Table x—trouble analysis chart – Carrier 38GP User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

2.

3.

Check fan motor and blade for cleanliness and lubrica

tion each cooling season. Clean and lubricate as

necessary.

Check electrical connections for tightness and controls

for proper operation each cooling season. Service as

necessary.

A. Condenser Coil

Remember to disconnect electrical power before removing

any panels.

Since the air is drawn into the sides of the unit and dis

charged out the top, most of the dirt will collect on the out

side surface of the coil. However, some dirt will penetrate

the coil. This condition is very difficult to see without

removing the top cover.

To properly check the condenser coil for cleanliness, or to

clean the coil; proceed as follows:

1. Remove top cover. Enough motor wire is provided so

that the top cover can be lend on edge without discon

necting the motor leads. (CHp wire tie to release wire.)

2. Clean coil by spraying from inside outward with high-

velocity stream of water. (Garden hose is sufficient.)

Be careful not to damage the coil fins. Be sure to wash the

dirt from the coil. Space has been provided under the coil to

flush away the dirt. Drain holes are also provided in the

base pan. Be sure they are open. If the coil is coated with oil

or grease, it can be cleaned with a mUd detergent or an ap

proved coil cleaning agent, then rinsed with clear water. Be

careful not to get water in the compressor and unit control

boxes.

B. Condenser Fan Motor and Blade

Remember to disconnect electrical power before removing

any panels.

1. Remove screws holding top cover.

2. Lift top with motor and fan blade out of hole. Do not

cut or stretch motor electrical leads. Be careful not to

bend fan blade.

3. Clean motor and blade with soft brush or rag. Be care

ful not to disturb balance weights on fan blade.

4. Check fan blade setscrew for tightness.

5. Lubricate fan motor.

a. Remove dust caps or plugs from oil holes located at

each end of motor.

b. Use teaspoon, 5cc, 3/16 oz, or 16 to 25 drops of good

grade SAE 20 nondetergent motor oil in each hole.

AUow time for total quantity to be absorbed by each

bearing.

c. Wipe excess oil from motor housing.

d. Replace dust caps or plugs in oil holes.

