Twin City Backward Inclined Hinged Restaurant Exhaust Fan - BHRE - IM-610 User Manual

Page 7

Twin City IM-610

7

Inspection

Inspection of the fan should be completed at the first

30 minutes, 8 hour and 24 hour intervals of satisfac-

tory operation.

30 Minute Interval

Inspect tightness of all hardware, setscrews and motor

mounting bolts. Adjust and tighten as necessary.

8 Hour Interval

Inspect belt alignment and tension. See Belt Adjustment

and tension as necessary

24 Hour Interval

Inspect belt tension, adjust as necessary.

Maintenance

A maintenance program should be established to main-

tain the reliability and performance of the fan. The

frequency of inspection depends on the location and

operating conditions of the fan.

Maintenance is to be performed only by qualified per-

sonnel who are familiar with local codes and regula-

tions and experienced with this type of equipment.

Routine maintenance should cover the following:

a. Tighten all setscrews and hardware.

b. Check belt tension and sheaves for wear.

c. Lubricate fan bearings (see Table 4 for recom-

mended interval and Table 5 for grease types.

d. Cleaning of unit, wheel and grease box.

1. Before performing any maintenance on the fan, be

sure power is turned off and locked in the off

position at the service entrance.

2. Ventilators should be carefully checked at least

once a year. For critical or rugged applications, a

routine check every two or three months is sug-

gested.

3. Always follow the bearing manufacturer's recom-

mended lubrication schedule. If not available, below

is a general guideline:

