Start-up, Refrigerant charging – Carrier 38EC User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

START-UP

1. Backseat (open) liquid and suction line service

valves. Open liquid line first to equalize pres

sure and reduce oil flow to suction line.

2. Set thermostat selector switch at OFF.

3.

Set room thermostat at desired temperature.

Be sure this temperature is below indoor ambient.

4.

Close electrical disconnects energizing entire

system.

5. Set room thermostat at COOL and fan switch at

FAN or AUTO, as desired. Operate unit for 15

minutes; then check system refrigerant charge.

See Refrigerant Charging, discussed later.

Motors and controls are designed to operate satis

factorily in the voltage range shown in Table 4. If

necessary to use manifold gages for servicing, refer

to Carrier Standard Service Techniques Manual,

Chapter 1, Refrigerants, page 1-5, Fig. 8 for bypass

method of returning charge to system. Removal of

liquid line charging hose without following these

precautions could result in some loss of charge.

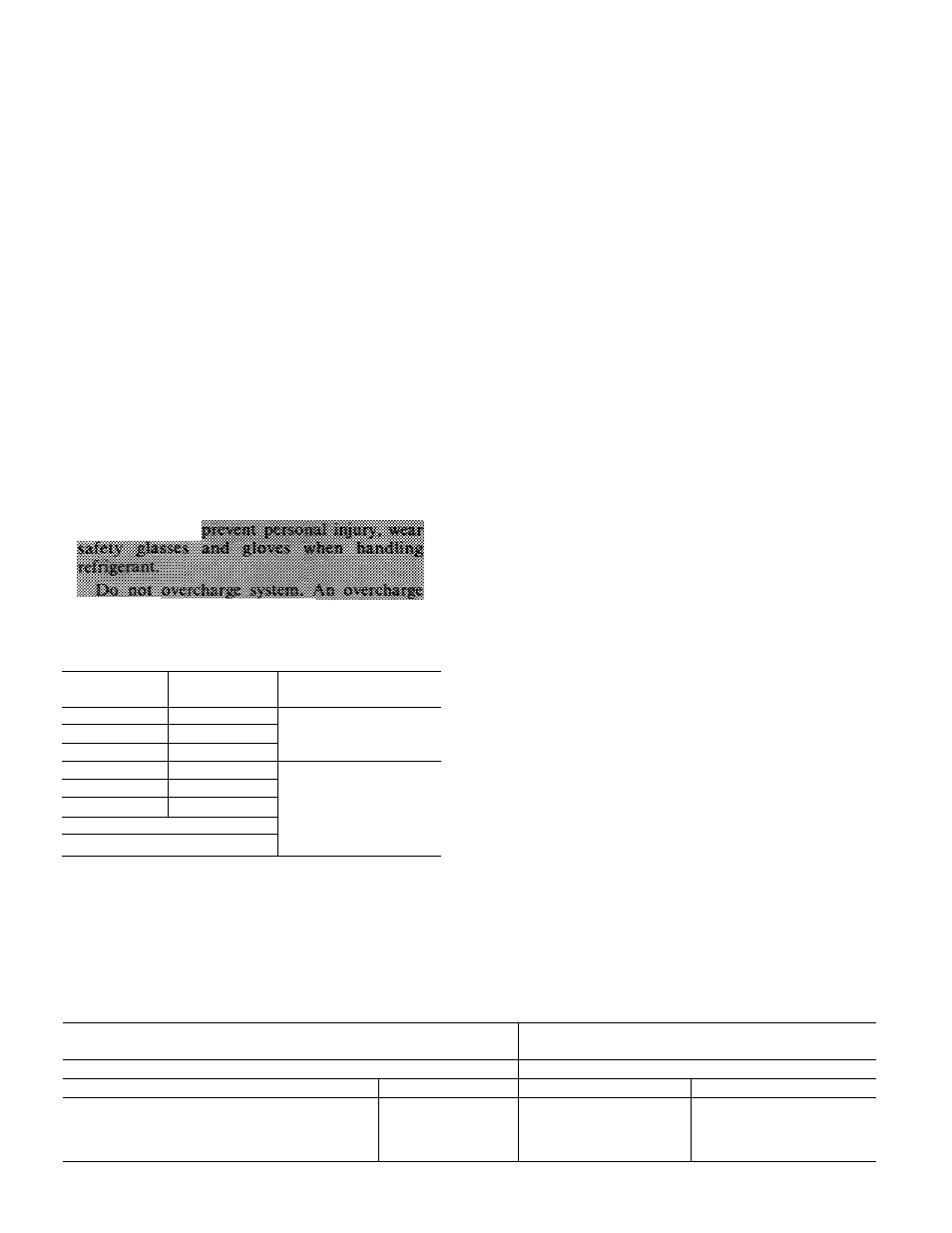

Refrigerant Charging

ca» саяш

flooding.

Table 5 — Service Data

UNIT

38EC

R-22 CHG*

(lb)

CONDENSER

FAN RPM (Hi/Lo)

018

3 3

024

3 3

1110/950

030

5 3

036

7.5

042

63

048300

6 1

1075/950

048310

72

060

9 6

‘Factory refrigerant charge is adequate when evaporator and con

densing unit are the same size and are connected with 25 ft or less

of field-supplied tubing of recommended size or Carrier accessory

tubing

Condensing

units

contain

correct

operating

charge for complete system when connected to

Carrier-approved evaporators of same capacity as

condensing unit with 25 ft or less of Carrier accessory

tubing or field-supplied tubing of recommended

size. For every 10 ft of liquid line of recommended

size over 25 ft, add refrigerant charge as follows: .41b

for 3/8-in. line; .28 lb for 5/ 16-in. line. On all other

