Description of operation – Wilkerson DE5 User Manual

Page 3

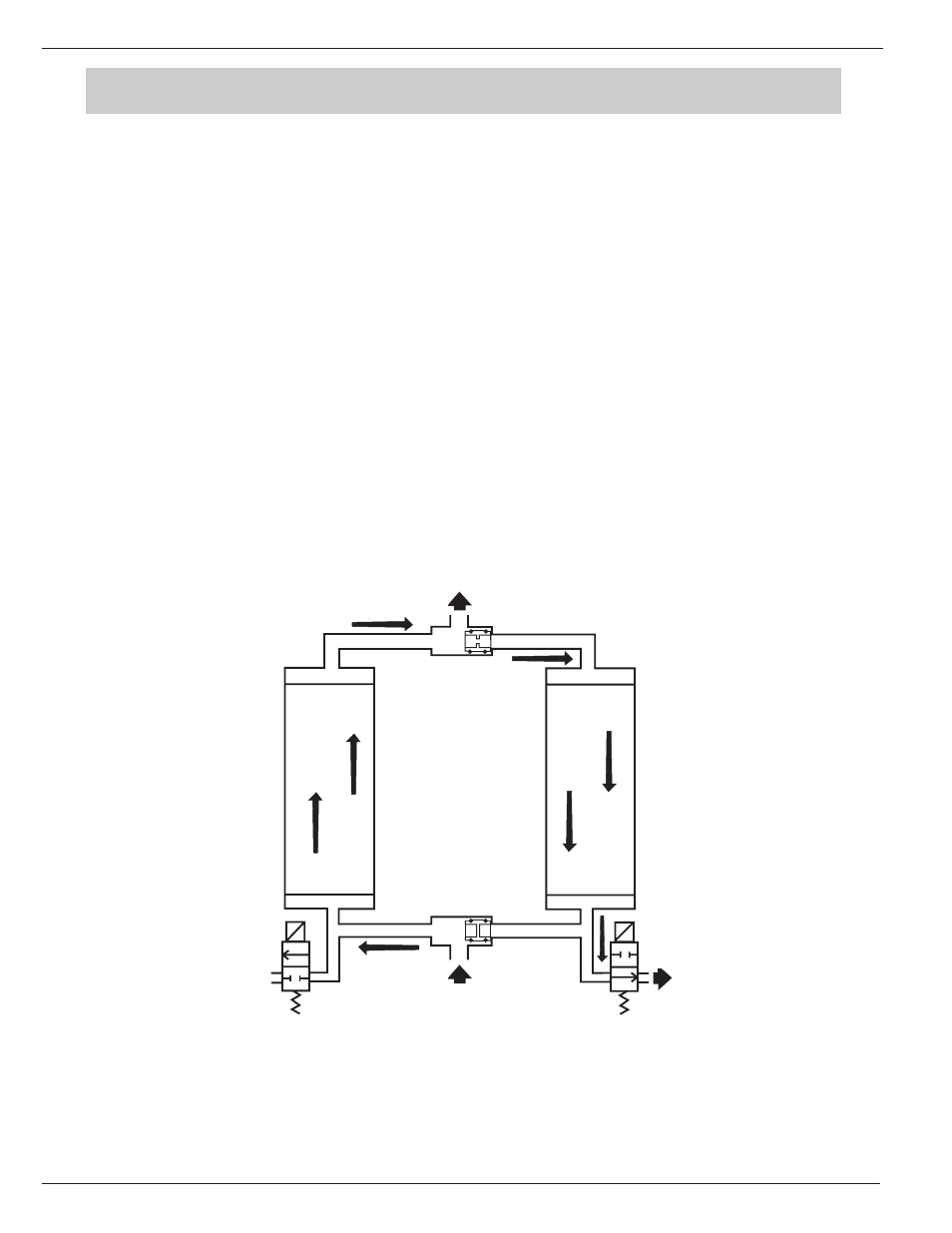

DESCRIPTION OF OPERATION

Wilkerson DE series compact heatless air dryers employ the principles of pressure swing

adsorption (PSA). The operation is fully automatic and relatively little maintenance is required.

The dryers utilize two identical desiccant towers, a metering orifice, two shuttle valves, and two

2-way AC operated solenoid valves controlled by a solid state electronic timer. Wet air at line

pressure enters and flows through one of the towers where nearly all the water vapor is adsorbed

while the other tower is being regenerated. A repressurization period follows the regeneration

period. Every 60 seconds, the process is reversed, providing a continuous flow of dry air.

In the flow schematic shown below, Valve A (closed, de-energized) and Valve B (open, energized)

allow the inlet shuttle valve to direct the inlet air to flow into Tower A (drying). A portion of the dry

outlet air is allowed to flow through the outlet shuttle valve purge orifice into Tower B. This dry

purge air expands to nearly atmospheric pressure, sweeping the water out of the desiccant as it

flows through Tower B (regenerating) and out of the Valve B (energized) exhaust port. The timer

controls the cycling of normally closed solenoid valves.

The orifices are fixed and are sized by the factory based on flow, pressure and dew point required.

Flow Schematic

Figure 2

Instruction Manual / DE3, DE4 and DE5

Wilkerson Compact Heatless Air Dryers

EXHAUST

SOLENOID

VALVE A

INLET

SHUTTLE

VALVE

DESICCANT

TOWER A

OUTLET SHUTTLE

VALVE WITH

PURGE ORIFICE

DESICCANT

TOWER B

DRY AIR

TO APPLICATION

EXHAUST

SOLENOID

VALVE B

PURGE

AIR

EXHAUST

WET AIR IN

DE3, DE4 and DE5

DESICCANT

TOWER A

EXHAUST

SOLENOID

VALVE A

EXHAUST

SOLENOID

VALVE B

PURGE

AIR

EXHAUST

DESICCANT

TOWER B

DRY AIR

TO APPLICATION

OUTLET SHUTTLE

VALVE WITH

PURGE ORIFICE

INLET

SHUTTLE

VALVE

WET AIR IN