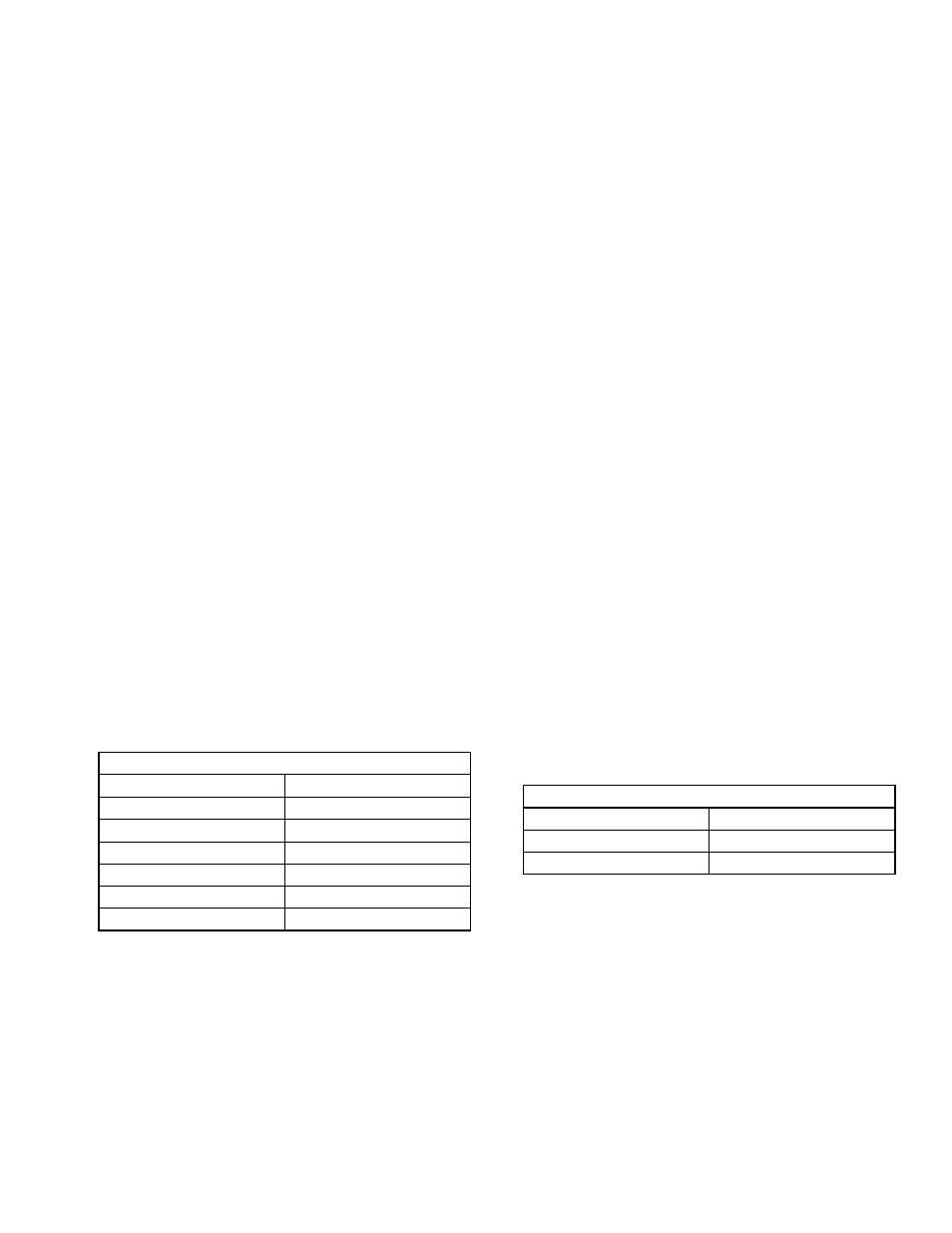

Table 4.

Bearing Greasing Intervals

Fan RPM

Interval (months)

Up to 500

6

500 - 1,000

6

1,000 - 1,500

5

1,500 - 2,000

3

2,000 - 2,500

3

2,500 - 3,000

2

Divide the listed interval by 2 for vertical shaft applica-

tions or for 24 hour operation.

Relubricate while running, if safety permits, until some

purging occurs at seals. Adjust lubrication frequency

depending on condition of purged grease. Hours of

operation, temperature and surrounding conditions will

affect the relubrication frequency required.

4. All motors supplied with Twin City Fan & Blower

ventilators carry a one year limited warranty from

date of shipment. For repairs within the warranty

period, the motor must be taken to the motor man-

ufacturer's authorized service dealer. Contact your

TCF representative for additional warranty details.

5. A periodic motor check should consist of removing

the belt, then spinning the motor shaft with the

power off to be sure the motor turns freely and

the bearings run smoothly.

6. When removing or installing a belt, do not force

the belt over the sheave. Loosen the motor mount

so that the belt can be easily slipped over the

sheave. See Belt Adjustment, on page 8.

7. The belt should be removed and carefully checked

for glazing, cracks, ply separation or irregular wear.

A small irregularity in the contact surface of the

belt will result in noisy operation. If any defects are

apparent, the belt should be replaced.

8. Check sheaves for chipping, dents or rough sur-

faces which could damage the belt. Always replace

sheaves with identical size and type.

9. If the unit is left idle for an extended period, the

belts should be removed and stored in a cool, dry

place to avoid premature belt failure.

10. Check sheave setscrews to ensure tightness.

Proper keys must be in keyways.

11. Check for proper belt alignment. See Figure 10.

Improper alignment leads to excessive belt wear,

vibration, noise and power loss.

12. For two-groove drives, matched belts must be

used.

13. When replacing belts, use the same type & size as

supplied on the unit.

14. The standard pillow block bearings on belt driven

ventilators are factory lubricated and are provided

with external grease fittings. Lubrication bi-annually

is recommended, or more frequently if needed. (see

Table 5). It is recommended to add fresh grease

at start-up, but do not over-grease. Use only 1 or

2 shots of a recommended lubricant with a hand

gun in most cases (see Table 5). Maximum hand

gun rating of 40 psi. Rotate bearings during lubri-

cation where good safety practice permits.

Caution: Greases of different soap bases (lithium,

sodium, etc.) may not be compatible when

mixed. Prevent such intermixing by completely purg-

ing the bearing of old greases.

15. The most frequent causes of bearing failure are not

greasing often enough, using an excessive quantity

of grease or using incompatible greases. Excessive

vibration, especially if the bearing isn't rotating, will

also cause bearings to fail. Bearings must also be

protected from water and moisture to avoid internal

corrosion.

16. During the first few months of operation, it is rec-

ommended to periodically check the bearing set-

screws to ensure tightness.

17. Wheels require attention when moving dirty or

grease laden air. Regular cleaning is required to

avoid imbalance caused by accumulation of grease

or dust.

18. All fasteners should be checked for tightness dur-

ing each maintenance.

Table 5.

Grease Manufacturers

Manufacturer

Grease (NLGI #2)

Shell

Gadus S2 V100 2

Exxon/Mobil

Ronex MP