Carrier 38AK024-044 User Manual

Page 21

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Fan Adjustment (See Fig. 16)

TOP OF FAN ORIFICE

FILL HOLE IN FAN HUB

WITH PERMAGUM

FAN BLADE

ORIFICE

FAN SHAFT

HUB PLATE

PROP LOCATION

“A” in (mm)

Min.

Max.

60 Hz

36AK024

3

.

12

(

79

.

2

)

3.38 (85.9)

38AK028-034

38AK044

3.62(91.9)

3.88 (98.6)

50 Hz

38AK024

38AK028,034,044

3.62(91.9)

3.12(79.2)

3.88 (98.6)

338(85.9)

Fig. 16 — Location of Prop on Motor Shaft

from Outside of Orifice Ring

Oil Charge — Compressors are factory charged with oil

as follows:

COMPRESSOR

AMOUNT

pints (liters)

06E4250

14(6.6)

06E9265

19(9.0)

06E9275

19(9.0)

06E9299

19(9.0)

When additional oil or a complete charge is required, use

only Carrier-approved compressor oil:

Witco Chemical Corp....................................... Suniso 3GS

Texaco, Inc................................................... Capella WF-32

Shrieve Chemical Co..........................Zerol 150 (Synthetic)

IMPORTANT: Do not use drained oil or use oil that

has been exposed to atmosphere. Refer to Carrier

Standard Service Techniques Manual, Chapter 1,

Refrigerants, for procedures to add or remove oil.

Liquid Shutoff/Charging Valve is located inside the

compressor compartment and is provided with 1/4-in. flare

connection for field charging.

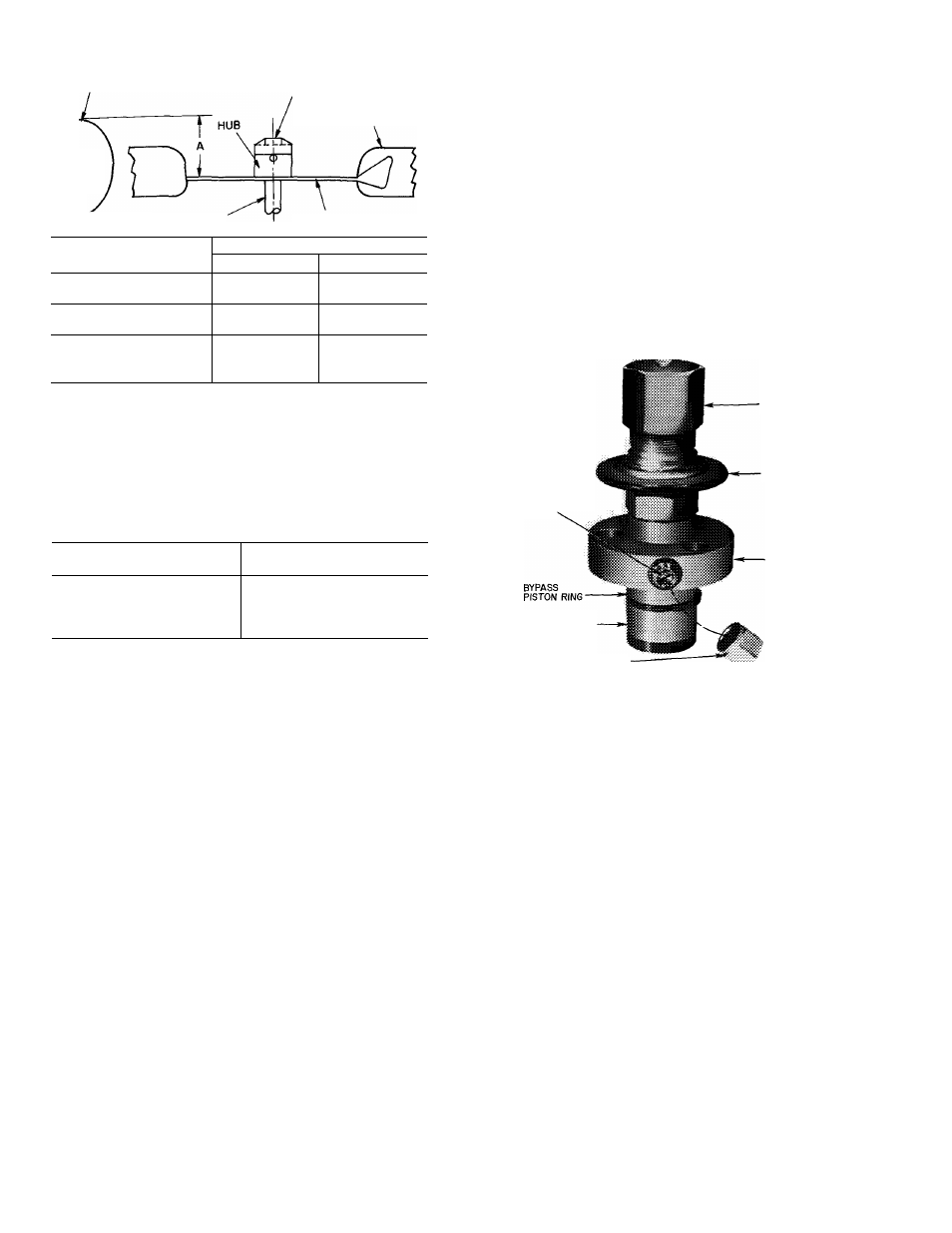

Capacity Control is by either one or 2 suction pressure

actuated unloaders. Each controls 2 cylinders. Unloaders

are factory set (see Table 1) but may be field adjusted.

Number 1 unloader is on cylinder bank on same side of

compressor as terminal box.

CONTROL SET POINT — The control set point (cylinder

load point) is adjustable from 0 to 85 psig. To adjust, turn

control set point adjustment nut (Fig. 17) clockwise to its

bottom stop. In this position, set point is 85 psig. Then, turn

adjustment counterclockwise to desired control set point.

Every full turn counterclockwise decreases set point by 7.5

psig.

CONTROL

SET POINT

ADJUSTMENT

NUT

PRESSURE

DIFFERENTIAL

ADJUSTMENT

SCREW

POWER HEAD

VALVE BODY

BYPASS PISTON

DIFFERENTIAL SCREW -

SEALING CAP

(CAP MUST BE REPLACED

TO PREVENT REFRIGERANT LEAKAGE)

Fig. 17 — Capacity Control Valve

PRESSURE DIFFERENTIAL—The pressure differenti^

(difference between cylinder load and unload points) is

adjustable from 6 to 22 psig. To adjust, turn pressure

differential adjustment screw (Fig. 17) counterclockwise to

its backstop position. In this position, differential is 6 psig.

Then, turn adjustment clockwise to desired pressure differ

ential. Every full turn clockwise increases differential by 1.5

psig.

18