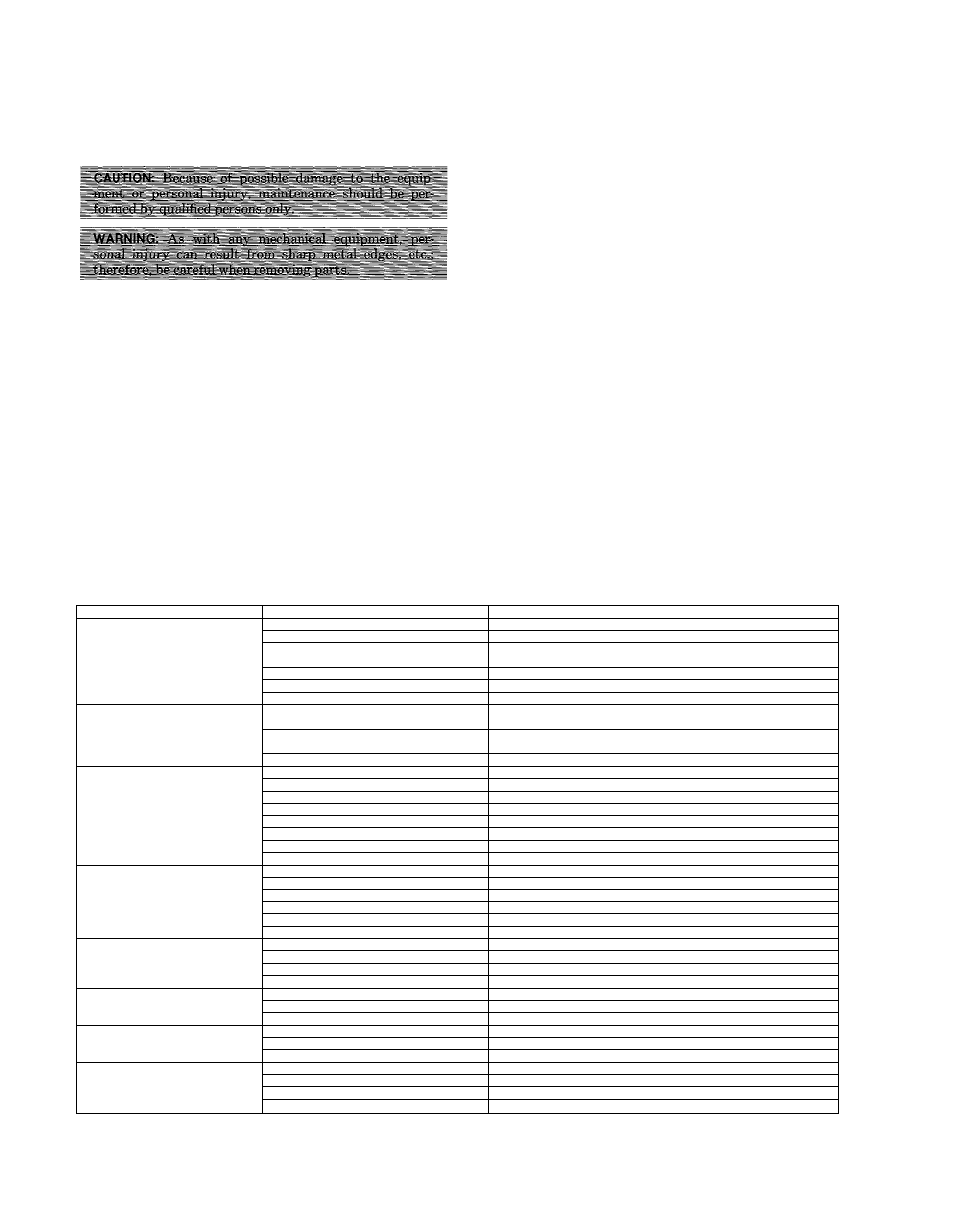

TABLE X—TROUBLE ANALYSIS CHART

SYMPTOM

CAUSE

REMEDY

Compressor and condenser

fan will not start

Power failure

Call power company.

Fuse blown or circuit breaker tripped

Replace fuse or reset circuit breaker.

Defective thermostat, contactor,

or control relay

Replace component.

Low line voltage

Determine cause and correct.

Incorrect or faulty wiring

Check wiring diagram and rewire correctly.

Thermostat setting too high

♦Lower thermostat setting below room temperature.

Compressor will not start,

but condenser fan runs.

Faulty wiring or loose connections in

compressor circuit

Check wiring and repair or replace.

Compressor motor burned out, seized, or

internal overload open

Replace compressor and determine cause.

Defective run capacitor

Determine cause and replace.

Compressor cycle (other than

normally satisfying thermostat).

Refrigerant over or under charged

Blow refrigerant, evacuate system, and recharge.

Defective compressor

Replace and determine cause.

Low line voltage

Determine cause and correct.

Blocked condenser

Determine cause and correct.

Defective run capacitor

Determine cause and replace.

Defective thermostat

Replace thermostat.

Faulty condenser fan motor or capacitor

Replace.

Restriction in refrigerant system

Locate restriction and remove.

Compressor operates

continuously.

Unit undersized for load

Decrease load or increase unit size.

Thermostat set too low

♦Reset thermostat.

Low refrigerant change

Locate leak; repair and recharge.

Leaking valves in compressor

Replace compressor.

Air in system

Blow refrigerant, evacuate system, and recharge.

Condenser coil dirty or restricted

Clean coil or remove restriction.

Excessive head pressure

Dirty condenser coil

Clean coil.

Refrigerant overcharged

Purge excess refrigerant.

Air in system

Blow refrigerant, evacuate system, and recharge.

Condenser air restricted or air short-cycling

Eliminate cause.

Head pressure too low

Low refrigerant charge

Check for leaks; repair and recharge.

Compressor valves leaking

Replace compressor.

Restriction in liquid tube

Remove restriction.

Excessive suction pressure

High heat load

Check for source and eliminate.

Compressor valves leaking

Replace compressor.

Refrigerant overcharged

Purge excess refrigerant.

Suction pressure too low

Low refrigerant charge

Check for leaks: repair and recharge.

Metering device or low side restricted

Remove source of restriction.

Low evaporator air

Increase air.

Temperature too low in conditioned area

♦Reset thermostat.

♦Thermostat should be set between 72° and78°F.

—6—