Service, Cailtiomi m iufeisjg or doroags tmy – Carrier 38EC User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Correct use of Chargemaster ensures that an opti

mum refrigerant charge will be in system when con

ditions

and

system

components

are

normal.

However, the Chargemaster does not solve or fix

system abnormalities. It indicates correct charge for

condition of the system. It will not make corrections

for dirty filters, slow fans, excessively long or short

suction lines or other abnormal conditions. This

charging device ensures that a correct relationship

exists between outdoor temperature, evaporator

temperature, and suction line temperature on a spe

cific system.

SIGHT GLASS METHOD — (Field-supplied sight

glass installed in liquid line.) A satisfactory oper

ating charge can be obtained on thermal expansion

valve systems only by charging to a clear sight glass.

For optimum charge, increase high-side pressure to

380 ± 10 psig by blocking condenser fan discharge

or air entering condenser. Charge to a clear sight

glass while holding constant high-side pressure. For

peak efficiency, adjust charge to yield a liquid refrig

erant temperature at the evaporator that is approxi

mately the same as outdoor dry-bulb temperature.

SERVICE

Compressor Removal

— See Table 8 for com

pressor information and Fig. 7 for component loca

tion. Shut off power to unit. Remove refrigerant

from unit using refrigerant removal methods de

scribed in Carrier Standard Service Techniques

Manual, Chapter 1, Refrigerants. Be sure system

pressure is 0 psig before attempting eompressor

removal.

^

Table 8 — Compressor Data

UNIT

PRODUCTION

OIL CHARGE (oz)t

38EC

COMPR*

Initial

Recharge

018300

AJ8520G

26

24

024300

CRD-0200PFV

55

51

030300

CRF1-0250PFV Ì;

