Table 2 — blower data, Installation location selection – Carrier 58BB User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

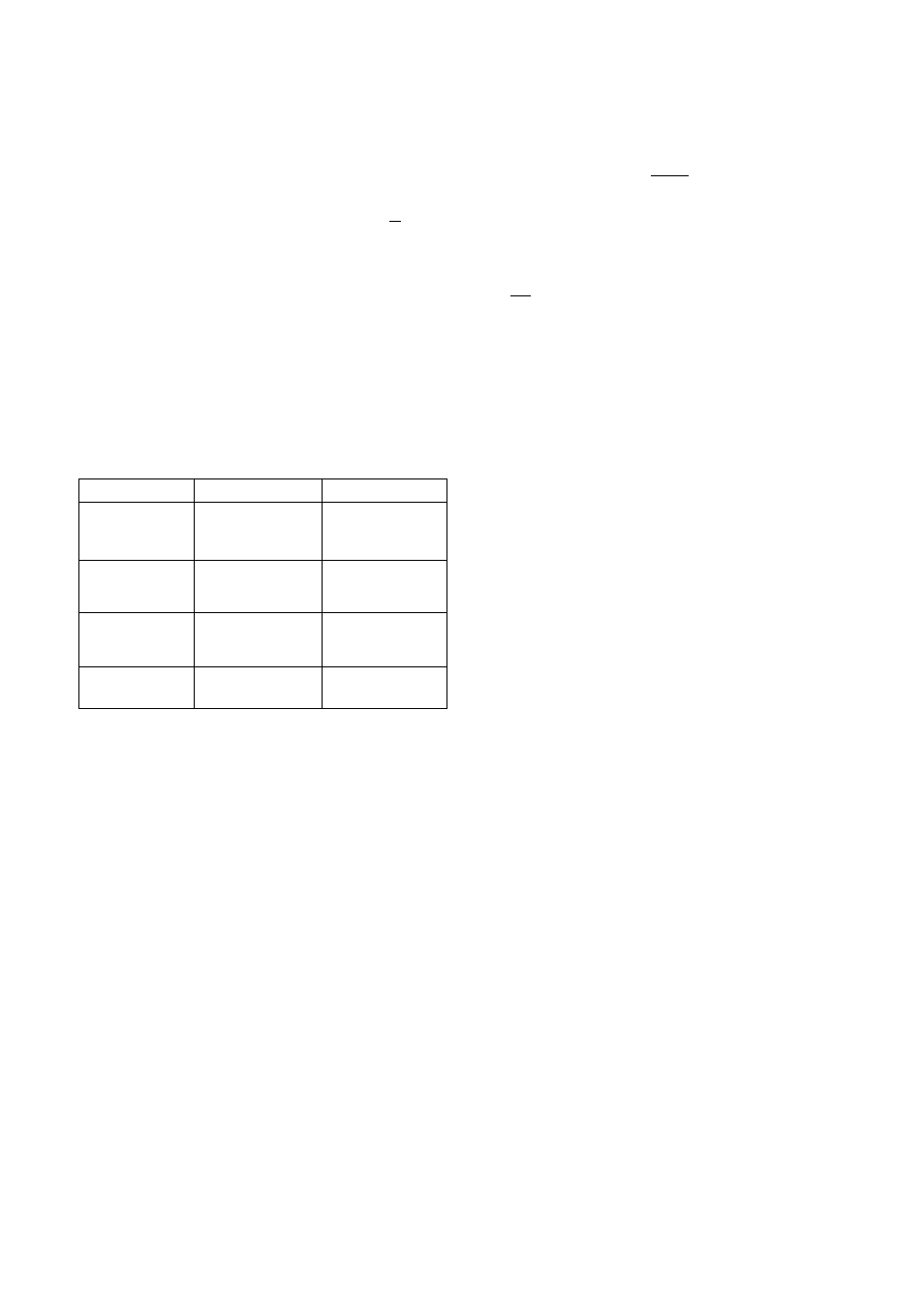

Table 2 — Blower Data

BLOWER

BB DIRECT DRIVE

BD BELT DRIVE

FURNACE 58

080

100

120

080,100

125

150

SERIES

MOTOR

Nom Size (in.)

Hp

PPD

BL

BMPS*

ESP (in. wg)t

Air Delivery (max cfm)1

100,400

9x8

.20

730"

„ . 3 0

650

200,500

100,400

J0x8

9x8

Ve

.20

1100

50

1020

20

890'

_^0

760

200,500

100,400

J

0x 8

V

3

9xj0

Ve

.20

1180

.50

1070

.20

1080

.30

920

200,500

200,500

j o > i

!0

V

3

10x8

"36"

.20

1250

.50

.20

1200

.50

980 1120

12x9

^ Al

42

.20

.50

260 1380

J2xU

^ 1

" "41 ‘

_4_

.20

J„„

.50

1620 1800

BL — Belt Length

BMPS — Blower Motor Pulley Setting (turns open from closed position)

ESP — External Static Pressure

PPD — Pulley Pitch Diameter (range 2.1 — 2 9 in )

*Do not close blower motor pulley beyond setting shown

fFilter in place

:fWith motor set at "High" speed

NOTE; Referto Application Data literature for fan performance curves.

Table 3 — Furnace-Coil-Plenum Combinations

FURNACE

COIL

PLENUM

58BB080,

58BB100,

58BB120

28AF002

28AE,AF003

28AE,AF004

28AE900051

58BD080,

58BD100

28AF002

28AE,AF003

28AE,AF004

28AE900051

58BD125

28AE,AF003

28AE,AF004

28AE,AF005

28AE900051

58BD150

28AE,AF005

28AE006

28AE900061

INSTALLATION

Location Selection

NOTE; Adapters not required.

Series 100 and 200 units are tested and

approved for use with natural gas. Series 400 and

500 are factory built and approved for use with

100% propane gas. Firing of these units with any

other gas or mixture is not approved.

Furnaces are shipped fully assembled, including

built-in draft diverters. Heating/cooling models are

equipped with a printed circuit control center,

which provides a central control connection point

for furnace components and field-added acces

sories. All internal electric and gas controls are

factory assembled and wired.

When unpacking unit, should any in-transit

damage be observed, file claim with transportation

agency.

This publication covers furnace and non

combustible base installation. It also shows ter

minal connections used for wiring accessories to

furnace. For accessory installation details, refer to

applicable installation literature.

When selecting a location for the furnace,

observe the following:

1. Install furnace close to chimney and as central

ized as possible with respect to distribution

system.

2. Locate cooling coil (if used) downstream from

furnace.

3.

Ensure adequate door clearance for service

access.

4. Ensure adequate ventilation. (See Combustion

Air.)

5. Follow local and national utility codes.

a. Allow safety clearance of 1 in. from sides,

top and type B vent; 6 in. from unlisted

vent; 0 in. at rear.

b. Provide service clearance of 30 in. at front

of unit.

c.

Downflow furnaces are not approved for

installation directly on combustible floors.

Unless furnace is set on a concrete slab

floor, use of a noncombustible base is

required. (See Fig. 2.) Noncombustible base

is available as an accessory package. If

furnace is combined with a cooling coil,

plenum can serve as the noncombustible

base.

d. If furnace is to be installed on the first floor

of a house built over a crawl space, make

sure that unit and noncombustible base (if

required) will rest on supported floor joists.

Otherwise, vibrations could be set up, result

ing in unnecessary and undesirable noises.

e. Make sure that a positive air seal is made on

all four sides of the furnace.