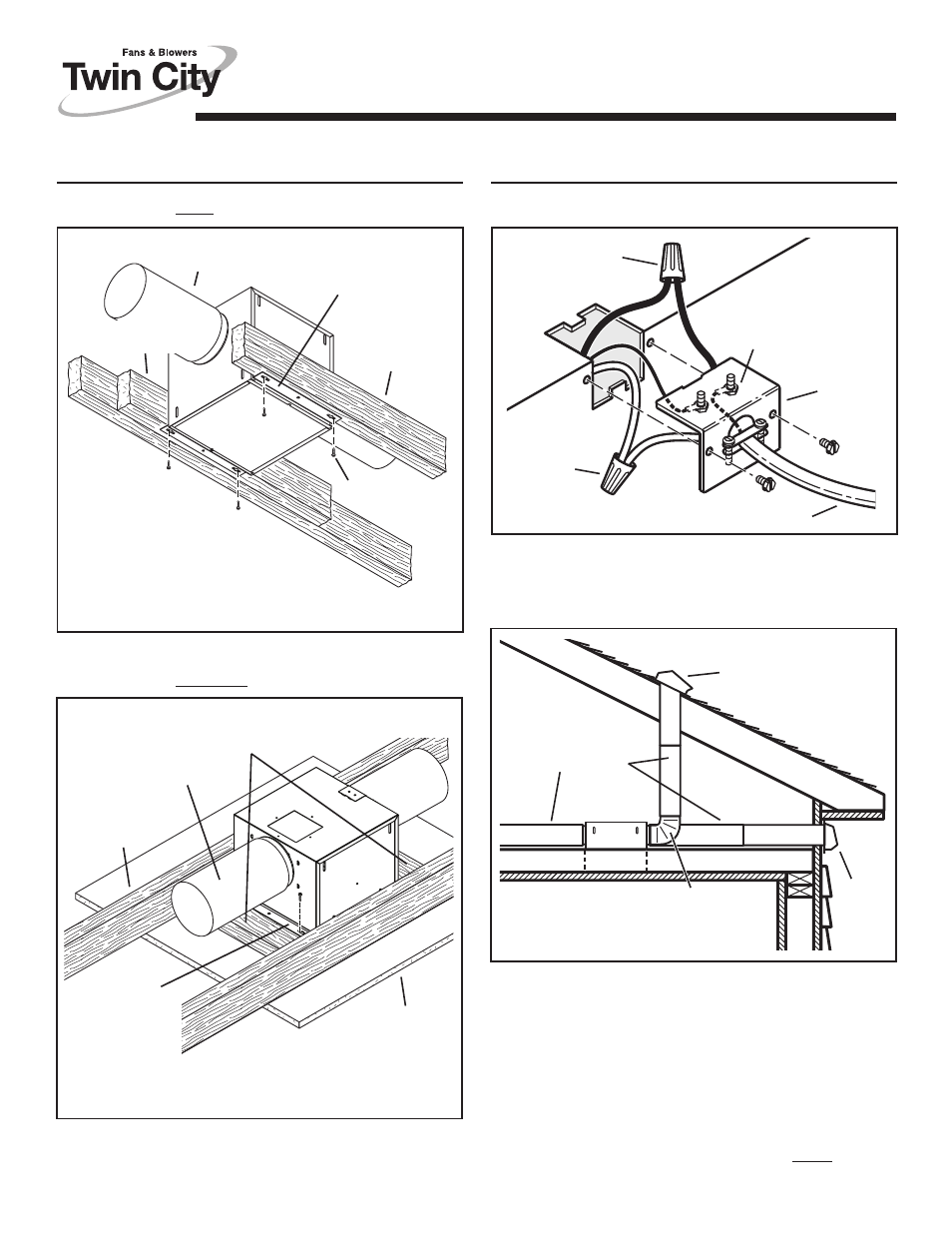

Typical installation, Page 2, New frame construction) – Twin City Inline / Cabinet Ventilators - TL Series User Manual

Page 2: Existing frame construction), Horizontal blower discharge), Remove shipping tape from damper, Remove shipping ring from blower inlet

Page 2

MODELS • T100L • T150L

T200L • T250L • T300L

Page 2

TYPICAL INSTALLATION

MOUNTING

(New Frame Construction)

CEILING JOIST

(16” centers shown)

ROUND DUCT*

MOUNTING

SCREW

Blower factory-shipped

in straight through

discharge position.

Mounting brackets

factory-shipped in

position for ½”

ceiling material.

ADDITIONAL

1½” FRAMING

MOUNTING

(Existing Frame Construction)

TYPICAL INSTALLATION

WIRING

WIRING

PLATE

WHITE

TO

WHITE

BLACK

TO

BLACK

TOP / BACK

OF HOUSING

120 VAC LINE IN

GROUND TO

WIRING PLATE

ROUND DUCT*

FINISHED

CEILING

MATERIAL

CEILING JOIST

(16” centers

shown)

2 X 4 FRAMING

(wide side down)

MOUNTING

BRACKETS

(Attached to

opposite sides

of housing &

upside-down)

DUCTING

(Horizontal blower discharge)

ROOF CAP

ROUND

ELBOW*

ROUND DUCT*

WALL

CAP

IMPORTANT:

Remove shipping tape from damper

Remove the shipping tape from the damper flap and make sure

that damper flap opens and closes freely inside the ductwork. Use

duct tape to make ductwork connections secure and air-tight.

Remove shipping ring from blower inlet

Remove the shipping ring from the blower inlet before operating

the ventilator.

* T100L & T150L use 6” round duct.

T200L, T250L & T300L use 8” round duct.

* T100L & T150L use 6” round duct.

T200L, T250L & T300L use 8” round duct.

Factory-shipped unit installed in new construction.

Factory-shipped unit installed in existing construction.

Two ways to connect ductwork to a factory-shipped unit.

Ventilator can be wired from outside of housing.

Use UL approved connectors to wire per local codes.