Carrier 58BB User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

3. When adding a low voltage humidifier to the

system, install a plug-in humidifier relay in

receptacle HR on the control center. Connect

humidifier directly to terminals H and H on the

low voltage terminal strip. Connect leads from

low voltage humidistat, in the conditioned

space, to terminals HS and HS on the low

voltage terminal strip.

IMPORTANT; Set adju.stabie heat antic

ipator (if provided) to agree with ampere

value of combination ga.s vaive. Failure to

make adjxisiment will result in unsatisfac

tory temperature control.

VALVE

|

heat

ANTSOPATOR

\ SETTWÇ

Essex XA^lpho'Taico) T;F 555

ünîftoi 700Û

i • 0.4So

1 G.20o

^ COMBUSTION AIR ^ See NFPA No. 54.

1. If furnace is installed in a confined area, such as

a closet or utility room, provide air for

combustion.

a. Provide two air openings to interior space of

equal area, one located near the top of the

enclosure and one at the bottom.

b. Make sure that openings have free area not

less than l O O s q i n . in area, plus an addi

tional 1 sq in. for each 1000 Btuh in excess

of 100,000 Btuh input.

c. Where openings to interior spaces are im

practical, follow the methods outlined in

NFPA No. 54.

2. If furnace is installed in an unconfined area,

such as in a full basement, it can normally be

assumed that infiltration will provide sufficient

air in building of conventional frame, brick or

stone construction. In buildings of unusually

tight construction, provide a permanent open

ing to the outdoors with a minimum free area

of not less then 1 sq in. per 4000 Btuh total

input ratings of all appliances in space.

3. Consult local codes for special requirements.

CAUTION: Whenever gas appliance is installed

in any area where corrosive atmosphere or

chlorine or chlorinated compounds are present,

bring combustion air into combustion area of

furnace from outdoor source. Failure to do this

can cause excessive corrosion in furnace heat

exchanger.

CIRCULATING AIR SUPPLY

ordinances and NFPA No. 54.

Consult local

1. Do not take circulating air from same space as

combustion air Supply may be any mixture of

outdoor and return air with minimum tempera

ture of 50 F.

