Wilkerson PC6 User Manual

Warning

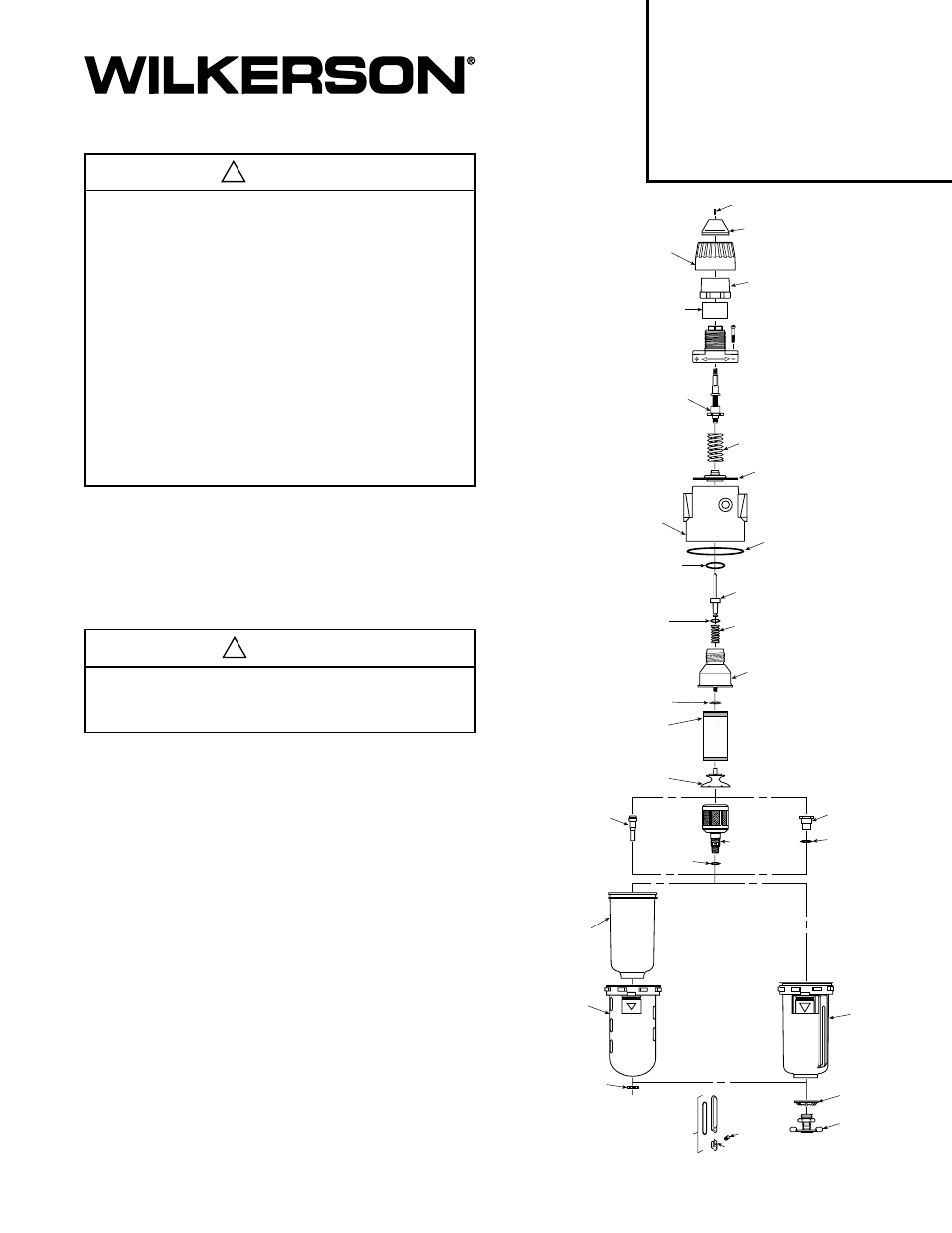

SCREW

ADJUSTING

KNOB

ASSEMBLY

LOCK KNOB

PANEL

MOUNT

NUT

TAMPER

RESISTANT

KIT (optional)

