Carrier 38AK024-044 User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

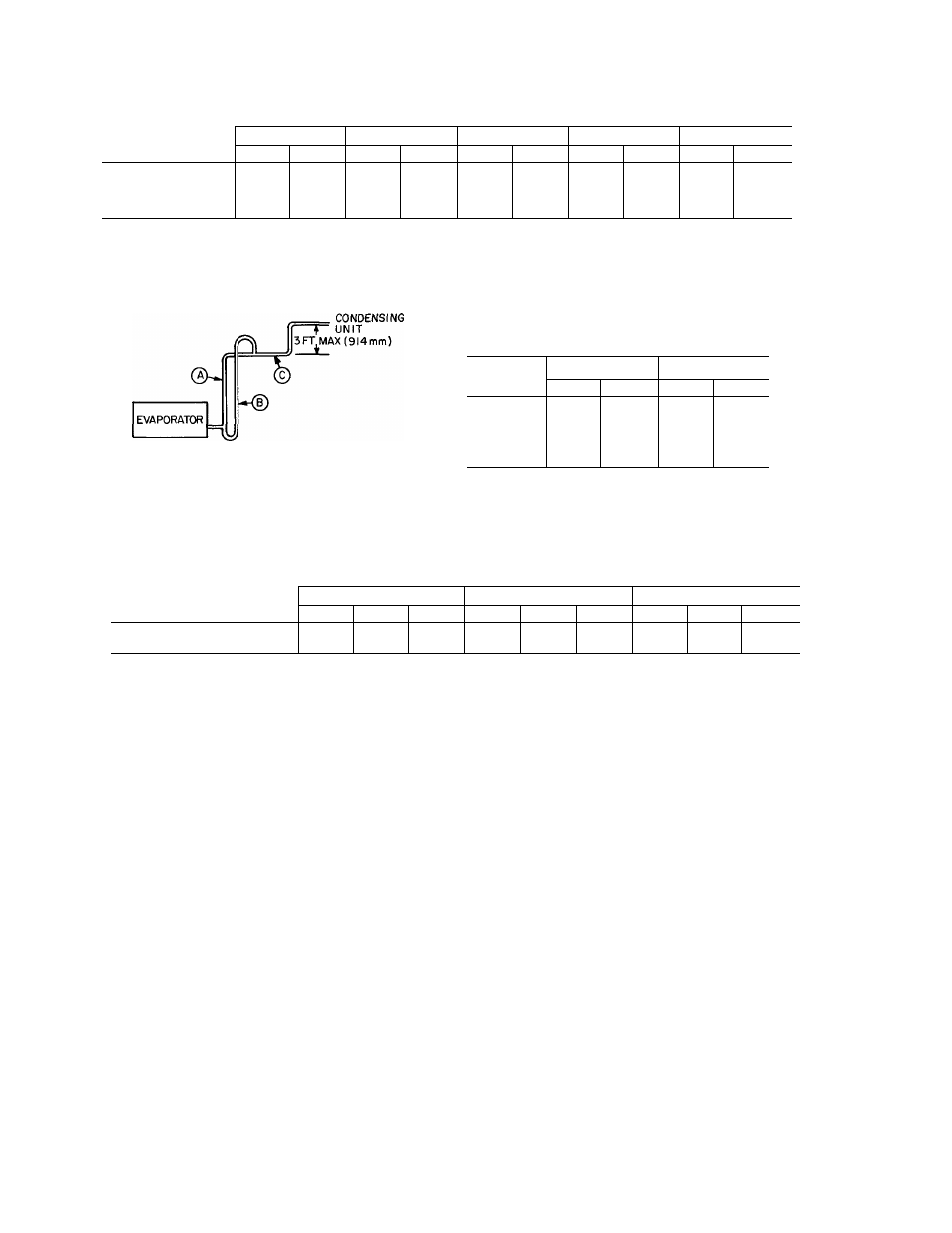

Table 2 — Refrigerant Piping Sizes

SINGLE SUCTION RISERS

LENGTH OF INTERCONNECTING PIPING (FT)

MODEL

38AK

16-25

26-50

51-75

76-100

101-200

L

S

L

S

L

S

L

S

L

S

024

5/8

1-5/8

7/8

1-5/8

7/8

2-1/8

7/8

2-1/8

7/8

2-1/8

028

7/8

1-5/8

7/8

2-1 /8

7/8

2-1/8

7/8

2-1/8

7/8

2-1/8

034

7/8

2-1 /8

7/8

2-1/8

7/8

2-1/8

1-1 /8

*

1-1/8

*

044

7/8

2-1/8

7/8

2-1/8

1-1/8

*

1-1/8

*

1-1/8

*

L-Liquid Line

S-Suction Line

* IMPORTANT

— Requires a double suction riser, see below:

NOTE: Liquid and suction iine sizes are OD (in)

(

a

) - SUCTION RISER WITHOUT TRAP

(

b

) - SUCTION RISER WITH TRAP

(^- SUCTION LINE TO CONDENSING UNIT

MAXIMUM LIQUID LIFT

UNIT 38AK

60 Hz

50 Hz

Ft

M

Ft

M

024

86

26

72

21

028

76

23

66

20

034

67

20

60

18

044

76

23

66

20

DOUBLE SUCTION RISERS

LENGTH OF INTERCONNECTING PIPING (FT)

MODEL

51-75

76-100

101-200

38AK

A

B

C

A

B

C

A

B

C

034

044

2-1/8

1-5/8

2-5/8

1-5/8

1-5/8

2-1/8

2-1/8

2-5/8

2-5/8

1-5/8

1-5/8

2-1/8

2-1/8

2-5/8

2-5/8

NOTE: A, B, C dimensions relate to reference diagram

SUCTION PIPING AT EVAPORATOR AND TXV

BULB LOCATION (See Fig. 5)

The purpose of these recommendations is to achieve good

mixing of the refrigerant leaving the evaporator suction

header for proper sensing by the TXV bulb.

1. A minimum of two 90° elbows must be installed

upstream of the expansion valve bulb location.

2. The TXV sensing bulb should be located on a vertical

riser where possible. If a horizontal location is neces

sary, secure the bulb at approximately the 4 o’clock

position.

3. Size the suction line from the evaporator through the

riser for high velocity. Enter the suction pipe sizing charts

in the Carrier System Design Manual at design tons and

equivalent length (for 2 degree F loss). If reading falls

between 2 sizes on chart, choose the smaller pipe size.

Suction piping for the high velocity section should be

selected for about 0.5 degree F friction loss. If a 2 degree

F loss is allowed for the entire suction line, 1.5 degree F

is left for the balance of the suction line and it should be

sized on that basis. Check that the high-velocity sizing is

adequate for oil return up the riser.

If an oil return connection at the bottom of this

suction header is supplied with an evaporator, this

connection must be teed-in ahead of first mixing elbow.

When the compressor is below the evaporator, the riser

at the evaporator does not have to extend as high as the

top level. After a 15-diameter riser has been provided,

the suction line may elbow down immediately.

SAFETY RELIEF — A fusible plug is located on unit

liquid line before the liquid valve.