Carrier 38EB User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

adapter (Carrier Part No. 28VQ900011) or to cor

rectly sized field-supplied adapter, then make Com

patible Fitting connections.

WARNING: iX> NOT BURY UNESETS- If

fdfigerans

E b. veitkaS Ui« to the vah;« irastxsciioiis

m

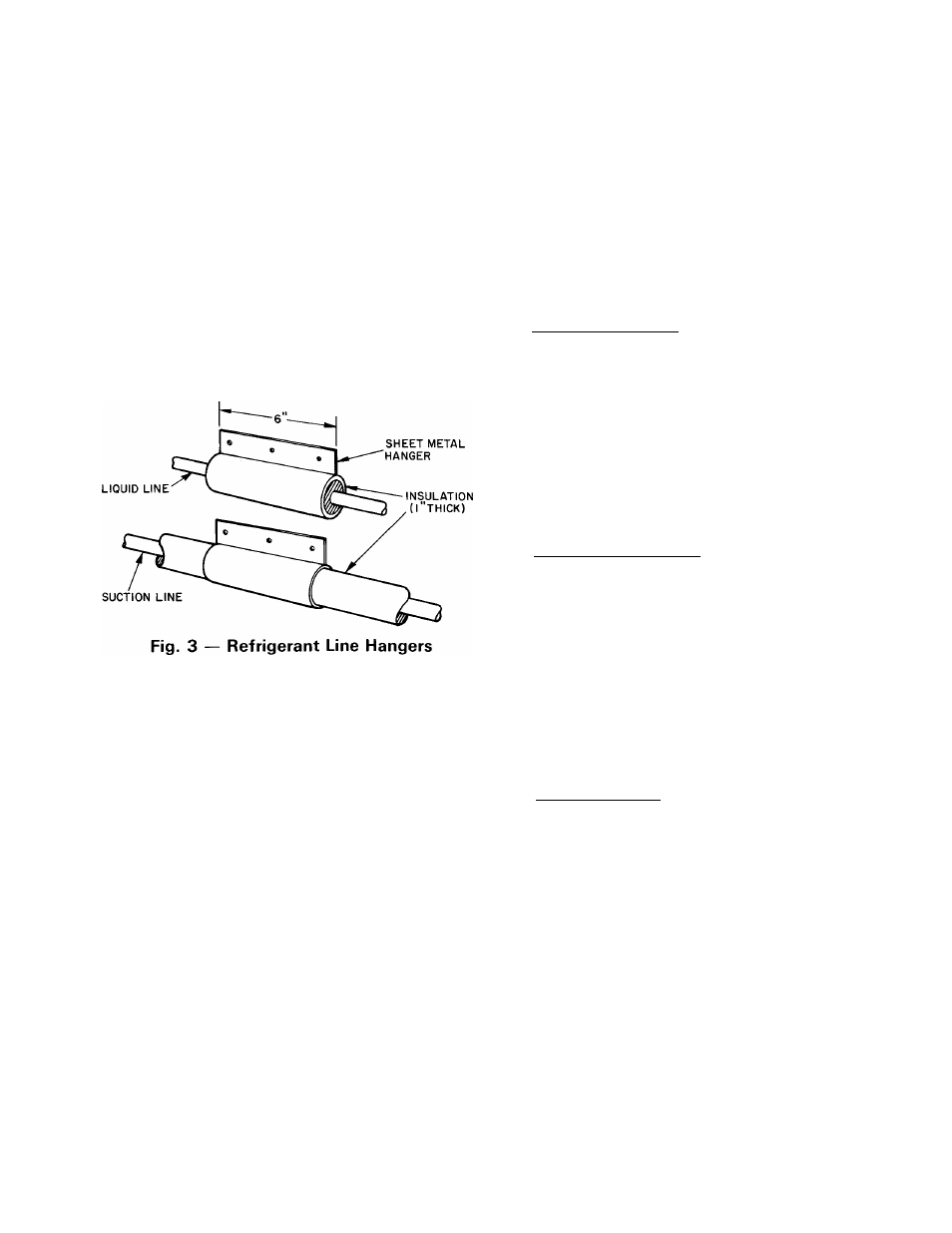

Isolate interconnecting tubing from framing and

ductwork or where tubing runs thru stud spaces, en

closed ceilings or pipe chases. Use isolation type

hanger (Fig. 3) since rigid fastening transmits pulsa

tions to structure creating objectionable sound.

For maximum capacity on 38EB048 and 060 sys^

terns use 1 -1 / 8 in. suction line. A capacity reduction

results if Carrier accessory tubing is used on these

systems. (Example; When a 25-ft accessory tubing

package is used on a 38EB048 system, the smaller

suction line results in a 3% capacity reduction.)

Length of interconnecting tubing may necessitate

refrigerant charge adjustment. Follow special re

quirements described in Start-Up, Refrigerant

Charging, page 6. Do not use less than 10 ft of inter

connecting tubing. On Carrier accessory tubing

packages, do not cut 5/ 16-in. or 1/4-in. liquid line or

7/8-in. suction line. These tubing packages have

swaged ends that, if cut, will not fit into refrigerant

line fittings. Bend or coil excess tubing to fit.

Do not use damaged, undersized or contaminated

tubing. Always evacuate or purge evaporator coil

and tubing system. When purging, use field-supplied

refrigerant, not unit holding charge refrigerant.

When making tubing connections, be sure to pro

vide clearance at unit for electrical connections.

REPLACE

THE

ACCURATER™

REFRIG

ERANT CONTROL PISTON IN THE INDOOR

COIL, if required, before connecting refrigerant

lines. See Carrier Cooling System Capacity Optimi

zation, page 2.

CONNECT REFRIGERANT LINES to fittings on

condensing unit suction and liquid service valves

(Fig. 1). Unit Compatible Fittings permit mechanical

(quick connect) or sweat connections.

Models 38EB048,060 — When using 1 -1 / 8 in. field-

supplied suction line, use field-supplied 3/4-in. by

1-1/8

in.

suction

valve

connection

adapter

(28VQ900011). Sweat connect refrigerant suction

line to 1-1/8 in. end of adapter. Be sure to provide

a heat sink at the service valve to prevent damage

during sweating operation. Connect 3/4-in. end of

adapter to unit suction line Compatible Fitting.

Connect liquid refrigerant line to unit. When a

7/8-in. field-supplied suction line is used, provide a

field-supplied 3/ 4-in. to 7/ 8-in. suction line adapter.

(Not necessary if 38LS accessory tubing is used.)

Mechanical Connection — (Mate one set of connec

tions at a time.)

1. Loosen nut on Compatible Fitting one turn. Do

not remove.

2. Remove plug and be sure O-ring is in the groove

inside the Compatible Fitting.

3. Cut tubing to correct length, deburr and size as

necessary.

4. Insert tube into Compatible Fitting until it

bottoms. Tighten nut until it bottoms on back

coupling flange. Keep tube bottomed in Compat

ible Fitting while tightening nut.

SweatT/onnection — (Use refrigerant grade tubing.-)

1. Remove locking nut, rubber O-ring and Schrader

core and cap from valve service port.

2. Cut tubing to correct length, deburr and size as

necessary.

3. Insert tube in Compatible Fitting until it bottoms.

Wrap top and bottom of service valves in wet

cloth to prevent damage by heat. Solder with low-

temperature (430 F) silver alloy solder.

4. Replace Schrader core and cap.

5. Evacuate or purge system using field-supplied

refrigerant.