Carrier 50EQ User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

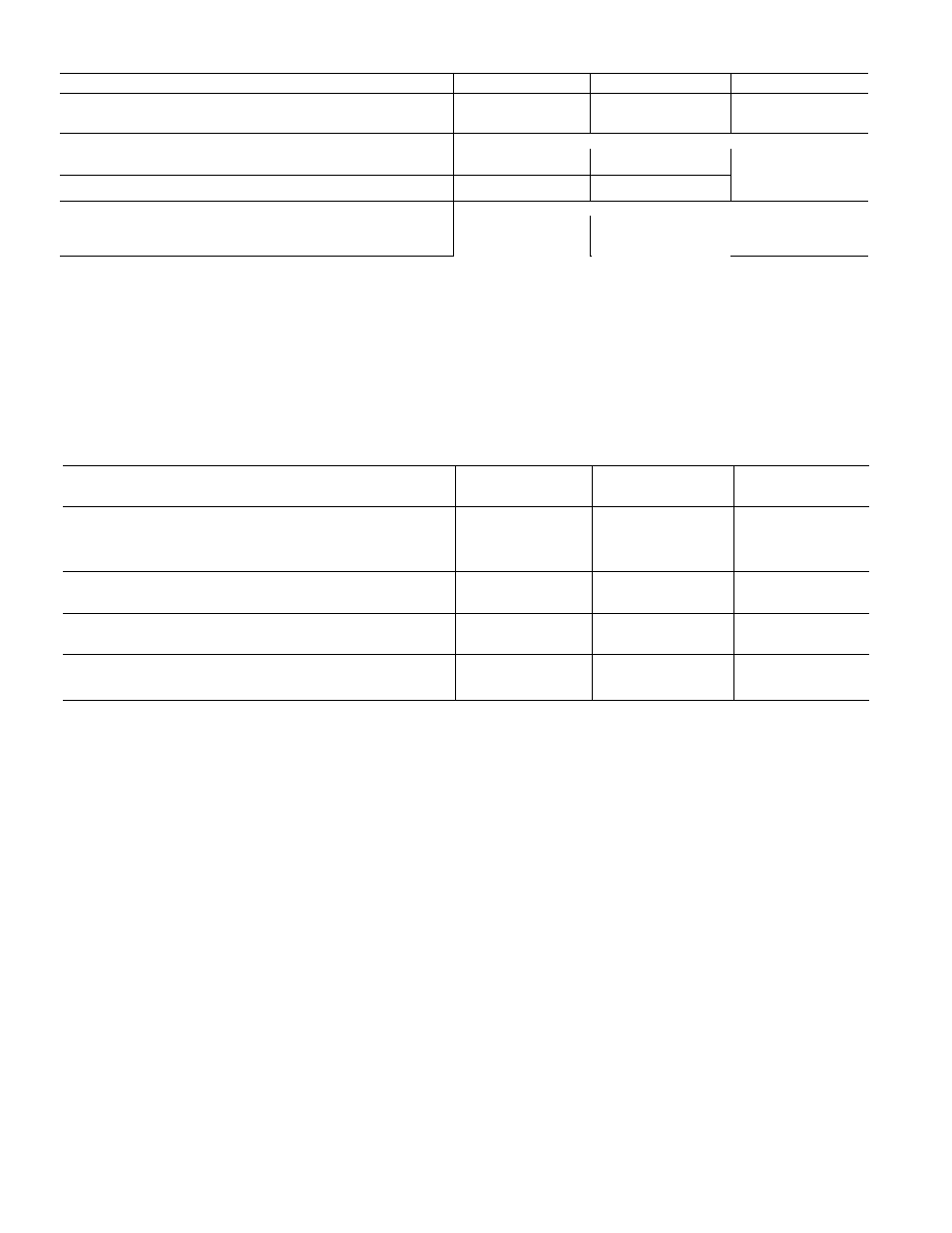

Table 1 — Physical Data

UNIT MODEL

50EQ024

50EQ028

50EQ034

OPERATING WEIGHT (lb)

Base Unit

3300

3900

4550

Base Unit with Economizer

3450

4075

4750

COMPRESSOR

Serviceable, Reciprocating Hermetic

No. .Model

2 06D824

2. 06D328

2 06D537

Oil (3GS or B1) pts (per Compr)

