Fig. 9 — time guard ii sequence chart, Fig. 10 — wiring diagram, Maintenance – Carrier 38HD User Manual

Page 10: A caution, Lubrication

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Tl

T2

3

SEC

h

OPERATING

TIME

5MIN-

BLK DENOTES CLOSED CONTACTS

Fig. 9 — Time Guard II Sequence Chart

COMPRESSOR

LOCKOUT

Q

<1>-BLU-

(p d

l-BRN

BRN—(COMMON

TO THERMOSTAT

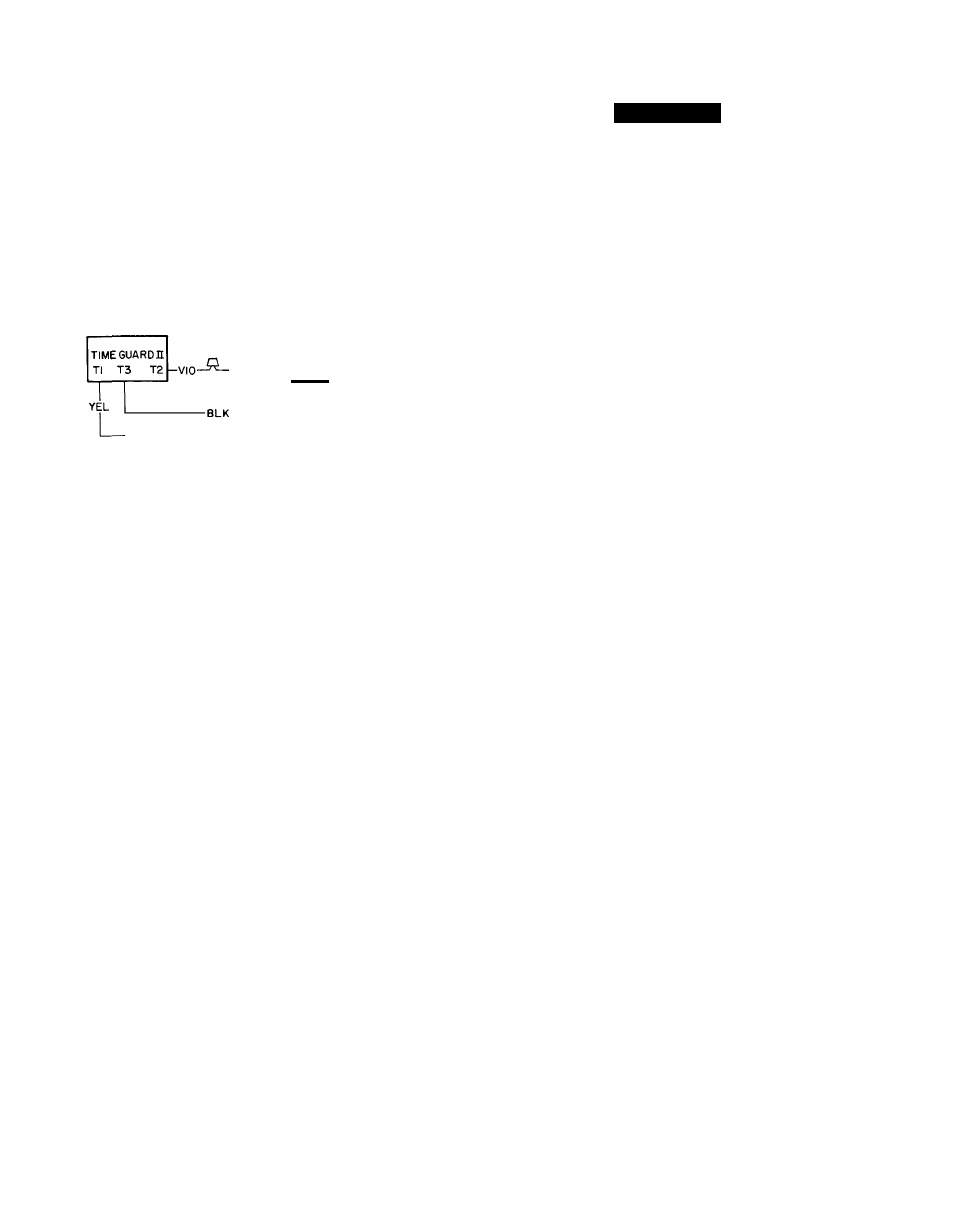

Fig. 10 — Wiring Diagram

See Fig. 10. Wire the device in series between the

compressor lockout (CLO) and the unit thermostat as

shown on unit wiring diagram.

Remove the wire from terminal 2 on the compressor

lockout and connect the violet wire from T2 on the Time

Guard 11 device to terminal 2 on the compressor lockout.

Connect the wire removed from terminal 2 on the com

pressor lockout to yellow wire T1 on the Time Guard 11

device. Connect black wire T3 on Time Guard 11 device

to common.

Compressor Lockout — Units with compressor

lockout protective device shut down on any safety trip.

Determine reason for safety trip. To restart, turn the

thermostat to OFF and then to COOL.

MAINTENANCE

A

CAUTION

Before performing recommended maintenance, be

sure unit main power switch is turned off. Failure to

do so may result in electric shock or injury from

rotating fan blade.

Lubrication

COMPRESSOR contains factory oil charge. Replace oil

when lost. See Table 2 for oil recharge and refer to

Carrier Standard Service Techniques Manual, Chapter 1,

page 1-21, for oil recharging procedure. Use Carrier

PP33-1, Texaco WF-32 or Suniso 3GS oil.

FAN MOTOR BEARINGS — Oiling holes are provided

at each end of condenser fan motor. Remove fan motor

and lubricate motor with 32 drops ( 16 drops per hole) of

SAE-10 nondetergent oil at intervals described below:

a.

Annually, when environment is very dirty, ambient

temperature is higher than 105 F and average unit

operating time exceeds 15 hours a day

b. Every 3 years when environment is reasonably clean,

ambient temperature is less than 105 F and unit

operating time averages 8 to 15 hours a day.

c.

Every 5 years when environment is clean, ambient

temperature is less than 105 F and unit operating time

averages less than 8 hours a day.

Cleaning Coils — Coils should be washed out with

water, or blown out with compressed air. The blow-thru

design causes dirt and debris to build up on the inside of

the coils.

Clean coil annually or as required by location or

outdoor air conditions. Inspect coil monthly, and clean as

required. Fins are not continuous through coil sections.

Dirt and debris may pass through first section, become

trapped between the row of fins and restrict condenser

airflow. Use a flashlight to determine if dirt or debris has

collected between coil sections. Clean coil as follows:

1. Turn off unit power.

2. U sing a water hose, or other suitable equipment, flush

coil from the outside to remove dirt Be sure to flush

all dirt and debris from drain holes in base of unit.

Fan motors are waterproof.

f

10