DIAPHRAGM

ASSEMBLY

REGULATING

SPRING

ADJUSTING

STEM

ASSEMBLY

VALVE STEM

O-RING

BODY

NNR

BOWL

O-RING

FILTER

ELEMENT

GASKET

ADAPTER

NNR

VALVE SPRING

O-RING

BAFFLE

NNR

FLEX-DRAIN™

(plastic bowls only)

O-RING

AUTOMATIC

MECHANICAL

DRAIN

O-RING

BOWL

INSERT

TRANSPARENT

BOWL

BOWL

GUARD

SIGHT GAUGE

KIT

NUT

(for use with

Auto. Mechanical

Drain)

SCREW

RETAINER

METAL

BOWL

INSERT

RETAINER

PETCOCK

(for metal

bowls only)

INSTALLATION

Install the Filter/Regulator as close as possible to the application. The

inlet port is marked with an arrow cast into the body to indicate the

direction of flow. Gauge ports (1/4") are provided in either side of the

body for installation of a gauge or use as an additional outlet port.

Plug unused port(s). System piping should be same size as regulator

porting. In systems with a cyclic demand, the regulator should be

located upstream of cycling device.

OPERATION

Maximum pressure rating is 150 psig (10 bar) for transparent

plastic bowls, and 200 psig (14 bar) for metal bowls.

Temperature range is 32°F to 125°F (0°C to 52°C) for transparent

plastic bowls, and 32°F to 150°F (0°C to 65.5°C) for metal bowls.

Before turning on the supply air pressure, turn the adjusting knob

counterclockwise until there is no load on the regulating spring. Turn

on the supply air pressure and then turn the adjusting knob clockwise

until the desired secondary pressure is reached. To avoid minor

readjustment after making a change in pressure setting, always

approach the desired pressure form a lower pressure. When reducing

from a higher to a lower setting, first reduce to some pressure less

than that desired and then increase to the desired pressure.

SEE REVERSE SIDE FOR LIST OF MATERIALS

UNSUITABLE FOR USE WITH POLYCARBONATE BOWLS

MAINTENANCE

1. The regulator can be disassembled for servicing without removal

from line.

2. DEPRESSURIZE UNIT BEFORE REMOVING GUARD AND/OR

BOWL.

3. TO DISASSEMBLE: shut off air to the filter/regulator and vent air

line on both sides of unit. Turn adjusting screw counterclockwise

to relieve spring compression. Remove knob, cover cap, screw

cover, and spring. Diaphragm assembly can now be removed.

4. To remove valve from bottom of unit, remove bowl. Remove baffle

and filter element exposing hex nut on adapter assembly.

Remove adapter assembly, valve and spring.

(continued on reverse side)

NNR = NOT NORMALLY REPLACED

WARNING

To avoid unpredictable system behavior that can cause personal injury

and property damage:

•

Disconnect electrical supply (when necessary) before installation,

servicing, or conversion.

•

Disconnect air supply and depressurize all air lines connected to

this product before installation, servicing, or conversion.

•

Operate within the manufacturer’s specified pressure, temperature,

and other conditions listed in these instructions.

•

Medium must be moisture-free if ambient temperature is below

freezing.

•

Service according to procedures listed in these instructions.

•

Installation, service, and conversion of these products must be

performed by knowledgeable personnel who understand how

pneumatic products are to be applied.

•

After installation, servicing, or conversion, air and electrical supplies

(when necessary) should be connected and the product tested for

proper function and leakage. If audible leakage is present, or the

product does not operate properly, do not put into use.

•

Warnings and specifications on the product should not be covered

by paint, etc. If masking is not possible, contact your local

representative for replacement labels.

!

!

WARNING

Product rupture can cause serious injury.

Do not connect regulator to bottled gas.

Do not exceed maximum primary pressure rating.

Installation & Service Instructions

83-861-000

Precision Air Pressure Regulator

Type PC6B Filter / Regulator

ISSUED: April, 2006

Supersedes: July, 2004

Doc.# 83861000, ECN# 060299, Rev.

4

Richland, MI 49083

Tel: (269) 629-5000