A caution, Step 4 — complete electrical connections, Caution – Carrier 38HD User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

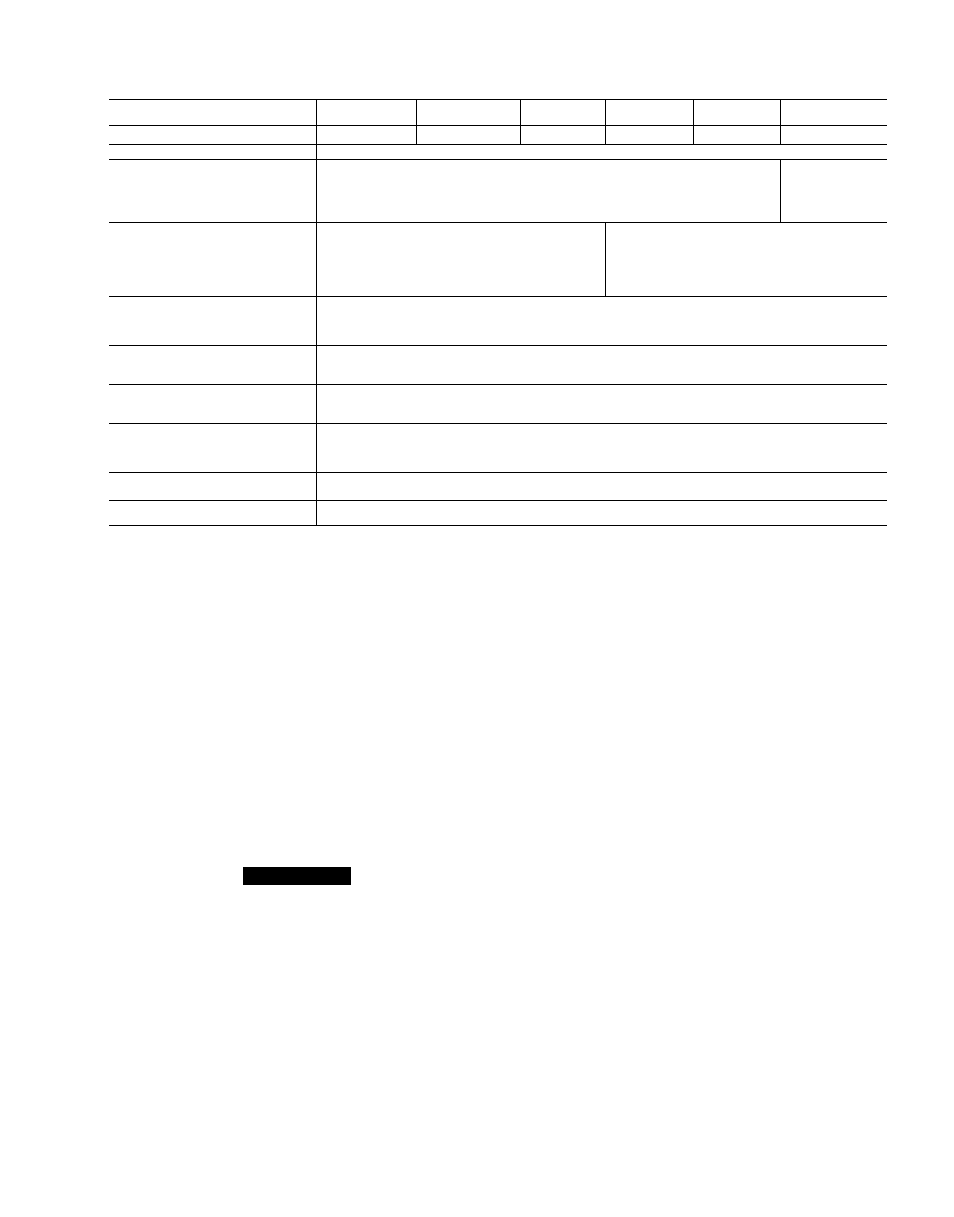

Table 2 — Physical Data

UNIT 38HD

018

024

030

036

048

060

OPER WT (lb), 1 ph/3 ph

148/*

160/*

171/*

240/226

244/235

244/235

REFRIGERANT

R-22

COMPRESSOR

Model

Oil (pts), initial/recharge

Crankcase Heater Watts

Hermetic

Tecumseh

I

Tecumseh | Carlyle I Carlyle I Carlyle

AW5519 AW5524 J30 | J36 | J48

32/30 32/30 46/44

40

Copeland

CRP5-0450

70/66

CONDENSER AIR FAN

Number — Rpm

Diameter (in.) — no. blades

Fan Pitch

Motor Hp (NEMA)

Nominal Cfm

Propeller, C

1 —

18 — 3

25

1

27

Vs

1835

1

1720

1

1750

)irect Drive

850

24 — 3

24

'A

3900

¿ONDENSER COIL

Rows

Face Area (sq ft)

Fins/in.

1

'/2 1

2 2

1

2

1

2

6 1

1

12.3

15

CONNECTIONS

Suction (in.), Sweat

Liquid (in.). Flare

% 1 % 1 %

%

LINE SIZES

Suction

Liquid

% %

1’/a

%

CONTROLS

Pressurestat Settings

ui_u Cutout

Cut-in

426 ± 7

320 ± 20

1

Cutout

Cut-in

7 ± 5

22 ± 5

FUSIBLE PLUG

210F

*Not applicable

should be installed just after liquid line shutoff valve.

Do not use a receiver (a receiver is not provided with unit

and one should not be used).

MAKE PIPING SWEAT CONNECTIONS — Remove

plastic caps from liquid and suction service valves.

Use refrigerant grade tubing. Service valves are closed

from the factory and ready for brazing. After wrapping

the service valve with a wet cloth, the tubing set can be

brazed to the service valve using either silver bearing or

non-silver bearing brazing material. Consult local code

requirements. Refrigerant tubing and indoor coil are now

ready for leak testing.

NOTE: Unit is shipped with R-22 factory holding charge

indicated on nameplate.

Pass nitrogen or other inert gas through piping while

brazing to prevent formation of copper oxide.

A

CAUTION

To avoid damage while brazing, service valves should

be wrapped with a heat-sinking material such as a wet

cloth.

PROVIDE SAFETY RELIEF — A fusible plug is

located in unit suction line. Do not cap this plug. If local

code requires additional safety devices, install as directed.

Step 4 — Complete Electrical Connections

POWER WIRING — Unit is factory wired for voltage

shown on nameplate. Provide adequate fused disconnect

switch within sight of unit, readily accessible, but out of

reach of children. Provision for locking switch open (off)

is advisable to prevent power from being turned on while

unit is being serviced. Disconnect switch, fuses, and field

wiring must comply with National Electrical Code and

local code requirements. Use copper wire only between

disconnect switch and unit. Use minimum 60 C wire for

field power connection.

Route power wires through opening in unit side panel

and connect in unit control box as shown on unit label

diagram and Fig. 6. Unit must be grounded