Installation, Operation and service, Service kits available – Wilkerson M12 User Manual

Page 2

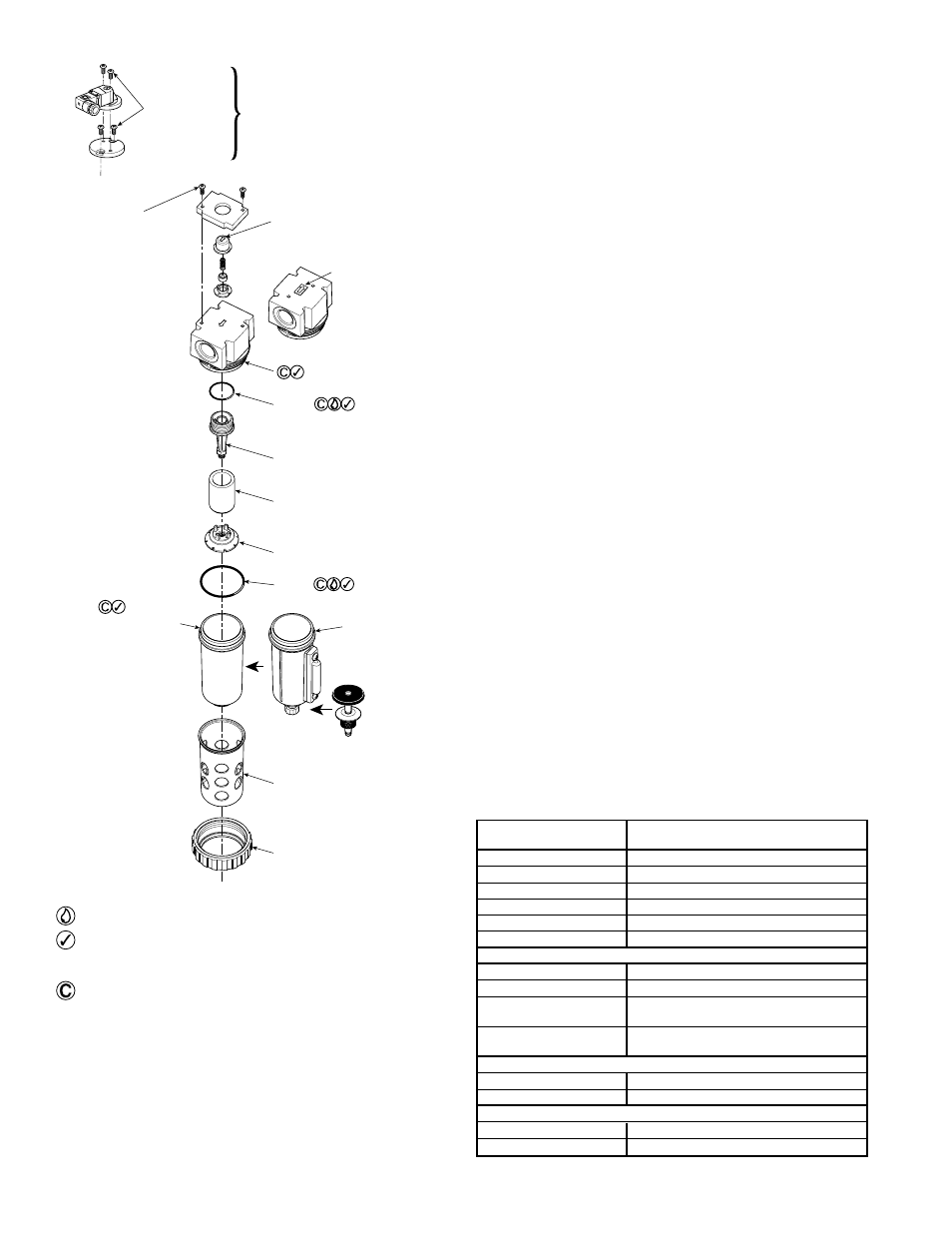

1/4" and 3/8" M12 Coalescing Filter

83-952-000

Installation

1. The filter should be installed with reasonable accessibility

for service whenever possible – repair service kits are

available. Keep pipe or tubing lengths to a minimum with

inside clean and free of dirt and chips. Pipe joint compound

should be used sparingly and applied only to the male pipe

– never into the female port. Do not use PTFE tape to seal

Filter Body

Note Orientation Of All

DPI Parts When

Disassembling & Assembling

(DPI Arrow Opposite

Body Arrow)

Coalescing Filters

Without DPI Only

O-ring

(Locate At

Bottom Of

Threads)

Filter Holder

(Hand Tighten)

Element

Baffle

(Hand Tighten)

O-ring

Bowl Guard

Retaining Collar

(Hand Tighten

Plus 1/4 Turn)

Metal Bowl

(Sight Glass

Shown)

Polycarbonate

Bowl

(See Warning)

(Do Not Scratch

Internal Surfaces)

Manual

Drain

Torque:

0.5 - 0.6 Nm

(4.7 - 5.3 in-lbs)

Torque:

0.5 - 0.6 Nm

(4.7 - 5.3 in-lbs)

Piston

Drain

Optional Electronic

Differential Pressure

Indicator

Using a straight blade

screwdriver, adjust clockwise

to increase differential /

counter-clockwise to

decrease differential.

pipe joints – pieces have a tendency to break off and lodge

inside the unit, possibly causing malfunction. Also, new pipe

or hose should be installed between the filter and equipment

being protected.

2. The upstream pipe work must be clear of accumulated dirt

and liquids.

3. Select a filter location as close as possible to the equipment

being protected and upstream of any pressure regulator.

4. Install filter so that air flows in the direction of arrow on body.

5. Install filter vertically with bowl drain mechanism at the bottom.

Free moisture will thus drain into the sump “quiet zone” at

the bottom of the bowl.

Operation and Service

1. Both free moisture and solids are removed automatically by

the filter. There are no moving parts.

2. Manual drain filters must be drained regularly before the

separated moisture and oil reaches the bottom of the lower

baffle.

3. The coalescing filter element should be removed and replaced

when pressure differential across the filter is 10 psid. The

differential pressure indicator, located on top of the filter

body, gives a visual indication of the pressure differential

across the filter element. Change the filter element when

half or more of the orange piston is above the retaining ring

when air is flowing. For units without a differential pressure

indicator, pressure differential gauges should be used to

determine when the maximum recommended pressure

differential has been reached.

4. Shut off air supply and depressurize the unit before servicing.

5. After servicing, apply system pressure and check for air leaks.

If leakage occurs, Do Not Operate — conduct servicing again.

Service Kits Available

M12

Description

1/4" & 3/8"

Type “B” Element*

MRP-96-301

Type “C” Element*

MRP-96-300

Bowl Guard Kit

GRP-96-345

DPI Repair Kit

FRP-96-300

Electronic DPI Kit

FRP-96-302

Sight Gauge Kit

GRP-96-346

Metal Bowl Kits

Manual Drain

GRP-96-348

Piston Drain

GRP-96-353

Sight Gauge &

GRP-96-349

Manual Drain

Sight Gauge &

GRP-96-352

Piston Drain

Polycarbonate Bowl Kits

Manual Drain

GRP-96-347

Piston Drain

GRP-96-351

Drain Kits

Manual Drain

GRP-96-340

Piston Drain

GRP-96-354

*Element kits include body / bowl seal.

Lightly grease with provided lubricant. (Silicone free)

Inspect for nicks, scratches, and surface imperfections.

If present, reduced service life is probable and future

replacement should be planned.

Clean with lint-free cloth.