10

10

10

REFRIGERANT CHARGE

R-22

R-22

—

Sys 1*...Sys 2 (lb)

20.0...21.3

23.5..24.0

29.1..29.1

OUTDOOR AIR FANS

Direct Drive, Propeller

No. ...Hp

2 . 1

2 . 1

3 1

Frame (NEMA)

56T

56T

56T

Rpm (1-Phase)

1050

1050

1050

IIMDOOR AIR FANS

Motor

Shaft Diam (in.) — RPM 1750

Motor Frame Size

Motor Pulley Pitch Diam (in.)t

Fan Pulley Pitch Diam (in.)

Fan Speed (rpm)

Fan Shaft Diam (in )

Belt No. ...Size

Std

Opt

Std

Opt

Std

Opt

Std, A,B

Opt, A,B

Std

Opt

Std, A,B

Opt, A,B

Std

Opt

5

7-1/2

1

-

1 / 8

1-3/8

1S4T

213T

6 5 6 0

5 3 5 6

106

8

1073

991

1159 1225

1-3/16

2 3V750

2 3V670

1300

Fixed Speed Centrifugal

7-1/2

10

1-3/8

1-3/8

213T

215T

6 5 60

5 6 60

10 6

8

1073

991

1225 1312

1-3/16

2 3V750

2 3V670

1300

ELECTRIC HEATERS

Heat Anticipator Setting

Stage 1 ...2

9 25

9 25

9 25

HIGH-PRESSURE SWITCH

Cutout (psig)

Cut-in (psig)

428

320

428

320 ± 20

428 .jQ

320

LOW-PRESSURE SWITCH

Cutout (psig)

5+3

5 ± 3

5 + 3

Cut-in (psig)

20 ± 5

20 ± 5

20 + 5

INDOOR AIR FILTERS (2-in.)

Standard; No. ...Size (in.)

Throwaway; No. ...Size (in.)

6 20x25

6. .16x25

18 16x25

9 20x25

12 16x25

AIR INLET SCREENS

Manual Damper; No. ...Size (in.)

_

Economizer; No. .. Size (in.)

3 20x25

4 20x25

5 20x25

10

15

1-3/8

1-5/8

215T

254T

6 5 5 6

5 3 5 6

10 6

8

1073

925

1159 1225

1-11/16

2 3V750

4 3V710

1300

*System No 1 is bottom portion of indoor coil

fStandard fan motor supplied with standard fan drive pulleys and belts, optional fan motor supplied with optional

fan drive pulleys and belts Pulley A is installed in unit; pulley B is shipped with unit

3. Insert hood flange between unit top panel flange

and unit. Slots are provided in hood flange to

clear sheet metal screws. Tighten sheet metal

screws.

4. Secure hood side panels to outdoor air opening

flanges using screws provided.

5. Install hood support bracket(s) between U-

channel and support channel.

6. Install screen retainer on support channel using

screws in the slots. Do not tighten.

7. Install outdoor air screens.

8. Push retainers snugly against screens and tighten

screws.

Enthalpy Control

— Remove enthalpy control

assembly (Fig. 5) from shipping location on hori

zontal deck in return air filter compartment.

Using 4 no. 10-1 /2 screws from envelope in con

trol assembly junction box, mount the enthalpy con

trol assembly to the inside of economizer hood side

panel nearest condenser section (Fig. 6).

Route the 3 wires, coiled near top cover on the

condenser partition, thru knockout in side plate

(Fig. 6). Using wire connectors from envelope in

junction box, wire enthalpy control assembly as

shown in Fig. 7. Use strain reliefs from envelope in

junction box on side plate and junction box (Fig. 6).

Exhaust Air Hood Installation

— The optional

power exhaust package hood assemblies and re

quired sheet metal screws are shipped in compart

ment at right of indoor air fan motor.

Using screws provided, install a hood assembly

over each exhaust air opening as shown in Fig. 3.

Power exhaust applies only to units with econo

mizer. The exhaust fan and motor assembly is

factory wired and adjusted. Refer to Service, Ex

haust Air Fan Adjustment if required.

Return Air Filters

— Check to be sure return air

filters of the correct type and size are installed in

unit filter racks. Filter data is shown in Table 1. Do

not operate unit without return air filters.