Carrier 380B User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

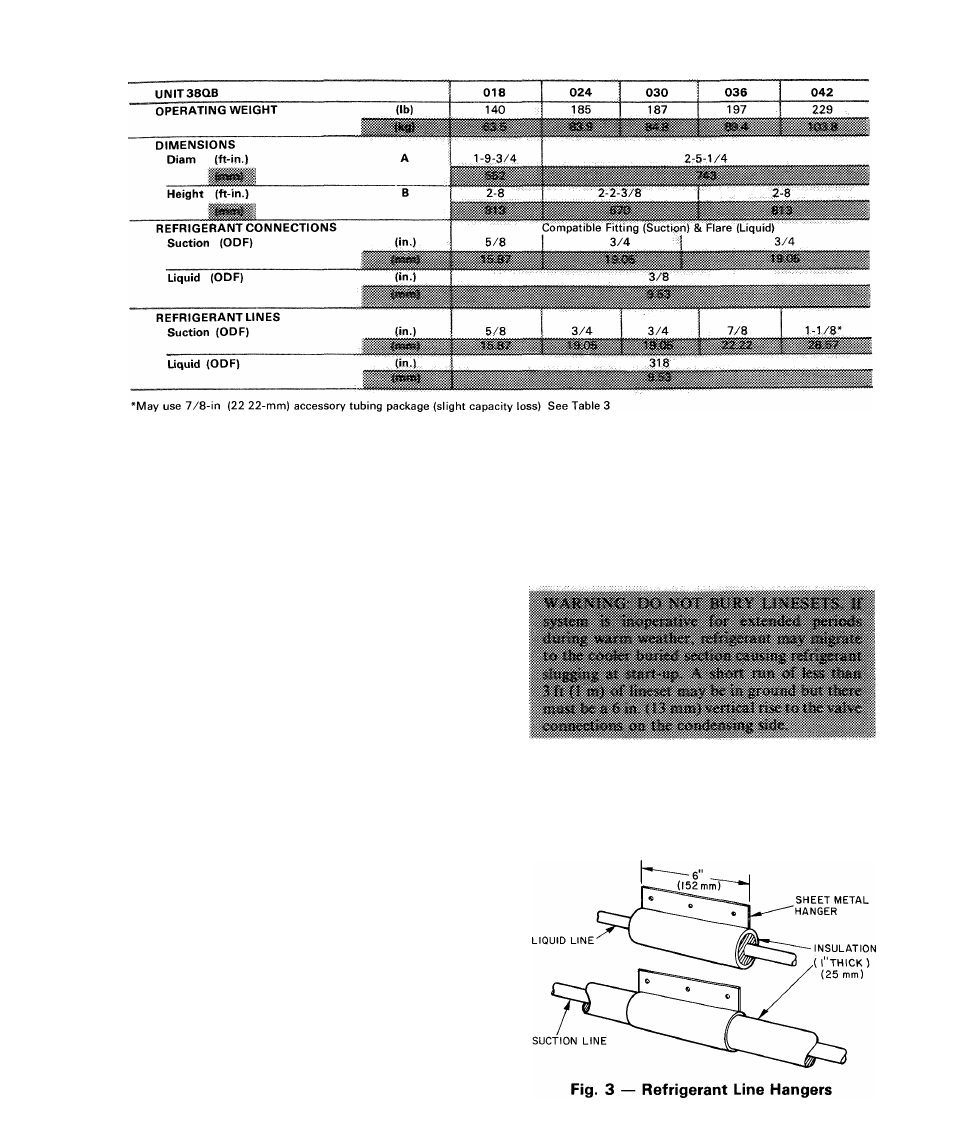

Table 2 — Installation Data (Fig. 1)

required replacement piston is factory supplied with

specified 38QB outdoor unit. Replace piston as

described under AccuRater™ Servicing on page 13.

Top Cover Removal — Top cover can be removed

for wiring or servicing heat pump. Loosen decora

tive strip and slide down off screw heads. Remove

3 screws in connector plate and 2 screws on front of

unit. Loosen remaining 4 screws. Lift top from unit

(See Fig. 1).

Step 2 — Mount Outdoor Heat Pump

ON THE GROUND: MOUNT ON A SOLID,

LEVEL CONCRETE PAD (See Fig. 1). Swing 3

legs down and lock in position, except when using

accessory rack. Use accessory heat pump rack

(Fig. 2) in areas where prolonged subfreezing tem

peratures or heavy snow occur. (Refer to installation

instructions included with rack.) Drainage holes in

unit base must not be obstructed.

ON THE ROOF: MOUNT UNIT ON A LEVEL

PLATFORM OR FRAME. Proper precaution

must be taken for support of unit in roof design.

Elevate unit for proper clearance as described under

ground installation above. Plan roof design and

water drainage to prevent unit from setting in water.

Flash all roof openings to prevent leaks.

Roof mounted units exposed to winds above

5 mph (8 km/ h) may require protective wind baffles

(field fabricated) to achieve adequate defrost.

Step 3 — Make Piping Connections

— The

38QB can be connected to indoor units using

Carrier accessory tubing package or field-supplied

tubing of refrigerant grade. See Table 2 for unit

piping connection type and size. See Table 3 for

accessory tubing sizes. For requirements beyond

50 ft (15.2 m), obtain information from local Carrier

distributor. Isolate interconnecting tubing from

framing and ductwork or where tubing runs thru

stud spaces, enclosed ceilings or pipe chases. Use

isolation type hangers. Fig. 3, since rigid fastening

transmits pulsations to structure creating objec

tionable sound.

A capacity reduction will result if accessory tub

ing is used in 38QB042 systems. For example, when

a 25-ft (7.6 m) 7/8-in. (22 mm) accessory package is

used, there is a capacity reduction of 1-1/2 percent.