Carrier 58BB User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

DUCTWORK RECOMMENDATIONS

1. Install locking-type dampers in all branch or

individual ducts to balance out system.

2. Use tapered fittings or starter collars between

ducts and plenum.

3.

Use flexible duct connection (asbestos cloth)

between furnace and discharge plenum.

4. Install acoustical insulation in warm air plenum;

install sound traps in short run ducts.

5. Run return air connections under floor or I'un

full size return from space outside enclosed

area. If outdoor air is used, combination of

outdoor and return air requires duct design and

diverting dampers so installed that volume of

circulating air entering furnace cannot be re

duced or restricted below that which would

normally enter thru circulating air intake of

furnace

FILTERS — Filters are shipped from factory in

blower compartment of furnace. (See Fig. 3.) To

gain access, remove top front panel and filter

compartment doors located at right- and left-hand

sides of vent. Install by raising filters above right-

and left-hand side of blower and positioning on

filter rack as shown in Fig. 3. As an aid in filter

removal, an access panel could be field fabricated

in the front of the return air supply plenum.

VENTS — Vent furnace to permanent chimney or

thru roof with vent of approved design. (Type B

vent is recommended.) Observe local ordinances.

1. Size flue pipe connections same as furnace

vent connection. (See Fig. 1 and Table 1.)

2. Run pipe as directly as possible with minimum

number of turns.

3. Maintain minimum pitch of 1/4 in. per linear

ft on horizontal runs. Pitch should not exceed

75% of vertical vent.

4. Maintain minimum angle of 60 degrees from

vertical for vent pipe crossovers in attic.

5. Rigidly support pipe with hangers or straps.

6. Do not connect into a chimney serving an

open fireplace.

7. If chimney is used, total equivalent straight

length of flue piping between furnace and flue

pipe connection at chimney must not be

greater than 75% of vertical height of chimney

above flue pipe connection.

8. Install flue pipe to extend thru chimney wall

but not beyond inside wall of flue.

