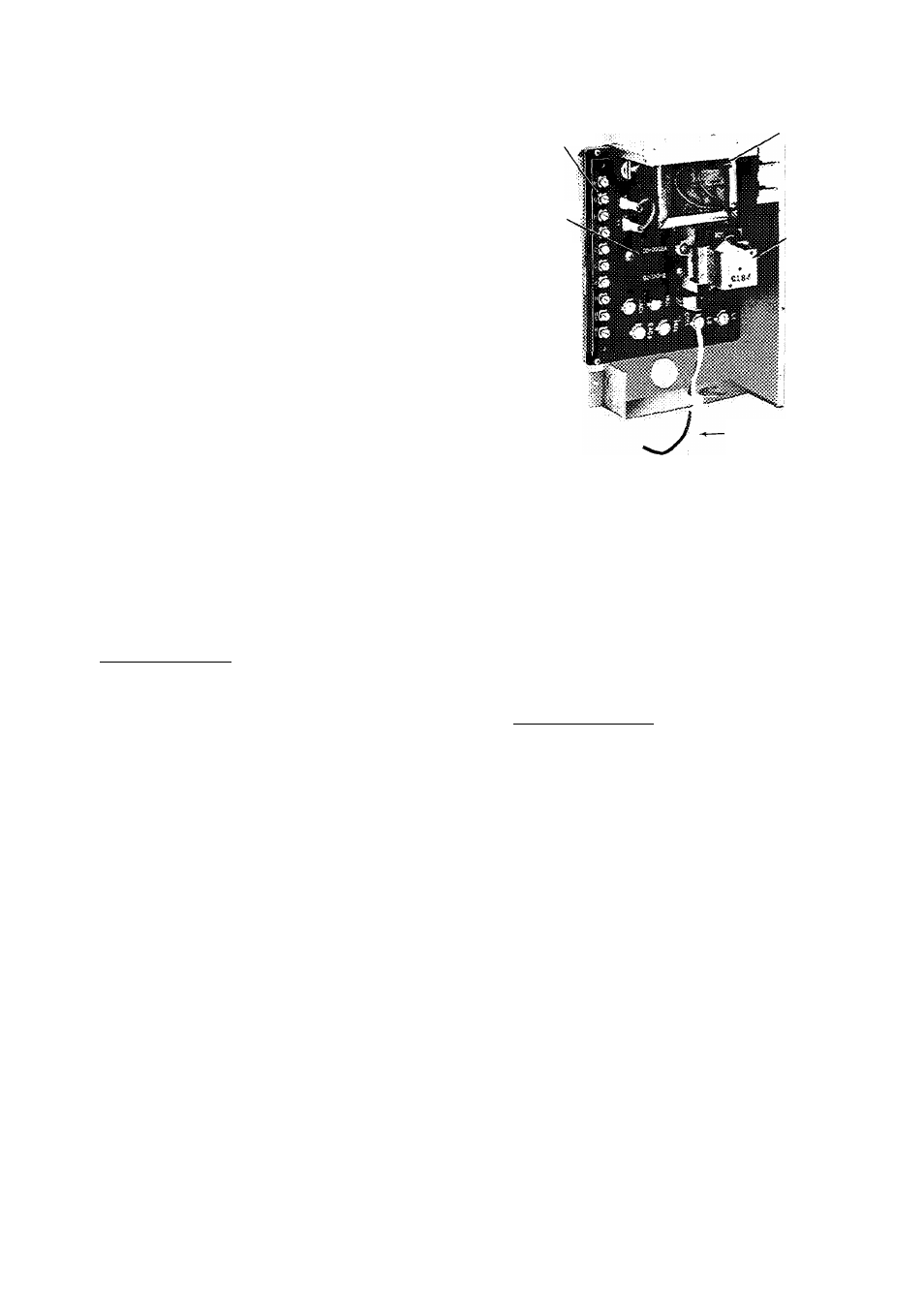

Fig. 4 — printed circuit control center – Carrier 58BB User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

'\

WIRING — Fig. 4 shows the printed circuit control

center, which is factory-installed on heating/

cooling furnaces. Fig. 5 illustrates the field power

and control wiring for heating only furnaces; Fig. 6

illustrates the field power and control wiring for

the heating/coohng models.

When wiring units, make sure that all national

and local codes are followed. Check against loose

wiring connections.

When making aluminum conductor connections

to copper conductors or terminals, use only con

nectors which are UL approved for the application.

(UL approved connectors will be tin plated, have

separator bars for placement between conductors

to prevent direct contact between aluminum and

copper, and have large bearing surfaces to minimize

unit pressures for minimum cold flowing of the

aluminum and subsequent loosening of the joint.)

After insulation has been stripped from alumi

num conductor, coat conductor end with corrosion

inhibitor (Burndy “Penetrox A” or equivalent),

and wire brush aluminum surface thru inhibitor.

After cleaning, recoat aluminum conductor

with inliibitor, and make up connection. (Coat

entire connection.)

If applicable, wrap connection for moisture

andjor electrical protection.

Field Power Wiring — (See Fig. 5 and Fig. 6.)

Heating Only Models

1. Connect separate 115-volt, single-phase, 60-Hz

power supply thru hole in side of unit casing to

115-volt pigtails.

2.

If required by local codes, install fuse and

manual switch between main box and furnace.

Heating/Cooling Models

(With Printed Circuit Control Center)

1. Connect separate 115-volt, single-phase, 60-Hz

power supply to terminals Lj and L2 on the

printed circuit control center. (See Fig. 4.)

2.

If required by local codes, install fuse and

manual switch between main box and furnace.

3. When adding an electronic air cleaner to the

system, connect air cleaner to terminals EACi

and EAC2. These terminals supply 115-volt

power to the electronic unit.

4. When adding a line-voltage humidifier to the

system, connect humidifier to terminals HUi

and HU2.

Humidifier has its own control wiring, which is

independent of the furnace, except for the

power connections provided at HUj and HU2-

5. When replacing a single-speed motor with a

dual-speed motor, be sure to remove jumper

between HI and LO on the control center.

LOW VOLTAGE

TERMINAL STRIP

HUMIDIFIER

RELAY

RECEPTACLE

(SEE NOTE 2)

40-VA TRANSFORMER

(STANDARD

COMPONENT)

PLUG-IN

BLOWER

RELAY

(STANDARD

COMPONENT)

LINE VOLTAGE

CONNECTIONS

NOTES:

1 All factory-wired connections are !4~in quick-connect terminals:

all field-connection points are screw terminals.

2 Optional component, humidifier relay, is plugged into receptacle

HR when low voltage humidifier is added to system.

Fig. 4 — Printed Circuit Control Center,

Cover Removed

Field Control Wiring — (See Fig. 5 and Fig. 6.)

Heating Only Models

1.

Connect two 24-volt leads from accessory

thermostat to low-voltage pigtails R and W.

2.

For constant fan operation, turn summer

switch, located on the furnace junction box, to

the “On” position.

Heating/Cooling Models

(With Printed Circuit Control Center)

1. For heating with constant fan control, connect

leads from room thermostat subbase to ter

minals W, G, and R on the low voltage

terminal strip. (See Fig. 4.) This hook-up is

used when heating only with manual fan

control at the thermostat is desired.

2. Connect accessory thermostat to furnace and

cooling unit. Connect terminals W, G, R and Y

on the thermostat subbase to identically labeled

terminals on the low voltage terminal strip.

Connect yellow and black low voltage leads

from the remote condensing unit to the two C

terminals on the low voltage terminal strip.