Table 5 — indoor air fan pulley data, Economizer adjustment – Carrier 50EQ User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Indoor Air Fan Adjustment

— Fixed fan speeds

are shown in Table 1; note that second pulley is

shipped with unit. For other fan speeds, select field-

supplied motor or pulleys from Table 5.

Table 5 — Indoor Air Fan Pulley Data

UNIT

50EQ

FAN

RPM

MOTOR

PULLEY

FAN

PULLEY

No. Grooves - Type - In.

024

028

!

325 ! 2

■■ 33T r

2 -

i 107.3 T.2.

i 1093 t 2■

f 1159 f2-

1 .122.5: . .2 •

I 1300 j 2

'■"“sis

; 985

' T067.

j 1088

! 1153

:

■■ Ì30S

3 V - 5 . 6 ! 2 ■

3V - 6.0 f2 -

3V - 6.5 1

2

:

3V - 5.0 i 2 ■

3V - '5.3

[ 2

•

.3V,t5.6 J2.

3y - 6.0 i 2

3V - 5.6

3V.'6,0

3V - 6.5

3V - 50

3V - 5.3

5.6 ■{

3V-:60

BELT

NO - SIZE

3V-10 6

2

3V-m'5T2’-

3V.- 10..6.T.2 :

3V - 8 0 : 2 -

3V- "8X1 |2-

.3y..-...8..0...{.2.;

3V - 8.0 [ 2 _ -

3V -T0.6"'t 2 -

3V-T0.6'{2’-

3V-10,6

|2-

3V - 8 0 i 2 -

3V - 8.0 ! 2 •

3V- 60 5 2'-

■3V - 9.0 .2 ■

3V - 710

SV'^TSO'

3y..-..790.

3V - 670

3r-'670-

.3v -:mo

3V-J10

3V - 710 '

9V

-750"

'3V.-.750

3V - 670

3V - 670

3^-670.

034

: 925 1 2-

1073 I 2 -

i 1093 I 2 -

i 1159 f 2 -

; 1226 : 2'

i 1300 ; 2

J

3V: - SJS. \

2-

3V - 6.6 1 2 -

3V - 5 0 r 2

f2"

3V - 5.6 I 2 -

3V - 6 0 I 2 ■

3V-10.6 Ì 2

3V - 10,6 12 -

3V - 8.0' i 2"

3V- 8.0" p

3V- 8,0, i 4

3V - 8 0 i '2

3V--750-

3V-750.

■3V-'670

:3V-710

3Y.Ì 710.

3V - 710

Shaded values indicate standard or optional pulley com

binations available as shown in Physical Data table All

other combinations are field supplied

PULLEY REMOVAL — Pulleys are of the fixed

type. To remove, shut off unit power. Loosen fan

motor mounting plate and remove belt. Remove

pulley from shaft.

After reinstalling pulley and belt, check pulley

alignment and belt tension as described below.

PULLEY ALIGNMENT ^ Loosen fan shaft pulley

bushing and slide pulley along shaft. Make angular

adjustment by loosening motor mounting plate and

repositioning it as required.

BELT TENSION — Adjust belt tension by moving

motor back until only a SLIGHT BOW appears in

the belts on the slack side of the drive while running

under full load. Secure motor. Recheck belt tension

after 24 hours of operation, adjust as necessary.

Exhaust Air Fan Adjustment

— Adjust belt ten

sion so that 1/8-in. deflection at 5- to 8-lb pressure

between pulley centers can be obtained. To change

tension, loosen motor mounting bolts, reposition

motor and tighten mounting bolts. Tighten locknut

and bolt under motor mounting plate to secure in

fixed position.

