for service as described under

Compressor Removal. Position drier in liquid line

at convenient location.

Pumpdown Procedure

— The system may be

pumped down in order to make repairs on low side

without losing complete refrigerant charge.

1. Attach pressure gage to suction service valve

gage port.

2. Frontseat the liquid line valve.

3. Start unit and run until suction pressure reaches

5 psig (see Caution).

4. Shut unit off and frontseat suction valve.

5. Vent remaining pressure to atmosphere.

Unit Controls and Safety Devices

HIGH-PRESSURE

RELIEF

VALVE,

when

equipped, is located in compressor. Relief valve

opens if system operating pressure differential

between suction and discharge pressure reaches

500 psi on all models.

HIGH-PRESSURE SWITCH is located on unit

liquid line. High-pressure switch settings are: cut

out, 425 ± 5 psig; cut-in, 320 ± 20 psig.

LOW-PRESSURE SWITCH is located on unit suc

tion line. Low-pressure switch settings are: cutout,

31 ± 4 psig; cut-in, 60 (+15, -0) psig.

INTERNAL TEMPERATURE AND/OR CUR

RENT SENSITIVE OVERLOADS reset auto

matically when motor internal temperatures drop

to a safe level (overload may require up to 30 min

utes to reset). When internal overload is suspected

of being open, check by using an ohmmeter or

continuity tester. If necessary, refer to Carrier

Standard Service Techniques Manual, Chapter 2,

Electrical, for complete instructions.

INHERENT FAN MOTOR PROTECTION —

Protects

motor

from

abnormal

current

and

temperature.

SOLID STATE TIME GUARD® CIRCUIT pro

tects unit compressor by preventing short cycling.

Time Guard provides a 5 ± 2-minute delay before

restarting compressor after shutdown for any

reason. On normal start-up, the 5-minute delay

occurs before thermostat closes. After thermostat

closes, the Time Guard then provides a 3-second

delay to prevent contactor chattering.

CRANKCASE

HEATER

SWITCH

^

The

purpose of the heater is to keep the crankcase

warm during the off cycle and thus prevent dilution

of the oil with refrigerant. This assures good lubri

cation and prevents loss of oil from erankcase

during start-up. Switch closes (activates) at 65 F on

coil temperature drop. Opens (deactivates) at 85 F

on coil temperature rise.

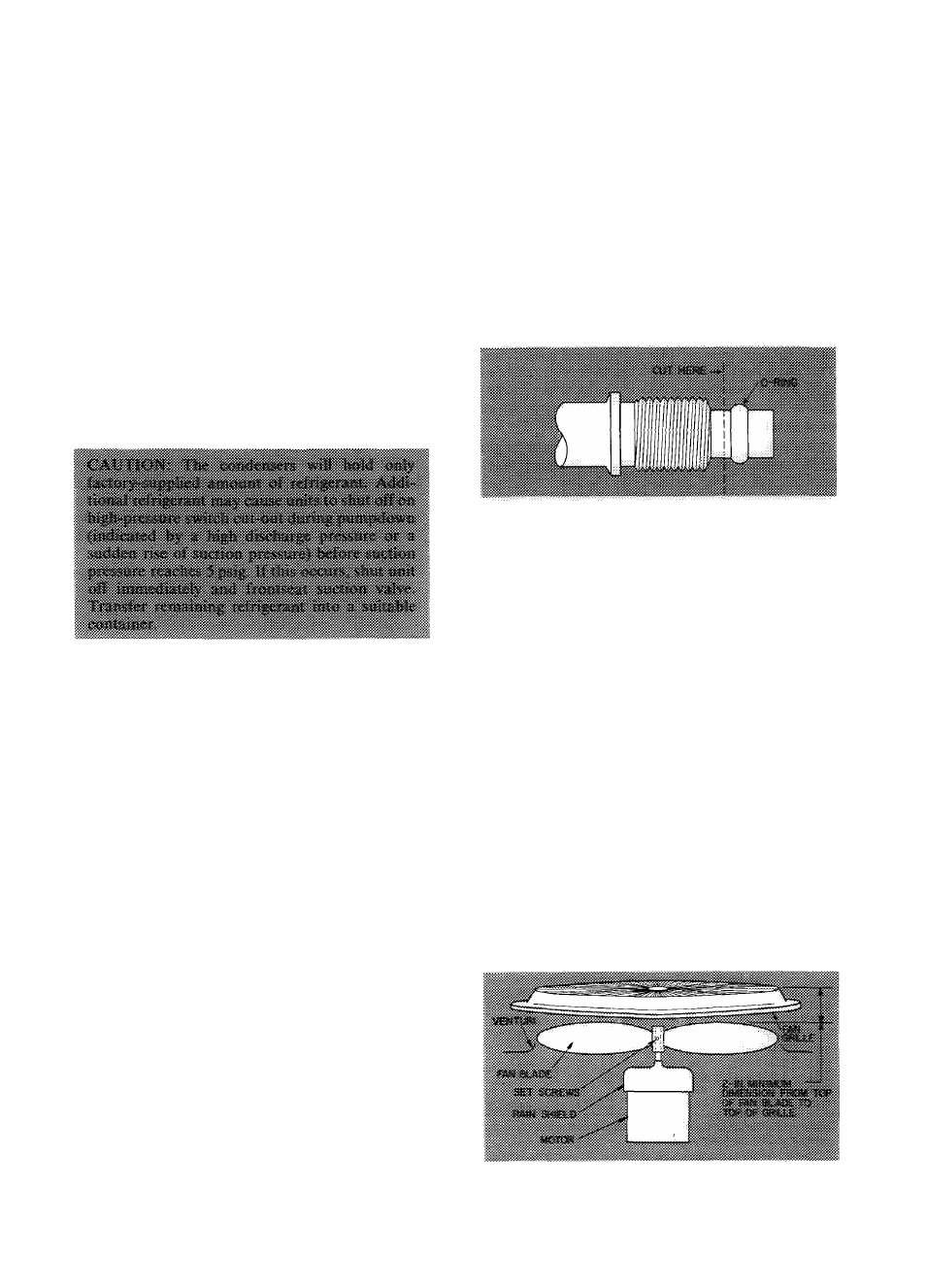

Fig.

Repair of Mechanical Connection

Compatible Fitting Repair

MECHANICAL CONNECTION — Frontseat unit

service valves. Relieve refrigerant pressure from

tubing. Back off locknut from Compatible Fitting

onto tube. Cut fitting between threads and seal

ring head as shown in Fig. 8. Remove tubing section

remaining in threaded portion of fitting. Discard

locknut.

Clean, flux, and insert new tube end into remain

ing portion of Compatible Fitting. fVrap valve base

in wet rag. Heat and apply low-temperature (450 F)

solder.

SWEAT CONNECTION — Frontseat unit service

valves. Relieve refrigerant pressure from tubing.

Clean and flux area around leak. Repair using low-

temperature (450 F) solder.

Evacuate or purge evaporator coil and tubing

system. Add refrigerant charge. See Refrigerant

Charging instructions described previously.

Condenser Fan Adjustment

— Required fan

position is shown in Fig. 9. Adjust fan by loosening

setscrew(s) and moving fan blades up or down.

Fig. 9 — Condenser Fan Position

10