100 x – Carrier 38AK024-044 User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

4. Maximum field wire sizes allowed by lugs on terminal

block are:

350 MCM for models 38AK028 (208/230-3-60),

38AK034 (208/230-3-60, 230-3-50), and

38AK044 (208/230-3-60, 230-3-50)

2/0 AWG for all other models.

5. Terminals for field power supply are suitable for

copper, copper-clad aluminum or aluminum conduc

tors. Insulation must be rated 167 F (75 C) minimum.

CONDENSER FANS — The fans must rotate counter

clockwise when viewed from above. If necessary, correct

direction of fan rotation by interchanging any 2 power

input wires at disconnect switch. Affix crankcase heater

decal (located in installer’s packet) to unit disconnect switch.

FIELD CONNECTIONS

1. Main Power — Bring wires from the fused disconnect

switch through hole in bottom rail of unit to control

box (Fig. 6, 7, 8) and connect terminals 1 1 1 1 ,

[12

1 3 on line side of terminal block TBl (see Fig. 9).

To comply with NEC Article 440-14, the disconnect

must be located within sight from and readily acces

sible from unit.

■ 2. 24-v Control Power — Units have single point power

connections. Control circuit is directly connected inter

nally to unit. Maximum 24-v control circuit is 3 amps.

NOTE: For wire runs up to 50 ft. use no. 18 AWG

insulated wire (35 C min.). For 50 to 75 ft., use no. 16

AWG insulated wire (35 C min.). For over 75 ft. use 14

AWG insulated wire (35 C min.).

3. Control Circuit Interlock — An airflow switch may be

installed in the indoor air handler to prevent unit from

running when indoor air is not flowing. This switch (no.

HR81JE001) is available from Service Parts Center, or

equivalent can be field supplied. This should be electri

cally interlocked in the control circuit, between term

inals I 1 I and I 6 I (for flow switch) on TB2. See Fig.

9 for field wiring. This is in the 115-v circuit. Wires must

be run in conduit with ground wire.

4. Transformer Connections — See unit wiring label dia

gram, notes 1 and 2, located behind compressor com

partment end access door.

IMPORTANT: Ensure power to the crankcase

heater is always on (except when servicing the unit).

If circuit breakers inside unit shut down the com

pressor and condenser fans, crankcase heater

remains on.

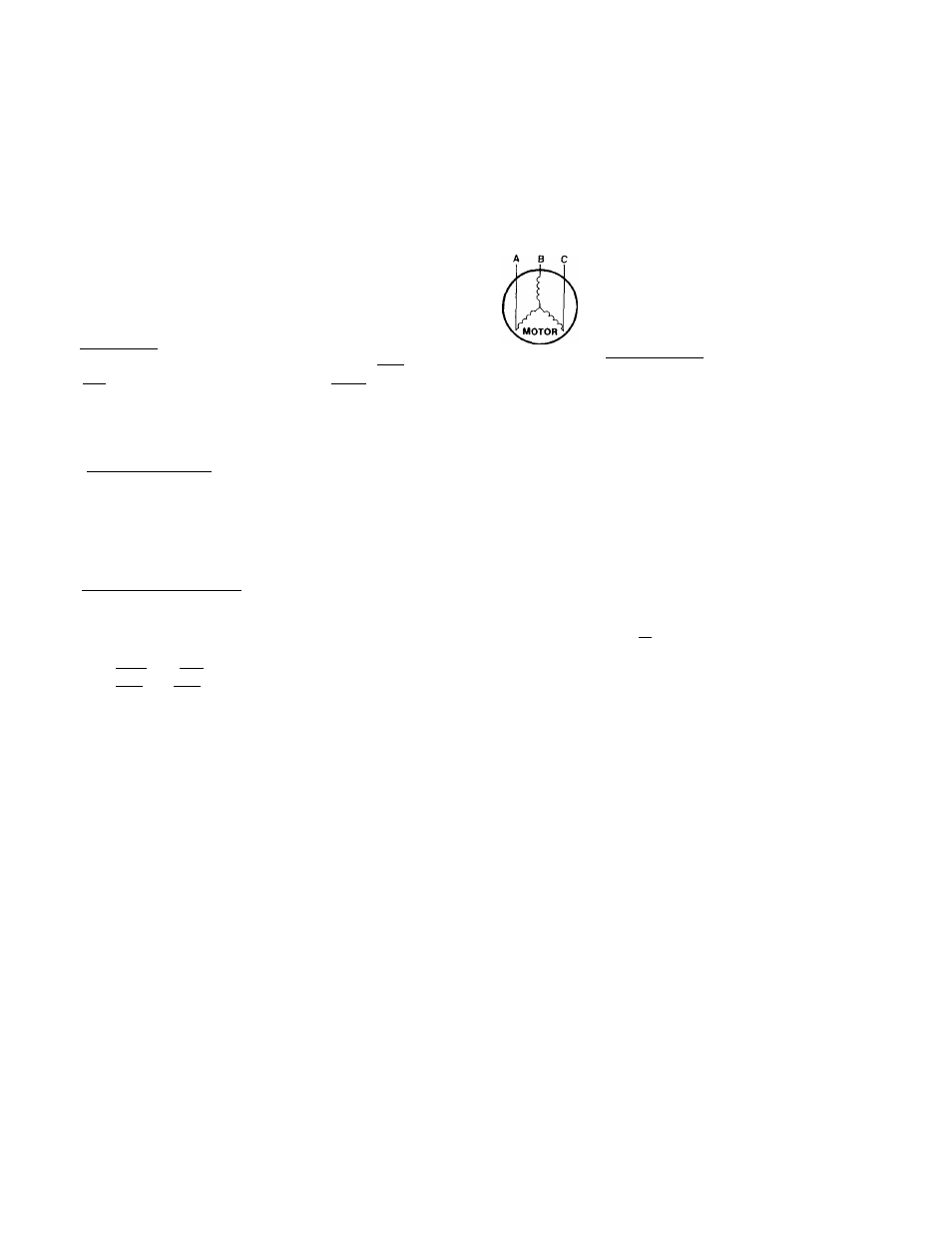

UNBALANCED 3-PHASE SUPPLY VOLTAGE —

Never operate a motor where a phase imbalance in supply

voltage is greater than

2%.

Use the following formula to

determine the

%

voltage imbalance:

% Voltage Imbalance

max voltage deviation from average voltage

I ^

= 100 X

average voltage

Example: Supply voltage is 240-3-60.

AB = 243 volts

BC = 236 volts

AC = 238 volts

Average Voltage =

243 + 236 + 238 = 239 volts

Determine maximum deviation from average voltage:

(AB) 243 - 239 = 4 volts

(BC) 239 - 236 = 3 volts

(AC) 239 - 238 = 1 volt

Maximum deviation is 4 volts. Determine

%

voltage

imbalance:

% Voltage Imbalance = 100 x —^ = 1.7%

239

This amount of phase imbalance is satisfactory as it is

below the maximum allowable 2%.

IMPORTANT: Contact your local electric utility

company immediately if the supply voltage phase

imbalance is more than 2%.