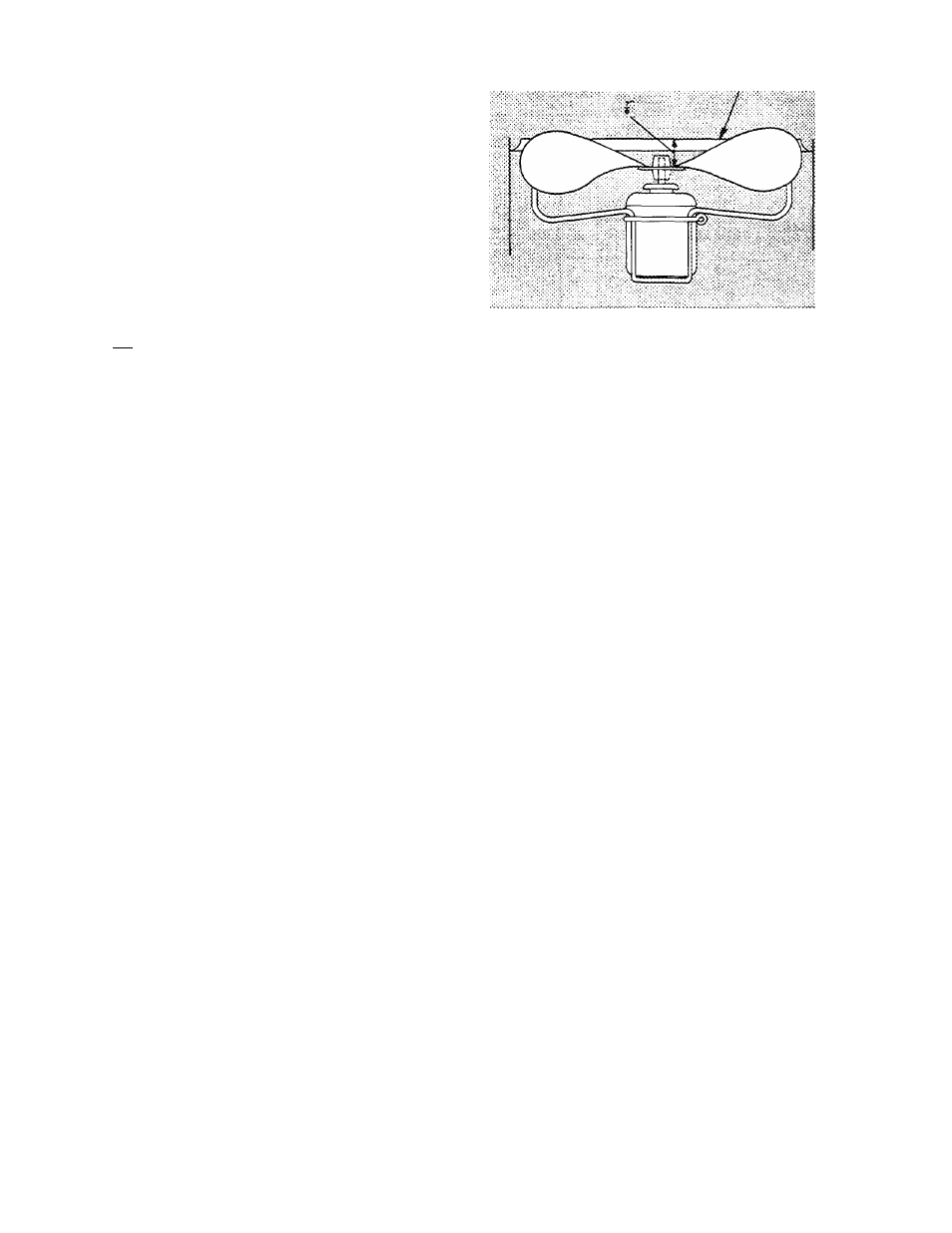

Outdoor Air Fan Adjustment

(Fig. 11) — Shut off

fan power supply. Remove fan guard and loosen fan

hub setscrews. Adjust fan height using a straight

edge laid across fan venturi. Tighten setscrews. Fill

hub recess with permagum to prevent hub from rust

ing to motor shaft.

fiSK OSCIC VEMTUSl

'i .

Fig. 11 — Outdoor Air Fan Adjustment

Economizer Adjustment

1. Set enthalpy control at its highest setting. If out

door temperature is above 70 F, perform the

following: Install jumper between enthalpy con

trol terminals 1 and 2 (red and yellow wires).

Remove control relay (CR) from unit econo

mizer control panel.

2. Set system selector switch at COOL and set

cooling temperature selector lever at lowest

setting.

Cooling mode may also be simulated by remov

ing the thermostat wires from terminals Y1 and

Y2 and installing a jumper between terminals R

and Yl.

3. Set mixed air thermostat at its lowest setting.

Outdoor air damper will go to fully open position

(indoor air damper closes).

4. Set mixed air thermostat at its highest setting.

Outdoor air damper will go to fully closed posi

tion (indoor air damper opens).

5. Adjust mechanical linkage if necessary, for

correct positioning (Fig. 12). If enthalpy control

terminals were jumped and plug-in control relay

was removed from unit control box in step 1,

remove jumper and replace plug-in control relay

after positioning dampers. If cooling mode was

simulated as described in step 2, be sure to re

move jumper and reconnect thermostat wires

to Yl and Y2.

DAMPER VENT POSITION SETTING

1. Set fan switch on thermostat assembly at FAN

(continuous fan operation) and close night

switch (if used).

2. Set thermostat system selector switch at OFF.

3. Remove cap from vent adjustment screw on top

of damper motor terminal box cover.

Turn adjustment screw slowly until dampers

assume desired vent position. Do not manually

operate damper motor. Damage to motor will result.

10