Carrier 380B User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

With a low-side leak there is always some pressure

in the liquid line. However, compressor motor tem

perature increases because of insufficient suction

gas cooling. This causes internal thermostat to

actuate and stop compressor. When compressor

stops, system pressure equalizes and contacts on

pressure control open. The compressor cannot re

start until leak is repaired and system recharged.

CRANKCASE HEATER is connected across line

side of contactor and operates continuously.

The purpose of the heater is to keep the crankcase

warm during the off cycle and thus prevent dilution

of the oil with refrigerant. This assures good lubri

cation and prevents loss of oil from crankcase

during start-up.

To energize crankcase heater, turn thermostat to

OFF position and close electrical disconnect to heat

pump.

If the electrical disconnect switch to the outside

unit has been off for an extended period of time, the

crankcase heater should be energized for 24 hours

before starting the compressor.

DEFROST CONTROL, consisting of defrost

control board and defrost thermostat, interrupts

normal system heating operation every 90 minutes

to defrost outdoor coil, if the coil saturated suc

tion temperature indicates freezing temperatures.

Defrost control simultaneously stops outdoor fan,

energizes reversing valve solenoid to return system

to cooling cycle (outdoor unit as condenser, indoor

unit as evaporator), and activates accessory electric

heater.

For the heat pump to defrost, 2 conditions are

necessary:

1. Defrost timer contacts must be closed.

2. Refrigerant temperature from outdoor unit must

be cold enough to cause defrost thermostat con

tacts to close. Contacts close at 31 (± 4) F

(-.5 ± 2.2 C).

Every 90 minutes of elapsed running time, the de

frost timer contacts close for 10 seconds. If the

defrost thermostat contacts are closed, the unit

defrosts. The defrost timer limits defrosting period

to 10 minutes. Normally, the frost is removed and

the defrost thermostat contacts open to terminate

defrosting before 10 minutes have elapsed. Defrost

thermostat contacts open at 80 (± 6)F(26.7± 3.3 C)

liquid refrigerant temperature. When defrosting is

terminated, the outdoor fan motor is energized and

reversing valve solenoid is de-energized, returning

unit to heating cycle.

HEAT PUMP CIRCUITS shown in Fig. 6 are re

frigerant flow diagrams for heating and cooling

cycles.

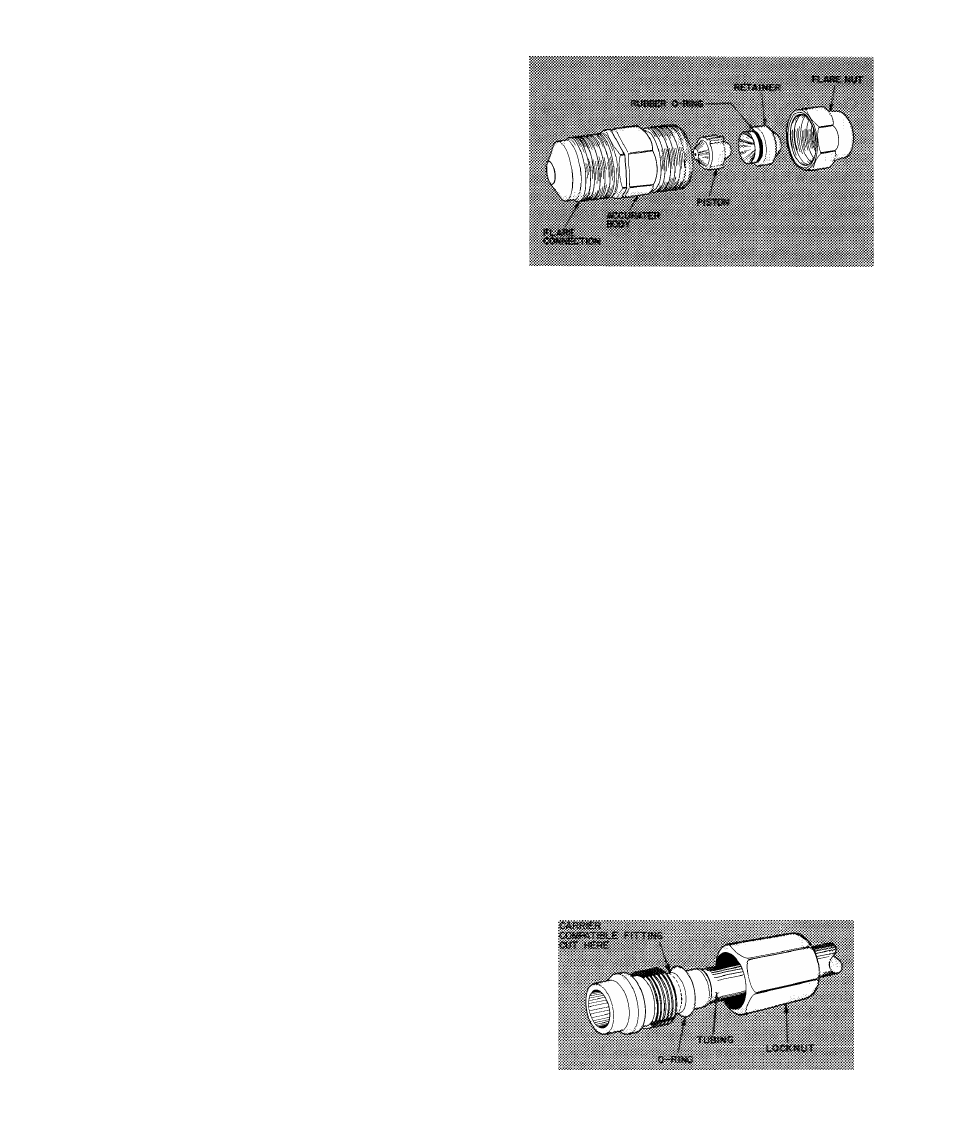

AccuRater™ (Bypass Type) Servicing

— See

Fig. 18 for bypass type AccuRater components. The

piston has a refrigerant metering hole thru it. The

retainer forms a stop for the piston in the refrigerant

Fig. 18 — AccuRater™ (Bypass Type)

Components

bypass mode, and a sealing surface for liquid line

flare connection. To check, clean or replace piston:

1. Shut off power to unit.

2. Pump unit down using Pumpdown Procedure

described previously.

3. Remove liquid line flare connection from

AccuRater.

4. Pull retainer out of body, being careful not to

scratch flare sealing surface. If retainer does not

pull out easily, carefully use Vise Grip pliers to

remove retainer.

5. Slide piston out by inserting a small soft wire,

with small kinks, thru metering hole. Ensure

metering hole, sealing surface around piston

cones and fluted portion of piston are not

damaged.

6. Clean piston refrigerant metering hole.

7. Replace retainer O-ring before reassembling

bypass type AccuRater. Carrier O-ring part no.

is 99CC501052.

LIQUID LINE STRAINER (protects AccuRater)

made of wire mesh is located in the liquid line inside

38QB unit behind liquid line service valve. Liquid line

is belled and sweat connected where strainer is lo

cated . If strainer is plugged, unsweat belled liquid line

connection and replace strainer. See Fig. 7.

Compatible Fitting Repair

LEAKING MECHANICAL CONNECTION —

Frontseat outdoor section service valves after reliev

ing refrigerant pressure in system. Back locknut off

Carrier Compatible Fitting onto tube. Cut fitting

between threads and O-ring shown in Fig. 19.

Fig. 19 — Carrier Compatible Fitting

13