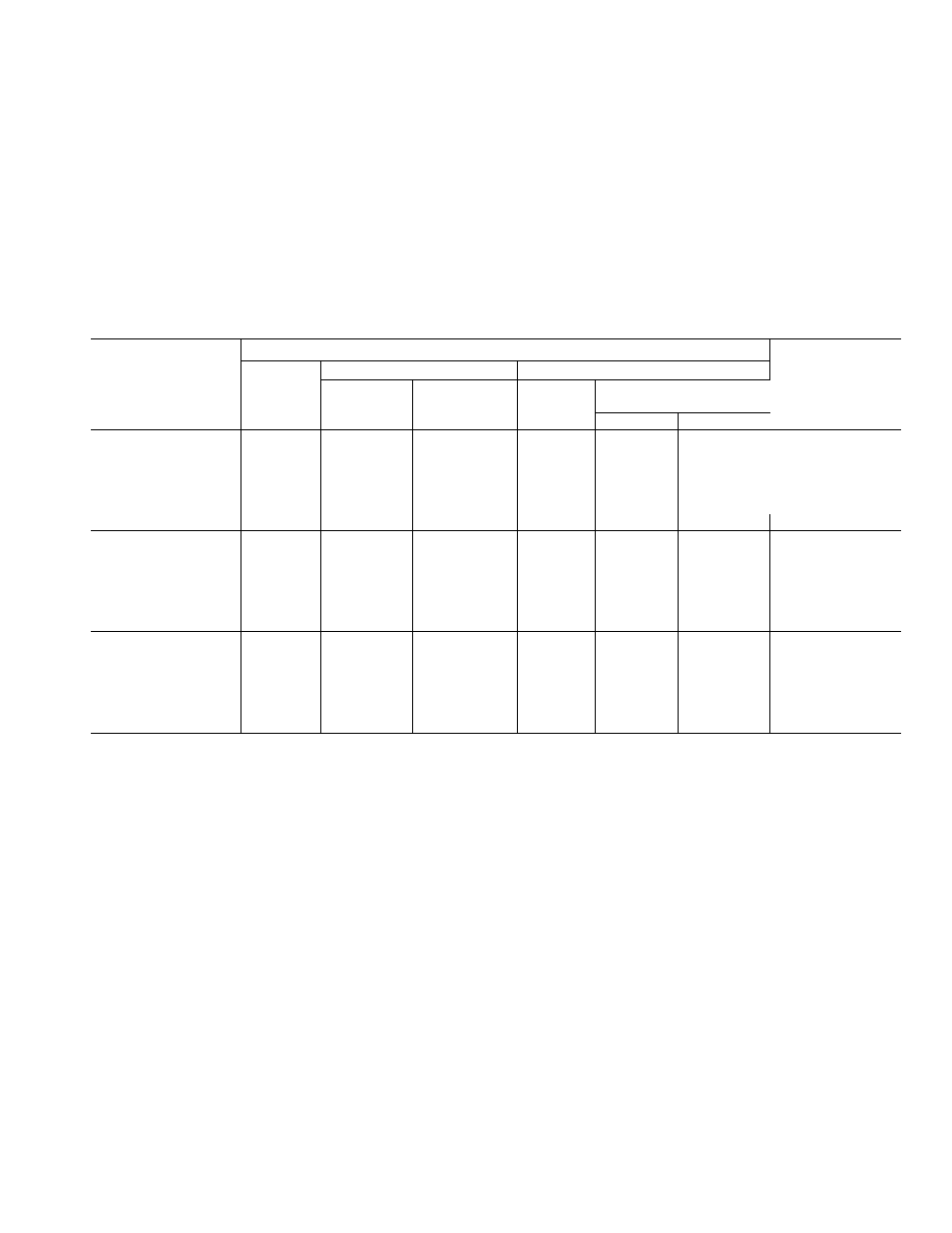

Table 3 — accessories – Carrier 38EC User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 3 — Accessories

PART NO

DESCRIPTION

MODEL

38EC

HH01AD040

HH93AZ040

Low-Voltage Control Honeywell Deluxe Thermostat

Thermostat Subbase

HH07AT170

&

HH07AT174

HH93AZ176

Low-Voltage Control

Honeywell Thermostat

Thermostat Subbase

HH01AD042

HH93AZ042

Low-Voltage

Control

Honeywell

Thermostat

Thermostat Subbase

All

HH01YA192

HH93YZ194

Low-Voltage

Control

Grayson

Thermostat

Thermostat Subbase

38GS900102

Indoor Fan Relay (Six HN61KJ210)

38GS900212

Low-Voltage Transformer (Six 38GS900091)

28VQ900011

Twelve 3/4- x 1-1/8 in Connection Adapters

048, 060

09WQ036.060

Refrigerant-to-Water Heat Exchanger for Chilled Water Systems

All

TUBING

PACKAGES

TUBING

*

MODEL

38EC

Length

(ft)

Liquid

Suctionf

OD

(in.)