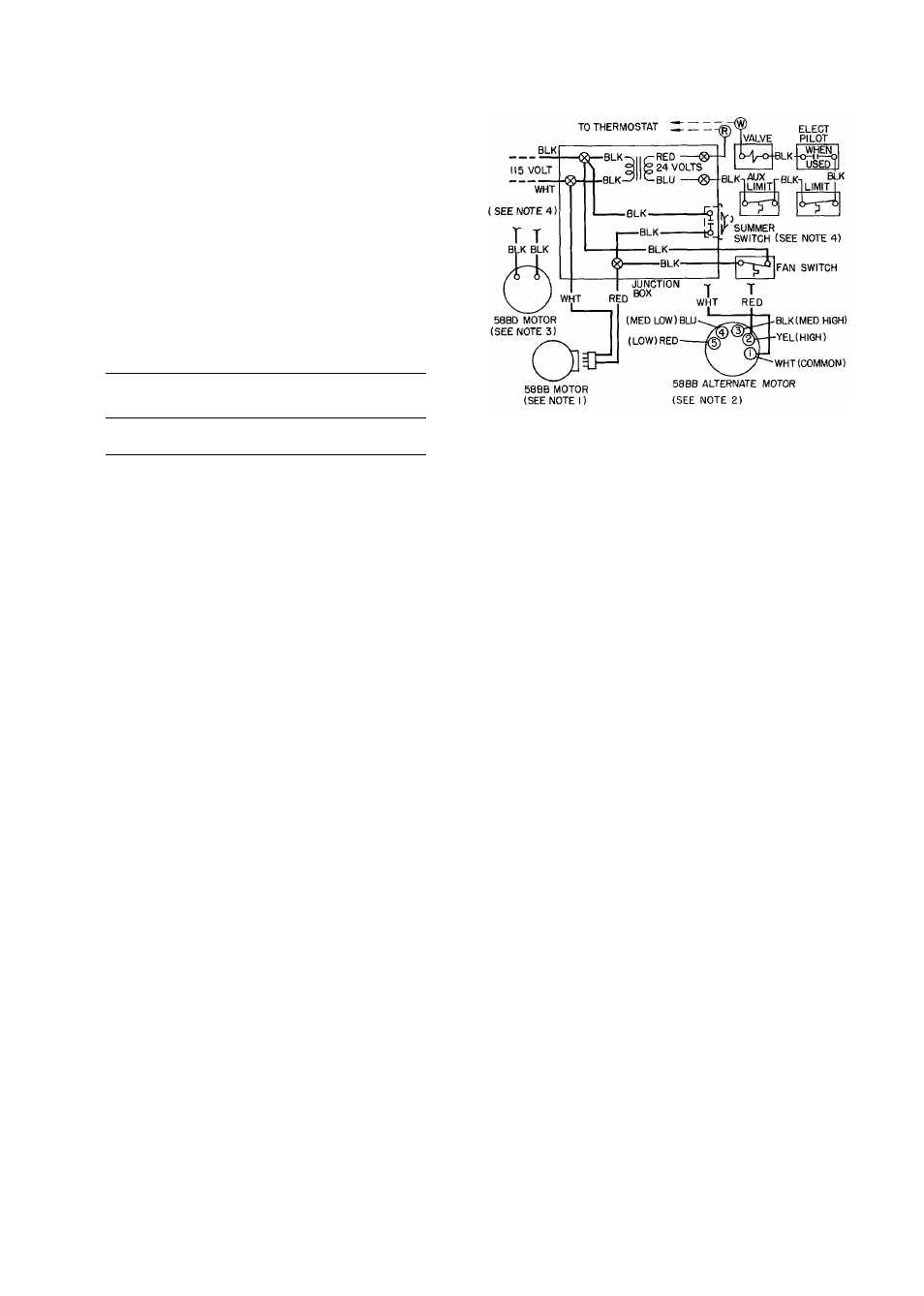

LEGEND (Common for Fig. 5 and Fig. 6)

___ Field Power Wiring (115 Volt)

. Factory Power Wiring (115 Volt)

— Printed Circuit Control Center Wiring (11 5 Volt)

----------Field Control Wiring (24 Volt)

---------- Factory Control Wiring (24 Volt)

—.— Printed Circuit Control Center Wiring (24 Volt)

0

Screw Terminal — Field-Connection Points (115 Volt and

24 Volt)

Ш

’4-in

Quick-ConnectTerminal

-

Factory-Wired

Connections

(115 Volt and 24 Volt)

NOTES;

1

To change tow speed, pull out speed selector plug and plug in with

desired speed marking facing away from motor shaft.

2

To change motor speed, move red lead to desired terminal on

motor

CAUTION: Do not move w/iire wire. Do iwt operate or>

"High" speed unless cooiiog coii ie used.

3

Wire ¿itocA: 58BD motor leads as indicated forwhiteand red 58BB

motor leads

4

Knockout provided for field installation

5 Total electrical load is less than 1 2 amps

6

Whenever replacing original wire supplied with furnace, use

AWM

(90

C with 3/64-in thick insulation for 24-volt and

4/64-in thick insulation for 115-volt) wire or its equivalent

7 Motor(s) furnished with thermal overload protection

Fig. 5 — 58BB.BD Field Power and Control Wiring,

Heating Only Diagram

2. Install ducts and diverting dampers so that

volume of circulating air entering furnace is

unrestricted.

3. Bring return air connection thru top of furnace.

Where there is no complete return duct system,

run return air duct full size to location outside

enclosed area. Return air plenum must extend a

sufficient height above 14 in. required for filter

removal to provide for attachment of return air

duct or grille.

,4