Economizer section, A caution – Carrier 50DF034 User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CONDENSER

AND

COMPRESSOR

END

HORIZONTAL

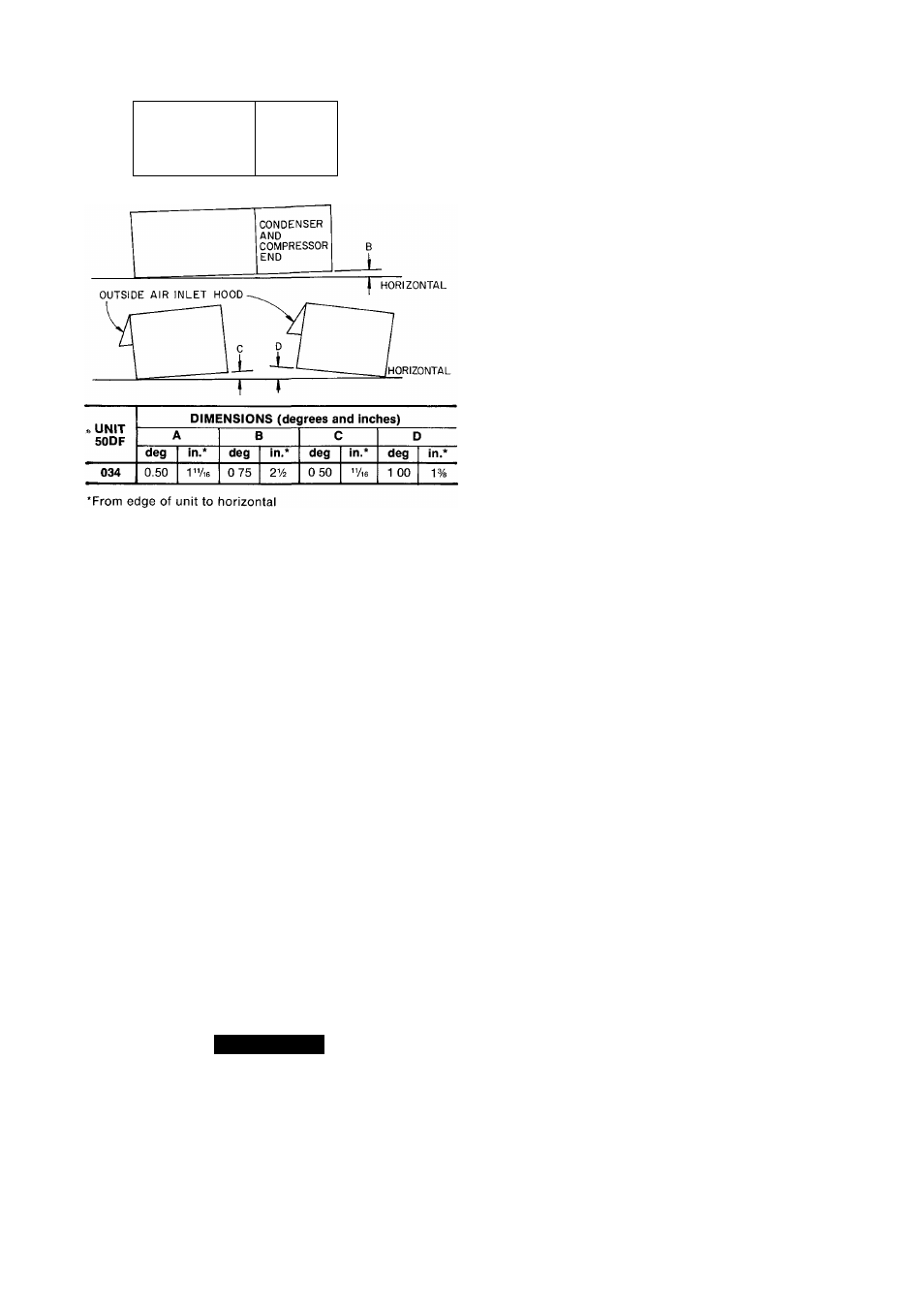

Fig. 3 — Unit Leveling Tolerances

Economizer Section

ECONOMIZER HOOD INSTALLATION (Fig. 7) —

The economizer mechanism and all electrical connections

are factory installed and adjusted except as noted below.

