Fig. 7 — component location, Caution: aíuíiwíusííj ititsing, Ir? uiüí – Carrier 380B User Manual

Page 9: Oil líífesííg of damage may result, Have ftm extiugaisfeef âïtdior qtjieucbifig, 1 ""tm, H m&á

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

6. From intersect point, project vertically down

ward to chart suction pressure line. Compare

chart suction pressure to unit suction pressure

(Step 2).

7. If unit suction pressure is lower than chart pres

sure, add refrigerant to system until chart

pressure is reached. If unit suction pressure is

higher than chart pressure, remove refrigerant

until chart pressure is reached.

Unit Single-Phase Compressors

COMPRESSORS OF THE SPLIT CAPACITOR

(PSC) TYPE require an equalized system pressure

to start. When supply voltage is within 10% limit and

compressor does not start, give compressor a tem

porary capacitance boost. See Carrier Standard

Service Techniques Manual, Chapter 2, for details.

STRAINER VAPOR REVERSING "

e

" COIL

ACCUMULATOR

mm.

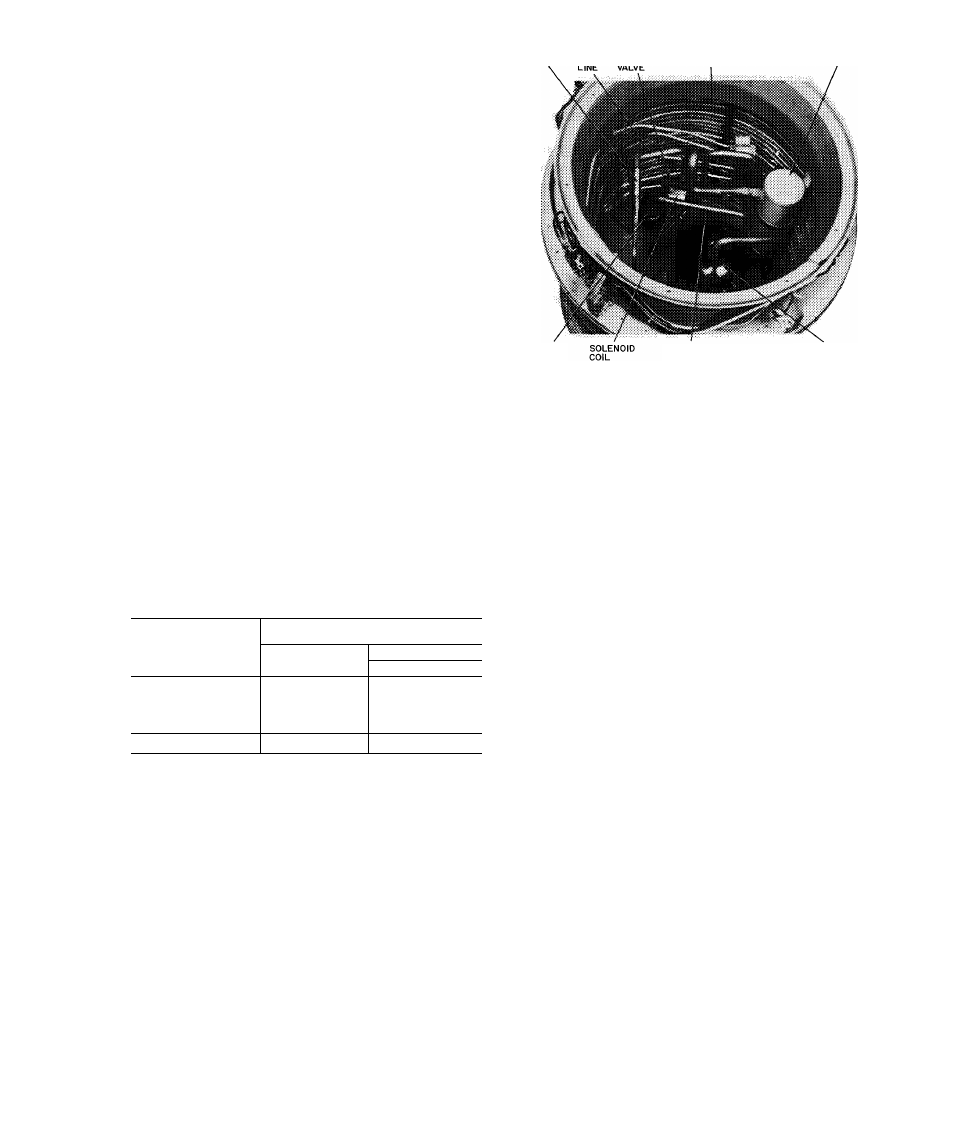

Compressor Removal

— See Table 7 for com

pressor information and Fig. 7 for component

location. Shut off power to unit. Remove refrigerant

from unit using refrigerant removal methods de

scribed in Carrier Standard Service Techniques

Manual, Chapter 1, Refrigerants.

Be sure system pressure is 0 psig before proceeding.

Table 7 — Compressor Data (60 Hz)

UNIT

i

38QB

i

PRODUCTION COMPRESSOR

V/PH

Model*

Oil Recharge

Ounces

i

018

CRA1-0150-PFV

51

1 ""TM""

024

I

208-230/1

MD2314GE

44

1,3

030 I

MD3214GE

44

1,3

036,1

MD3514GE

44

042

1

230/1

PC4616BD

64

‘Refer to Service Parts catalog for replacement compressor model

numbers

Follow safety codes. Wear safety glasses and

work gloves. Have quenching cloth available.

CAUTION: Aíuíiwíusííj ititsing

h m&á

ir? uiüí

^

m 'phm

Oil líífesííg Of damage may result.

1. Remove top cover as described in Installation,

Step 1.

2. Disconnect high- and low-voltage field wiring

and fan motor leads from capacitor and

contactor.

3. Remove screws holding discharge grille in place.

Lift grille from unit.

4. Disconnect compressor leads (crankcase heater,

low-pressure switch, defrost thermostat and

solenoid coil) from electrical components and

pull them thru the wire access opening into the

MUFFLER

HOT GAS

DISCHARGE LINE

COMPRESSOR

Fig. 7 — Component Location

coil section. Lift fan orifice/control ring after

pinching and pressing down on 3 plastic pins

of tube supports.

5. Remove louvered casing by taking out 16 screws

securing it to the cabinet and sliding it away

from the coil.

6. Using a midget tubing cutter, cut liquid and

discharge lines on the coil and suction and

discharge lines at a convenient place near the

compressor for easy reassembly with copper

slip couplings.

CAliXiOK: Excmive

cmpp&t

7. After plugging connections, remove condenser

coil by pinching plastic pins of tube supports

that extend into basepan and lift vertically.

Set coil on a clean, flat surface.

8. Remove compressor holddown bolts and slide

out compressor. Remove crankcase heater.

have ftm extiugaisfeef âïtdior qtjieucbifig

cîoîît

m oil vapor igastes,

9. Carefully unbraze suction and discharge line

piping stubs from compressor after noting posi

tion of stubs to assist when reinstalling.

10. Install new compressor, placing crankcase

heater around compressor. Be sure compressor

holddown bolts are in place.

11. Replace coil; braze suction and discharge lines

to compressor piping stubs (at points where cut.

Step 6); rewire compressor and leak test.

12. Replace fan orifice/control ring; connect com

pressor wires after feeding them thru control

ring; replace fan/grille assembly and rewire;