Step 2 — rig and mount unit, A caution, Caution – Carrier 38HD User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

RETAINER

FLARE NUT

Table 1 — AccuRater Optimization Chart

FLARE

CONNECTION

TYPE A

(Arrow on AccuRater body points in

metering

direction.)

(Arrow on AccuRater body points in

free flow

direction.)

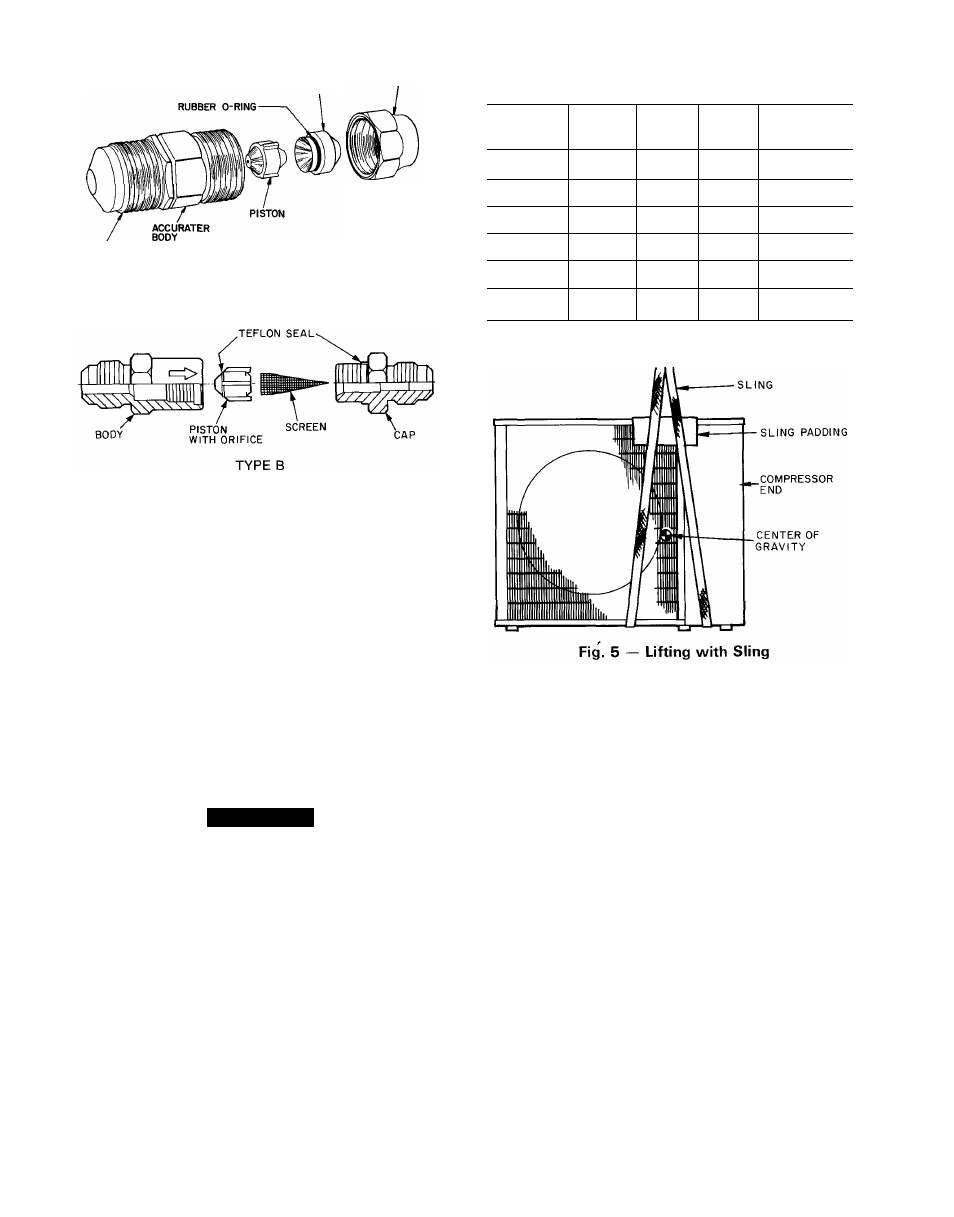

Fig. 4 — AccuRater® (Bypass Type) Components

Step 2 — Rig and Mount Unit

MOUNTING ON GROUND — Mount on a solid, level,

concrete pad Position unit so water or ice from roof

cannot drop directly onto unit. Stacking Kit 38H D900031

and -041 are available where such application is required.

See instructions provided with accessory kit. If conditions

or local codes require unit be fastened to pad, tiedown

bolts should be used and fastened through slots provided

in unit mounting feet.

MOUNTING ON ROOF

or frame.

Mount on a level platform

RIGGING

A

CAUTION

Be sure unit panels are securely in place prior to

rigging.

Keep unit upright. Lift unit using sling. Use cardboard

or padding under sling, and spreader bars to prevent sling

damage to unit. See Fig. 5. See Fig. 2 and 3 for center of

gravity reference. Install unit so that coil does not face

into prevailing winds. If this cannot be done, and constant

winds above 25 mph are expected, use Accessory Wind

Baffle, Part Number 38QR900041 or -051. See instruc

tions provided with accessory kit

Step 3 — Complete Refrigerant Piping Con

nections — Condensing units may be connected to

evaporator sections using field-supplied tubing of refrig

erant grade, correct size and condition. See Table 2.

Do not use less than 10 ft of interconnecting tubing and

do not bury more than 3 ft of line set undergrouiid. If any

section is buried, there must be a 6-in. vertical rise to the

valve connections on the outdoor unit

OUTDOOR

UNIT

INDOOR

UNIT

INDOOR

PISTON

PISTON

TYPE

REQUIRED

SYSTEM

CHARGE (lb)

38HD018

28RD024

40HD024

_

A

B

—

38HD024

28RD030

40HD024

61

A

B

55

38HD030

28RD043

40HD036

70

A

B

5 7

38HD036

28RD043

40HD036

73

A

B

11.5

38HD048

28RD049

40HD048

86

A

B

97

38HD060

28RD061

40HD060

88

A

B

11 2

If more than the recommended length is buried, refrig

erant may migrate to cooler buried section during

extended periods of unit shutdown. This causes refrig

erant slugging and possibly compressor damage at

start-up.

When more than 50 ft of interconnecting tubing and

more than 30 ft vertical lift is used, consider the amount of

liquid lift, and compressor oil return See Part 3 of Carrier

System Design Manual for design details, or contact your

local Distributor

If either refrigerant tubing or indoor coil is exposed to

atmospheric conditions for longer than 5 minutes, it must

be evacuated to 1000 microns to eliminate contamination

and moisture in the system.

Run refrigerant tubes as directly as possible, avoiding

unnecessary turns and bends. Suspend refrigerant tubes

so they do not damage insulation on vapor tube and do

not transmit vibration to structure Also, when passing

refrigerant tubes through wall, seal opening, so vibration

is not transmitted to structure. Leave some slack in refrig

erant tubes between structure and unit to absorb vibra

tion Refer to evaporator installation instructions for

additional information.

USE

FILTER

DRIER

AND

MOISTURE

INDI

CATOR — The filter drier is factory supplied. Moisture

indicator (sight glass) is a field-supplied option and