Fig. 5 — control circuit connections, Start-up, Refrigerant charging – Carrier 38EB User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

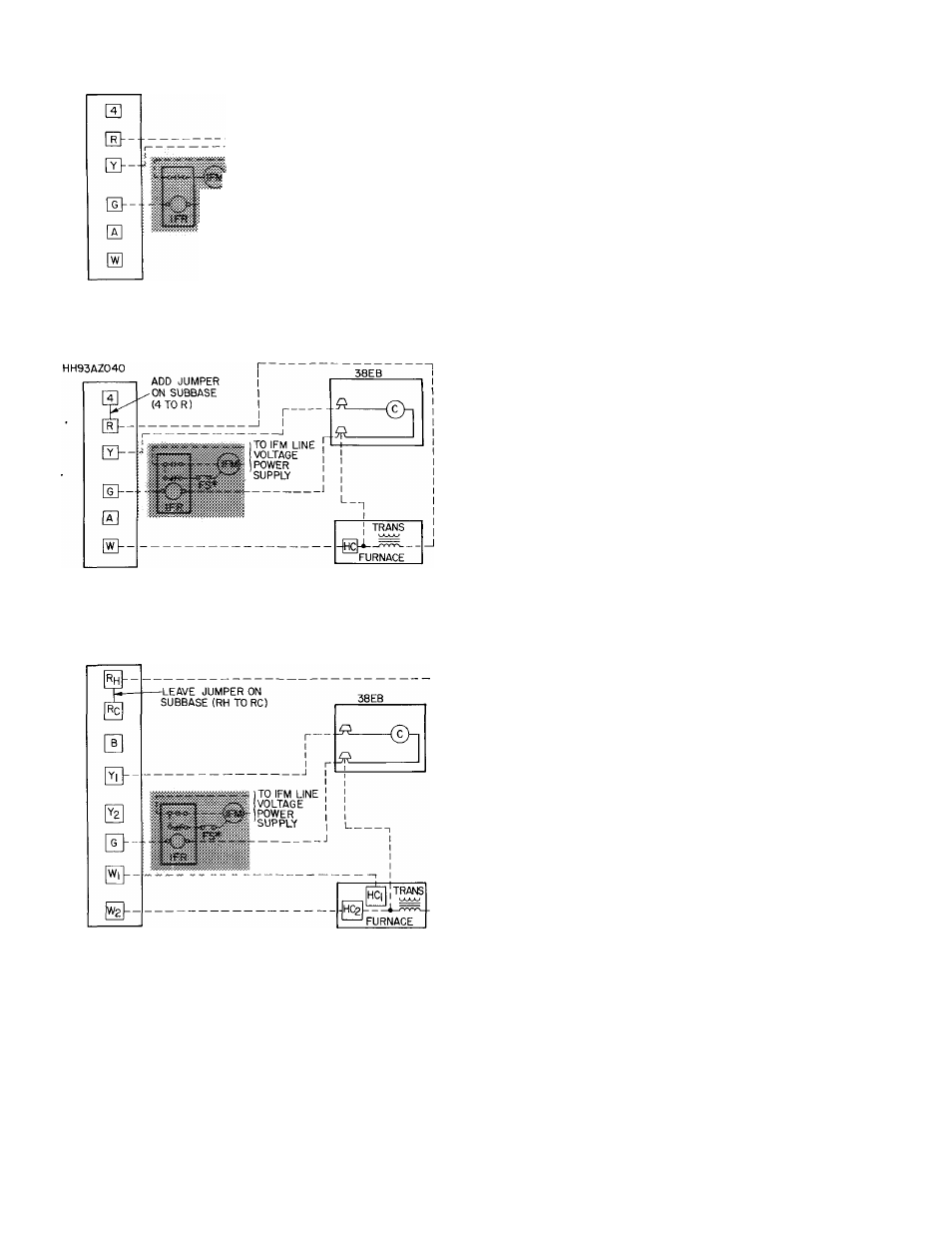

THERMOSTAT SUBBASE

HH93AZ042 OR

HH93AZ040

38EB

I

- j

TO IFM LINE

VOLTAGE

:}“\POWER

SUPPLY

“©n

TRANS

ARRANGEMENT A-(COOLING ONLY)

THERMOSTAT SUBBASE

ARRANGEMENT B-ONE TRANSFORMER

(COOLING AND ONE-STAGE HEATING)

THERMOSTAT

SUBBASE

HH93AZI76

ARRANGEMENT C-ONE TRANSFORMER

(COOLING AND TWO-STAGE HEATING)

IFR, FS and IFM are located in furnace on heating-cooling

applications If accessory IFR is required for cooling-only

applications, locate (IFR) in fan coil

‘Connect FS to low-speed indoor fan terminal when 2-speed fan

is used

C — Contactor (12-va)

Trans — Transformer

FS — Fan Switch

HC — Heating Control

Field Splice

IFM — Indoor Fan Motor

________ Field Wiring

IFR — Indoor Fan Relay

________ Factory Wiring

NOTE Refer to unit wiring label for wire colors: C to G and C to Y

connections

>• Fig. 5 — Control Circuit Connections

START-UP

1. Backseat (open) liquid and suction line service

valves.

2. Set thermostat selector switch at OFF.

3. Set room thermostat at desired temperature.

Be sure this temperature is below indoor ambient.

4. Close electrical disconnects energizing entire

system.

5. Set room thermostat at COOL and fan switch at

FAN or AUTO, as desired. Operate unit for 15

minutes; then check system refrigerant charge.

See Refrigerant Charging, below.

Motors and controls are designed to operate satis

factorily in the voltage range shown in Table 4. If

necessary to use manifold gages for servicing, refer

to Carrier Standard Service Techniques Manual,

Chapter 1, Refrigerants, page 1-5, Fig. 8 for bypass

method of returning charge to system. Removal of

liquid line charging hose without following these

precautions could result in some loss of charge.

Refrigerant Charging

CAUTION: To

Do sot morchsrge sysiiem. As ovorcbsf®e

cas

Condensing units contain correct operating

charge for complete system when connected to

Carrier-approved evaporators of same capacity as

condensing unit with 25 ft or less of Carrier accessory

tubing or field-supplied tubing of recommended

size. For every 10 ft of liquid line of recommended

size over 25 ft, add refrigerant charge as follows: .41b

for 3/8-in. line; .28 lb for 5/ 16-in. line. On all other

systems, adjust charge for correct operation as

applicable.

Service port connections are provided on liquid

and suction line service valves for evacuation and

charging. See Fig. 1.

TO CHECK, ADJUST OR REPLACE REFRIG

ERANT CHARGE use method recommended in

Table 6. Details of charging methods are listed

below.

Before recharging system, thoroughly evacuate

system and then weigh in refrigerant charge speci

fied in Table 5. Check or adjust charge as required.

Refer to Carrier Standard Service Techniques

Manual, Chapter 1, Refrigerants, for additional sys

tem evacuation and dehydration instructions.

WEIGHT METHOD — Refer to Table 5 or unit

nameplate for correct system refrigerant charge.

Remove any refrigerant remaining in system before

recharging.