55

51

036300

CRJ1-0300PFV

55

51

042310

AV5542E

54

50

048300

YRD-0400-PFV

72

68

048310

PC5016BD

66

62

060300

PC6416AG

66

62

030500

CRF1-0250-TF5

55

51

036500

CRJ1-0300-TF5

55

51

042510

AV5542E

54

50

048500

YRD6-0400-TFC

72

68

048510

PY5016BD

66

62

060500

PY6416AF

66

62

036600

CRJ1-0300-TFD

55

51

042610

AV5542E

54

50

048600

YRD6-0400-FFD

72

68

048610

PH5016BD

66

62

060600

PH6416AF

66

62

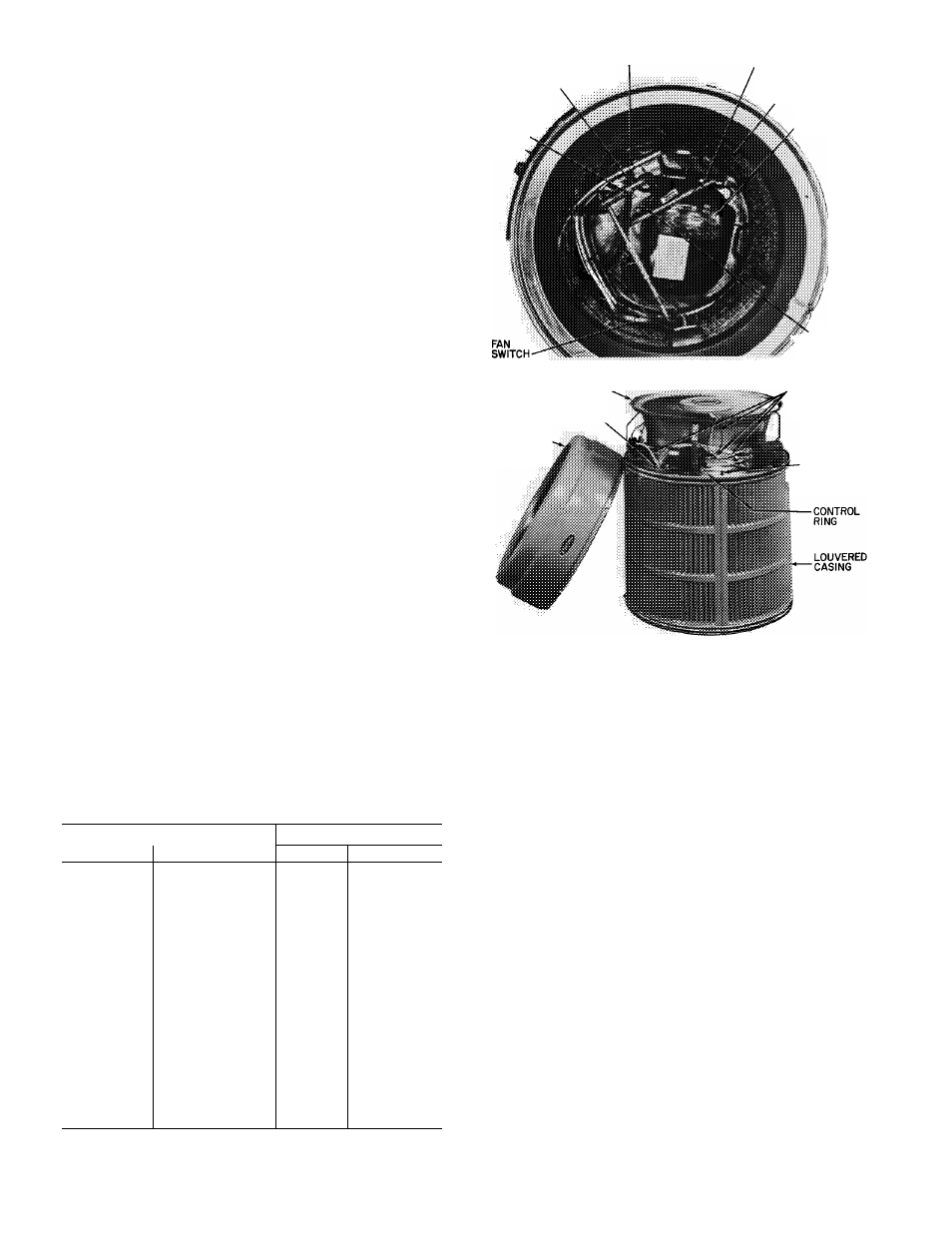

CRANKCASE HEATER SWITCH

SUCTION LINE

LOW

PRESSURE

SWITCH

HOT GAS

DISCHARGE LINE

CONDENSER COIL

COMPRESSOR

DISCHARGE GRILLE (FAN

MOTOR UNDERNEATH) ^

WIRE ACCESS OPENING

TOP COVER-

HIGH-

'/ PRESSURE

SWITCH

FAN MOTOR

AND

COMPRESSOR

LEADS

PLASTIC PIN

OF TUBE

lì SUPPORT

'Refer to Carrier Service Parts Catalog for replacement model

numbers

tWhere piping exceeds 50ft, obtain information from local Carrier

distributor

Fig. 7 — Condensing Unit 38EC

Component Locations

Follow safety codes. Wear safety glasses and

work gloves. Have quenching cloth available.

CAilTIOMi

m iufeisjg or doroags tmy

1. Remove top cover: remove 3 screws holding

top cover to connector plate; remove third screw

clockwise from connector plate; loosen remain

ing 5 screws; lift cover straight up.

2. Disconnect high- and low-voltage field wiring

and fan motor leads from capacitor and

contactor.

3. Remove 4 screws (38FC018 thru 030) or 8 screws

(38FC036 thru 060) holding discharge grille in

place. Lift grille from unit.

4. Disconnect compressor leads (crankcase heater,

low-pressure switch, if so equipped) from elec

trical components and pull them thru the wire

access opening into the coil section. Lift fan

orifice/control ring after pinching and pressing

down on 3 plastic pins of tube supports.

5. Remove louvered casing by taking out 16 screws

securing it to the cabinet and sliding it away

from the coil.