9. Minimum vertical stack height is 5 ft. Extend

flue pipe at least 3 ft above roof and 2 ft above

any object within a 15-ft radius. Ensure that

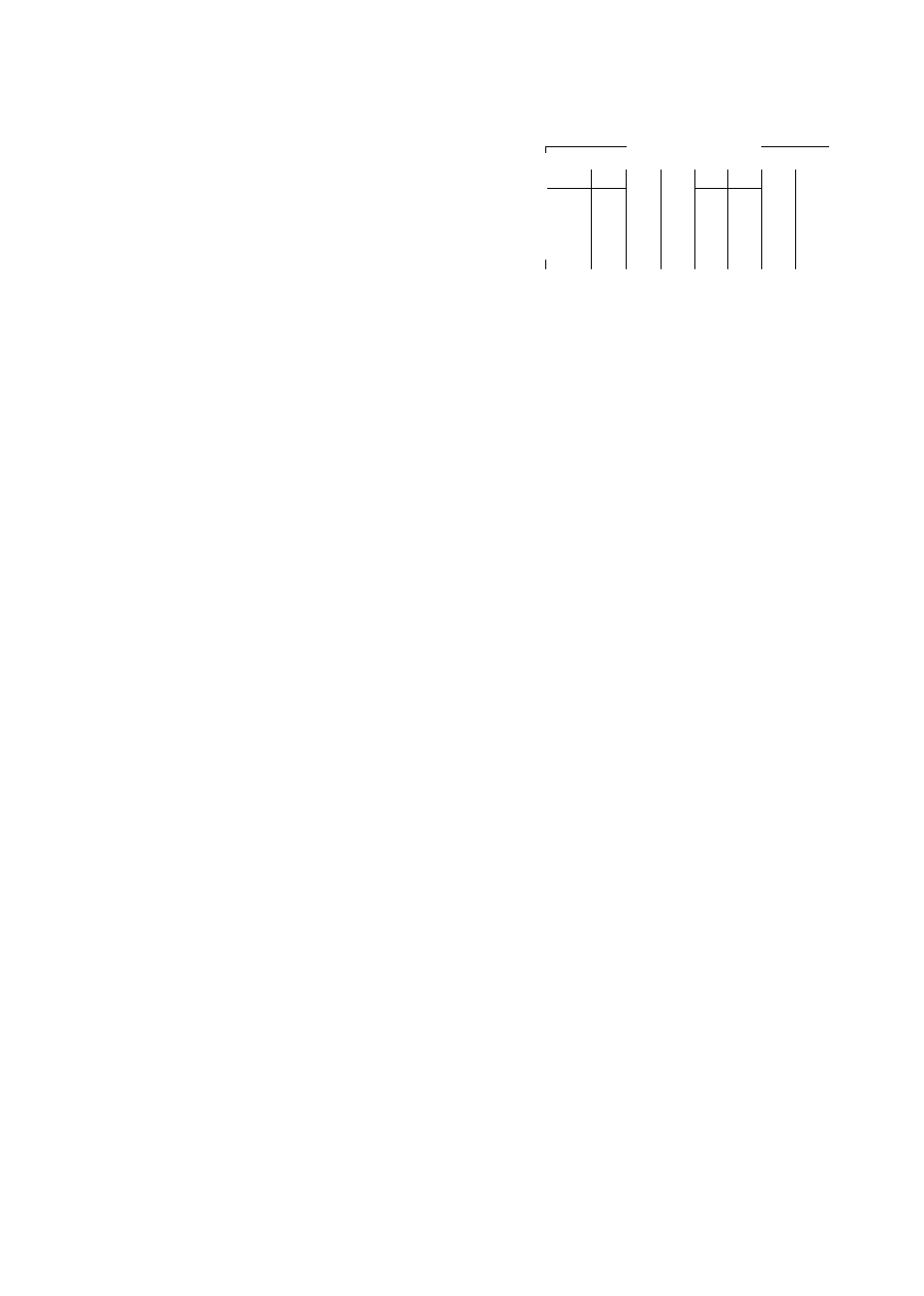

Table 4 — Pipe Sizing*, Capacity For Natural Gas,

Cu Ft/Hr

PIPE

LENGTH (ft)t

10

20

30

40

50

60

70

80

132

92

73

63

56

50

46

43

278

190

152

130

115

105

96

90

520

350

285

245

215

195

180

170

1050

730

590

500

440

400

370

350

X — J

___

_-,J

PIPE SIZE

’4

1

U/4

*Based on pressure drop of 0 3 in. wg, 0 6 sp gr gas

fWithout elbows

NOTE: For pipe sizing capacity for LP gases, refer to NFPA No. 54

vent outlet terminates in an approved cap with

a venting capacity not less than that of the

vent. (See Table 1 for vent sizes.)

10. Insulate flue pipe where it passes near com

bustible material. Underwriter’s Laboratories

(UL) require that uninsulated flue pipe be

installed with a minimum clearance of 6 in.

from

combustible

materials.

Vent

piping,

which meets with National Board of Fire

Underwriter’s Specifications for type B vents,

may be installed with a clearance of 1 in. from

combustible materials.

If other gas appliances are vented into

common flue, flue area must equal largest vent area

plus one-half total areas of other vent conneetors.

GAS PIPING — Install piping per national and local

codes, and NFPA No. 54.

1. Furnish gas line from main gas supply to

furnace.

2. Size supply pipe per volume of gas used and

allowable pressure drop. (See Table 4.) Supply

pipe size must at least equal that of furnace gas

connection.

■ 3. Refer to NFPA No. 54 for additional suggested

methods of piping.

a. Install drop pipe adjacent to, but not in

front of furnace.

b. Install manual shutoff valve on gas piping

per local codes.

c. Install tee in pipe at same elevation as gas

inlet connection to unit; provide ground

joint

union

between

tee

and

furnace

controls.

d. Extend drip leg and cap it.

e. Test for pressure and leaks.

CAUTION: Never rise open flame for testjxig.