Carrier 38EC User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Compatible Fitting Repair

MECHANICAL CONNECTION — Frontseat unit

service valves. Relieve refrigerant pressure from

tubing. Back off locknut from Compatible Fitting

onto tube. Cut fitting between threads and 0-ring

as shown in Fig. 8. Remove tubing section

remaining in threaded portion of fitting. Discard

locknut.

Clean, flux, and insert new tube end into remain

ing portion of Compatible Fitting. Wrap valve in

wet rag. Heat and apply low-temperature (430 F)

solder. Do not overheat valve.

Evacuate or purge evaporator coil and tubing

system. Add refrigerant charge. See Refrigerant

Charging instructions described previously.

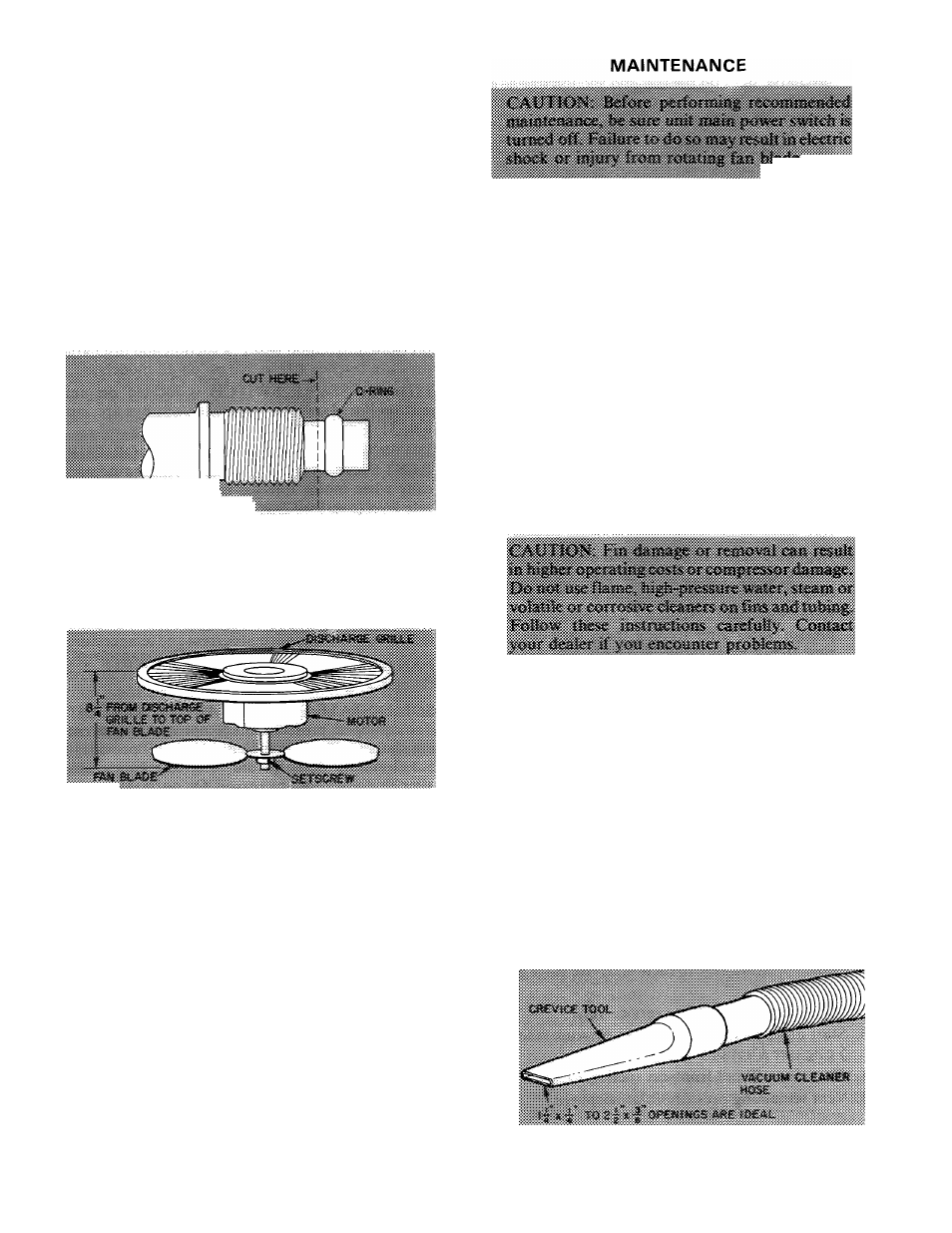

Fig. 8 — Repair of Mechanical Connection

Condenser Fan Adjustment

— Required fan

position is shown in Fig. 9. Adjust fan by loosening

setscrew(s) and moving fan blade up or down.

Fig. 9 — Condenser Fan Position

Condenser Fan Motor Removal

1. Shut off power to unit. Failure to do so may

result in electric shock or injury from rotating fan

blade.

2.

Remove top cover, referring to Compressor

Removal, step 1.

3. Disconnect fan motor leads from control leads.

See Fig. 7.

4. Remove 4 screws (38EC018 thru 030) or 8 screws

(38EC036 thru 060) holding fan motor/discharge

grille in place and lift assembly from unit.

5.

Remove Carrier nameplate by straightening

tabs.

6. Remove 4 nuts holding fan motor to discharge

grille. Remove motor and leads.

7. Reassembly is reverse of above procedure. Make

sure fan is positioned correctly as in Fig. 9.

Lubrication

■COMPRESSOR contains factory oil charge. Re

place oil when lost. See Table 8 for oil recharge and

refer to Carrier Standard Service Techniques

Manual, Chapter 1, page 1-21, for oil recharg

ing procedure. Use Carrier PP33-1, Texaco WFl-32

or Suniso 3GS oil.

FAN MOTOR BEARINGS are prelubricated for 3

years heavy duty or 5 years normal duty. When

lubrication is necessary, send motor to authorized

motor repair shop.

^Coil Repair

— A flare-union coupling repair kit

is available, with instructions, thru Carrier Service

Parts.

Coil Cleaning

to be done at the beginning of

each cooling season or more often if required.

1. Shut off power to unit.

2. Remove louvered casing by taking out 16 screws

securing it to the cabinet and sliding it away from

the coil.

3. Clean coil using vacuum cleaner and its crevice

tool (see Fig. 10). Work crevice tool vertically

making sure tool only touches dirt on fins. To

prevent fm removal, do not “scrub” fins with tool

or move tool horizontally.

4. If oil deposits are present, spray coil with house

hold detergent (Fantastic, Lestoil, 409, or any

similar type). Wait 10 minutes then proceed to

step 5.

Fig. 10 — Crevice Cleaning Tool

10