Service, A caution – Carrier 38HD User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Charge System — Release holding charge into sys

tem by opening (backseating) liquid and suction line

service valves. Add charge amount as required for the

total system. See Table 1. For indoor sections not in

cluded in Table 1, see Refrigerant Charging.

To Start Unit — Assuring that crankcase heater has

been on for 24 hours, and field disconnect is closed, set

room thermostat below ambient. Unit compressor starts

after a 5-minute delay if equipped with optional Time

Guard® 11. Operate unit for 15 minutes, then check

system refrigerant charge. See Refrigerant Charging.

SERVICE

A

CAUTION

Before performing recommended maintenance, be

sure unit main power switch is turned off. Failure to

do so may result in electric shock or injury from

rotating fan blade.

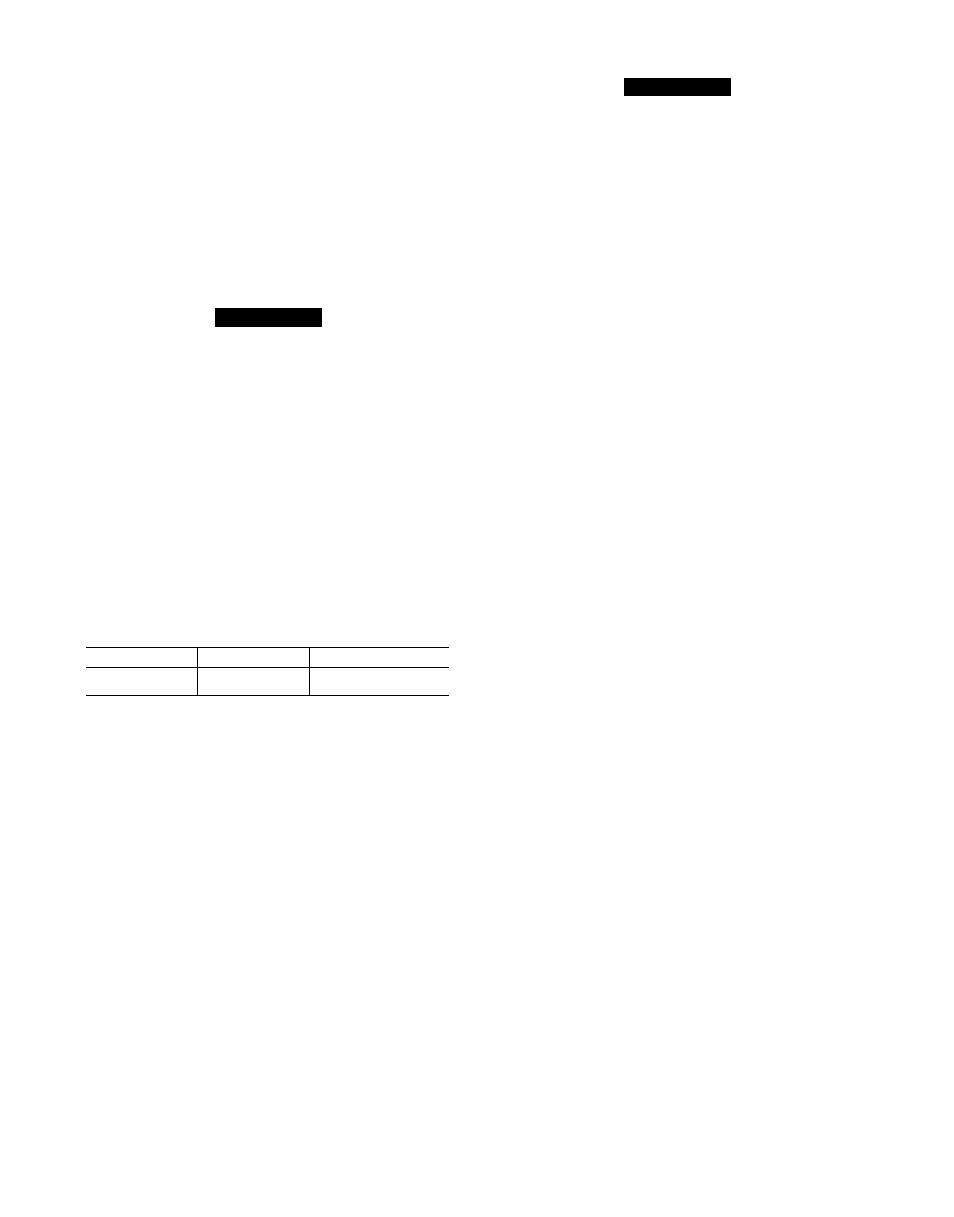

Condenser Fan is held by a reinforced wire mount

which clamps the fan motor in position. See Fig. 8 for

proper mounted fan position.