Hood assembly, outdoor air inlet screens and required

hardware are shipped separately and must be field

installed.

Install economizer hood and enthalpy control as

follows:

1. Loosen unit top panel sheet metal screws above out

door air inlet opening.

2. Assemble hood top panel, side panels and support

channel.

3. Insert hood flange between unit top panel flange and

unit. Slots are provided in hood flange to clear sheet

metal screws. Tighten sheet metal screws. To insure

water tightness, apply RTV to edges as indicated

by shaded portions of Fig. 7.

4. Secure hood side panels to outdoor air opening

flanges, using screws provided.

5. Install hood support bracket(s) between U-channel

and support channel.

6. Install screen retainer on support channel, using

screws in the slots. Do not tighten.

7.

A CAUTION

Shut off main power to unit before installing

enthalpy control assembly.

8. Remove enthalpy control assembly from shipping

location on horizontal deck in return air filter

compartment.

9. Using 4 no. 10-1/2 screws from envelope in control

assembly junction box, mount enthalpy control

assembly to inside of economizer hood side panel

nearest condenser section (Fig. 4).

10. Route the red and yellow wires through knockout

in side plate. Wrap end of blue wire with electrical

tape. Using wire connectors from envelope injunc

tion box, wire enthalpy control assembly as shown in

Fig. 8. Use strain reliefs from envelope on side plate

and junction box. Refer to Fig. 9 for Psychrometric

Chart for enthalpy control.

11. Install outdoor air screens.

12. Push retainer snugly against screens and tighten

screws.

Exhaust Air Hood Installation — The optional

power exhaust hood and damper assemblies and required

sheet metal screws are shipped in the compartment at

right of indoor air fan motor compartment. Using screws

provided, install a hood damper assembly over each

exhaust air opening as shown in Fig. 4. Power exhaust is

applied only to economizer units using bottom duct con

nections. Exhaust fan and motor assembly is factory

wired and adjusted. Refer to Service, Power Exhaust Air

Fan Adjustment if required.

Indoor Air Fans — The fan belt and pulleys are factory

installed and adjusted. If required, adjust as described

in Service, Indoor Air Fan Adjustment.

Condensate Drains — See Fig. 4 for drain locations.

Condensate drain is open to atmosphere and must be

trapped. Install a trapped drain line at connection to be

used. Trap must be at least 3 in. deep and made of flexible

material or be installed to prevent freeze-up.

Condensate drain pan under unit is fitted with a one-in.

FPT coupling. A gasket is shipped taped to this drain.

Install gasket in unit basepan opening or alternate open

ing on end of unit.

Field Power Supply — Unit is factory wired for

voltage shown on nameplate. The main power terminal

block is suitable for use with aluminum or copper wire.

See Fig. 10 and 11. Units have circuit breakers for

compressors, fan motors and control circuit. If required

by local codes, provide an additional disconnect switch.

If an external electrical source is used, unit must be

electrically grounded in accordanee with local codes, or

in the absence of local codes, with the National Electrical

Code, NFPA 70.

All field wiring must comply with National Electrical

Code and local requirements.

Install conduit connector in unit basepan or side panel

openings provided as shown in Fig. 4. Route power lines

through connector to terminal connections in control box

as shown in Fig. 10 and 11.

Affix crankcase heater sticker to unit disconnect

switch.

Voltage to compressor terminals during compressor

operation must be within voltage range indicated on unit

nameplate. Also, see Table 2. Phases must be balanced

within 2% Contact local power company for correction

of improper voltage or phase unbalance. Failure due to

operation of unit on improper line voltage or with exces

sive phase unbalance constitutes abuse and may cause

damage to unit electrical components.