systems, adjust eharge for correct operation as

applicable.

Service port eonnections are provided on liquid

and suction line service valves for evacuation and

charging. See Fig. 1.

TO CHECK, ADJUST OR REPLACE REFRIG

ERANT CHARGE use method recommended in

Table 6. Details of charging methods are listed

below.

Before recharging system, thoroughly evacuate

system and then weigh in refrigerant charge speci

fied in Table 5. Check or adjust charge as required.

Refer to Carrier Standard Service Techniques

Manual, Chapter 1, Refrigerants, for additional sys

tem evacuation and dehydration instructions.

WEIGHT METHOD — Refer to Table 5 or unit

nameplate for correct system refrigerant charge.

Remove any refrigerant remaining in system before

recharging.

When system is not evacuated, subtract the

following amount from total charge.

38EC018 thru 030 — .10 lb (1.6 oz)

38EC036 thru 060 — .20 lb (3.2 oz)

The Dial-a-charge charging cylinder is an accu

rate device used to recharge system by weight. These

cylinders are available at refrigeration supply firms.

CHARGING CHART METHOD — Use Charging

Chart, Fig. 6, and the following procedure.

1. Operate unit a minimum of 10 minutes before

checking charge.

Measure suction pressure by attaching a gage to

suction valve service port.

Measure suction line temperature by attaching a

service thermometer to unit suction line near suc

tion

valve.

Insulate

bulb,

thermocouple

or

thermistor for accurate reading.

2

.

3.

f:

Table 6 — Refrigerant Charging Methods

I

METHODS OF CHECKING OR

roNniilMlT ADJUSTING CHARGE

METHODS FOR COMPLETE

RECHARGING

38EC

1

System Refrigerant Control

System Refrigerant Control

1

Non TXV

TXV

Non TXV

TXV

1 Chargemaster®

ALL 1 or

1 Charging Chart

Sight

Glass*

Weight Method

plus

Chargemaster or

Charging Chart

Weight Method

plus

Sight Glass*

‘Sight glass field supplied and installed in liquid refrigerant line