Service, Electronic component checkout, A caution – Carrier 50DF034 User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

3. Remove spring on motor shaft.

4. Adjust switch as shown in Fig. 17.

5. After adjustment, replace spring on motor shaft and

reassemble return spring housing.

CAPACITY CONTROL, HEATING — Stages 1 and 2

of heaters are controlled by heating relays H R1 and H R2,

respectively. Using a suitable ammeter, check heater

current draw for heating assemblies or elements. When

checking second-stage heater operation, be sure heating

thermostat is set high enough to activate second-stage

heaters Also, check operation of outdoor air thermo

stats if additional staging is provided

TIME GUARD® CIRCUIT — Timer sequence for a

particular unit depends on unit and compressor arrange

ment. The Time Guard device provides a delay in com

pressor start-up after thermostat closes. On normal unit

start-up, outdoor air fans energize 15 seconds before the

compressor. If compressor/shutdown is due to satisfied

thermostat or automatic resetting of a safety device, the

compressor automatically restarts after a 5-minute

interval. If compressor shutdown is due to tripped over

loads, the circuit breakers must be manually reset before

compressor will start.

Timer (Time Guard) for second compressor has a 6-

minute interval to prevent compressors from starting

simultaneously.

Refer to unit label diagram for specific timer sequence.

CRANKCASE HEATER — Unit main power supply

must remain on to provide crankcase heater operation.

Crankcase heater in each compressor keeps oil free of

refrigerant while compressor is off.

HEAD PRESSURE CONTROL — Each unit has a fan

cycling thermostat to shut off outdoor fan motors at 55 F.

This permits unit to operate with correct condensing

temperatures down to 35 F outdoor air temperature.

SERVICE

Electronic Component Checkout

A CAUTION

Control circuit must be checked with system power

on. Disconnect power before checking wiring and use

care to avoid electrical shock and prevent equipment

damage.

____________________

The checkout procedures in this section will determine

whether-

1. The logic panel is controlling the heating and cooling

equipment properly.

2. System components are correctly wired to the logic

panel.

Prior to checking out control circuit, establish setting

on the low ambient lockout thermostat. Compressors

will not start below this setting (cooling mode only).

Recommended setting is approximately 50-55 F.

NOTE: To complete the electronic component checkout,

a volt-ohmmeter (Simpson 260 is recommended) is

required.

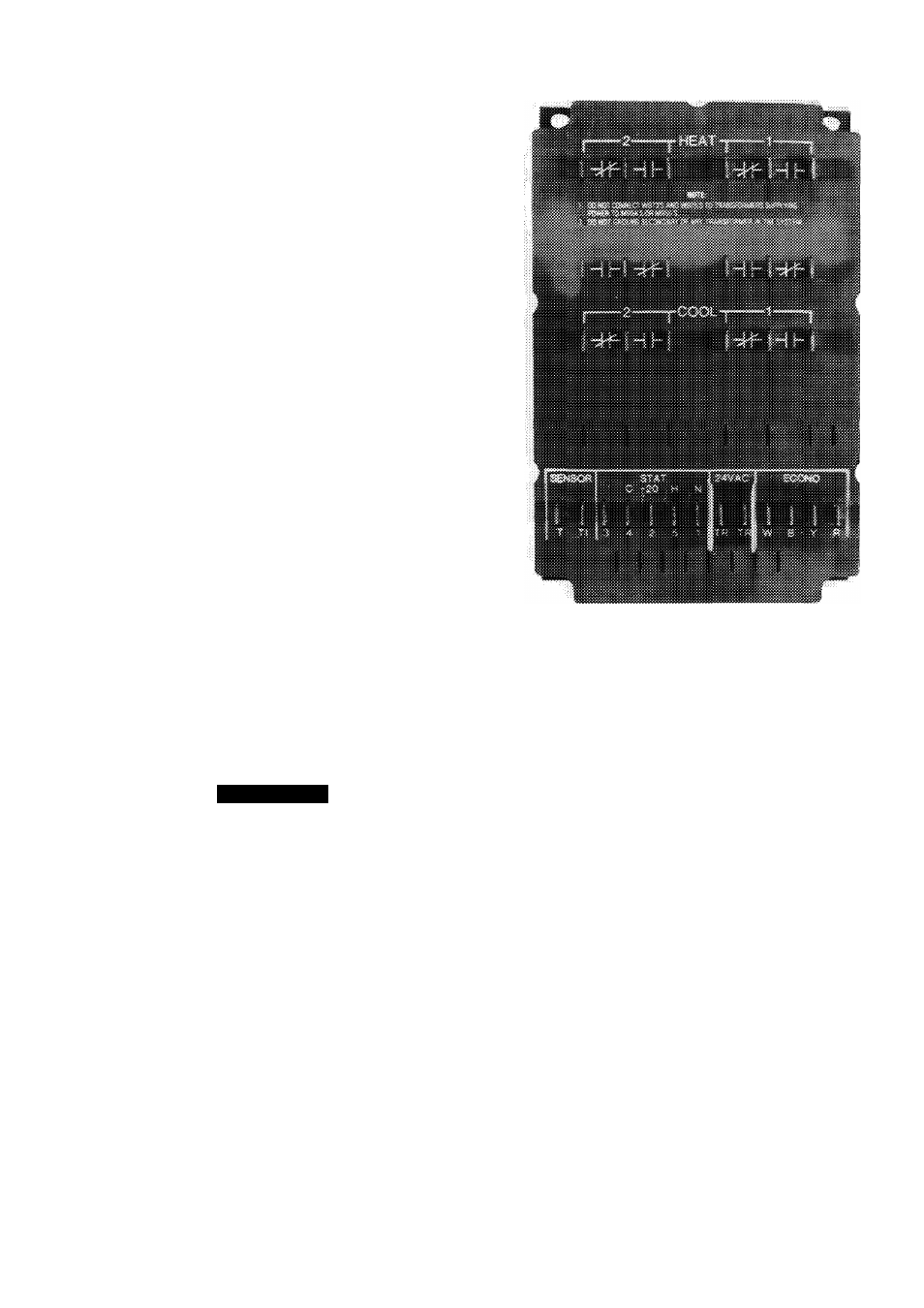

LOGIC PANEL (Fig. 18)

I. Check that 24 vac is supplied to logic panel Connect

meter to terminals TR.

2 Check thermostat supply voltage at STAT terminals

1 and 2. Reading should be 20 vdc.

Fig. 18 — Logic Panel (Standard Unit)

3 Remove thermostat supply wires from ST AT ter

minals 1 through 5 on logic panel.

4. Set meter to volts ac scale equal to relay switching

voltage (50-volt scale for 24 vac).

5. To simulate a call for cooling, jumper between STAT

terminals 2 and 4. Normally open logic panel contacts

(COOL 1 and 2) should close and cooling equipment

should cycle on.

6. Connect meter leads to the normally open cooling

contacts 1 and 2 on logic panel. Meter should read zero

if contacts have closed and contacts are made.

If meter is reading zero and cooling equipment has

not cycled on, logic panel is not at fault.

7. To simulate a call for heating, jumper between ST AT

terminals 2 and 5. Normally open logic panel contacts

(HEAT 1 and 2) should close and heating equipment

should cycle on.

8. Connect meter leads to the normally open heating

contacts on logic panel. Meter should read zero if

contacts have closed.

If meter is reading zero and heating equipment has

not cycled on, logic panel is not at fault.

9. Replace thermostat wiring to terminals 1 through 5.

DISCHARGE SENSOR

1 Set resistance on meter to R x 100.

2. Disconnect lead from SENSOR terminal T1 on logic

panel.

13