Tube End

OD (in.)

OD

(in )

Tube End

OD (in.)

Evap

Cond

38LS958151

15

3/8

3/8

5/8

3/4t

5/8

38LS958201

20

3/8

3/8

5/8

3/4t

5/8

38LS958251

25

3/8

3/8

5/8

3/4t

5/8

38LS958301

30

5/16

3/8

5/8

3/4t

5/8

018, 024

38LS958351

35

5/16

3/8

5/8

3/4t

5/8

38LS958401

40

5/16

3/8

5/8

3/4t

5/8

38LS958501

50

1/4

3/8

5/8

3/4t

5/8

38LS934151

15

3/8

3/8

3/4

3/4

3/4

38LS934201

20

3/8

3/8

3/4

3/4

3/4

38LS934251

25

3/8

3/8

3/4

3/4

3/4

38LS934301

30

3/8

3/8

3/4

3/4

3/4

030, 036

38LS934351

35

3/8

3/8

3/4

3/4

3/4

38LS934401

40

3/8

3/8

3/4

3/4

3/4

38LS934501

50

3/8

3/8

3/4

3/4

3/4

38LS978151

15

3/8

3/8

7/8

3/4

3/4

38LS978201

20

3/8

3/8

7/8

3/4

3/4

38LS978251

25

3/8

3/8

7/8

3/4

3/4

38LS978301

30

3/8

3/8

7/8

3/4

3/4

38LS978351

35

3/8

3/8

7/8

3/4

3/4

38LS978401

40

3/8

3/8

7/8

3/4

3/4

38LS978501

50

3/8

3/8

7/8

3/4

3/4

‘For maximum capacities, use suction line sizes recommended in

Table 1 Use of accessory tubing packages smaller than recom

mended may result in slight capacity loss (see Note 2)

tSuction line is insulated and has a 90 degree bend at one end

JFor 5/8-in evaporator connection, cut off 3/4-in end

NOTES

1

Do not cut 3/8-in OD liquid lines to a length shorter than 10

feet Do not cut 5/1 6-or 1/4-in liquid line Do not cut 7/8-in

OD suction lines

2

Field-supplied

1-1/8

in

suction

line

is

recommended

on

38EC048 and 060 If accessory tubing package is used, a

capacity reduction can result

■ WAHNiKO' IK> HOI Et'RY LiNESETS. if

is

for exsojaSod peraaisi. dint

ing vmtn westiher. rdVigoraoi may

to

the cookr boiieii ssetioo catismg

sltsggisig m

A sksn ruo of kss

3 Ci of Uoesei may in pousni but ihore mmi fee

a 6 m vetiicai rise lo ifee valve cotmociiona oo

tire condeosiog sale.

Isolate interconnecting tubing from framing and

ductwork or where tubing runs thru stud spaces, en

closed ceilings or pipe chases. Use isolation type

hanger (Fig. 3) since rigid fastening transmits pulsa

tions to structure, creating objectionable sound.

For maximum capacity on 38EC048 and 060 sys

tems use 1-1/8 in. suction line. A capacity reduction

results if Carrier accessory tubing is used on these

systems. (Example: When a 25-ft accessory tubing

package is used on a 38EC048 system, the smaller

suction line results in a 3% capacity reduction.)

Length of interconnecting tubing may necessitate

refrigerant charge adjustment. Follow special re

quirements

described

in

Start-Up,

Refrigerant

Charging, page 6. Do not use less than 10 ft of inter

connecting tubing. On Carrier accessory tubing

packages, do not cut 5/ 16-in. or 1/4-in. liquid line or

7/8-in. suction line. These tubing packages have

swaged ends that, if cut, will not fit into refrigerant

line fittings. Bend or coil excess tubing to fit.

Do not use damaged, undersized or contaminated

tubing. Always evacuate or purge evaporator coil

and tubing system. When purging, use field-supplied

refrigerant, not unit holding charge refrigerant.