I 1

I I

I I

n I .

-FAN BLADE

T

OUTSIDE EDGE OF

FAN DECK

OUTSIDE EDGE

OF GRILLE

, Q a n a n a

Q Q f. a

DIMENSION FROM

OUTSIDE TOP EDGE OF

BLADE TO OUTSIDE EDGE

OF FAN DECK SEE

CHART BELOW

UNIT SIZE

38HD018

38HD024,030

38HD036,048,060

433" (11 mm)

709" (18 mm)

16" (4 mm)

Fig. 8 — Mounted Fan Positions

High Pressure Relief Valve is located in com

pressor. Relief valve opens at a pressure differential of

approximately 450 ± 50 psig between suction (low side)

and discharge (high side) to allow pressure equalization.

Internal

Current

and

Temperature

Sensitive

Overload resets automatically when internal com

pressor motor temperature drops to a safe level (over

loads may require up to 45 minutes to reset) When an

internal overload is suspected of being open, check by

using an ohmmeter or continuity tester. If necessary,

refer to Carrier Standard System Techniques Manual,

Chapter 2, for complete information.

Pumpdown Procedure — The system may be

pumped down in order to make repairs on low side with

out losing complete refrigerant charge.

1. Attach pressure gage to suction service valve gage

port.

2. Frontseat the liquid line valve.

3. Start unit and run until suction pressure reaches

5 psig (see Caution).

4. Shut unit off and frontseat suction valve.

5. Vent remaining pressure.

A

CAUTION

38HD unit coils hold only the factory designated

amount of refrigerant. Additional refrigerant may

cause units to relieve pressure through internal

pressure relief valve (indicated by a sudden rise of

suction pressure) before suction pressure reaches

5 psig. if this occurs, shut off unit immediately,

frontseat suction valve and vent remaining pressure.

Filter Drier — Whenever the moisture-liquid indicator

shows presence of moisture, replace filter drier. Refer to

Carrier Standard Service Techniques Manual, Chapter 1,

Refrigerants, for details on servicing filter driers.

High -Pressure Switch — This switch, located on

discharge line, protects against high discharge pressures

caused by such events as overcharge, condenser fan motor

failure, system restriction, etc. It opens on pressure rise at

about 426 psi. If system pressures go above this setting

during abnormal conditions, switch opens. Do not

attempt to simulate these system abnormalities, as high

pressures pose a serious safety hazard. High-pressure

switch is also checked with an ohmmeter similar to cheek

ing low-pressure switch. If system pressure is below

426 psi, switch shows continuity. It is replaced in same

manner as low-pressure switch. Observe all safety

precautions.

Low-Pressure Switch — This switch, mounted on

the suction line, has fixed nonadjustable settings.

TO CHECK — Attach pressure gage to suction service

valve gage port. Slowly close liquid shutoff valve and

allow compressor to pump down. Do not allow com

pressor to pump down below 2 psig (13.8 kPa). Com

pressor should shut down when suction pressure drops to

cutout pressure in Table 2, and should restart when

pressure builds up to cut-in pressure shown after CLO

(Compressor Lockout) has been reset and optional Time

Guard has completed its timing cycle.

Crankcase Heater prevents refrigerant migration and

compressor oil dilution during shutdown when com

pressor is not operating. If crankcase heater is de

energized for more than 6 hours, both compressor service

valves must be closed.

Crankcase heaters come in 2 basic types; wraparound

(bellyband) type that is wrapped externally around com

pressor shell, and insertion type that is inserted into

compressor oil well in shell of compressor. Both types

are in this family of units.

Crankcase heater is powered by high-voltage power of

unit. It is connected across the line side of the contactor

and operates eontinually. Use extreme caution trouble

shooting this device with power on. Easiest method of

troubleshooting is to apply voltmeter across crankcase

heater leads to see if heater voltage is on. Do not touch

heater. Carefully feel area around crankcase heater. If

warm, crankcase heater is probably functioning. With

power off, and heater leads disconnected, check across

leads with ohmmeter. Do not look for a specific resistance

reading. Check for resistance or an open circuit. Change

heater if an open circuit is detected.

Service Valves — The service valves in the condensing

unit come from the factory frontseated This means the

refrigerant charge is isolated from the line set connec

tion ports. To prevent damage to the valve, use a wet cloth

or other accepted heat sink material on the valve before

brazing.

The service valves must be backseated (turned counter

clockwise until seated) before the service port caps can be

removed and hoses of gage manifold connected. In this

position,

refrigerant

has

access

from

and

through

outdoor and indoor unit. The service valve cannot be