Twin City Backward Inclined Hinged Restaurant Exhaust Fan - BHRE - IM-610 User Manual

Page 11

Twin City IM-610

11

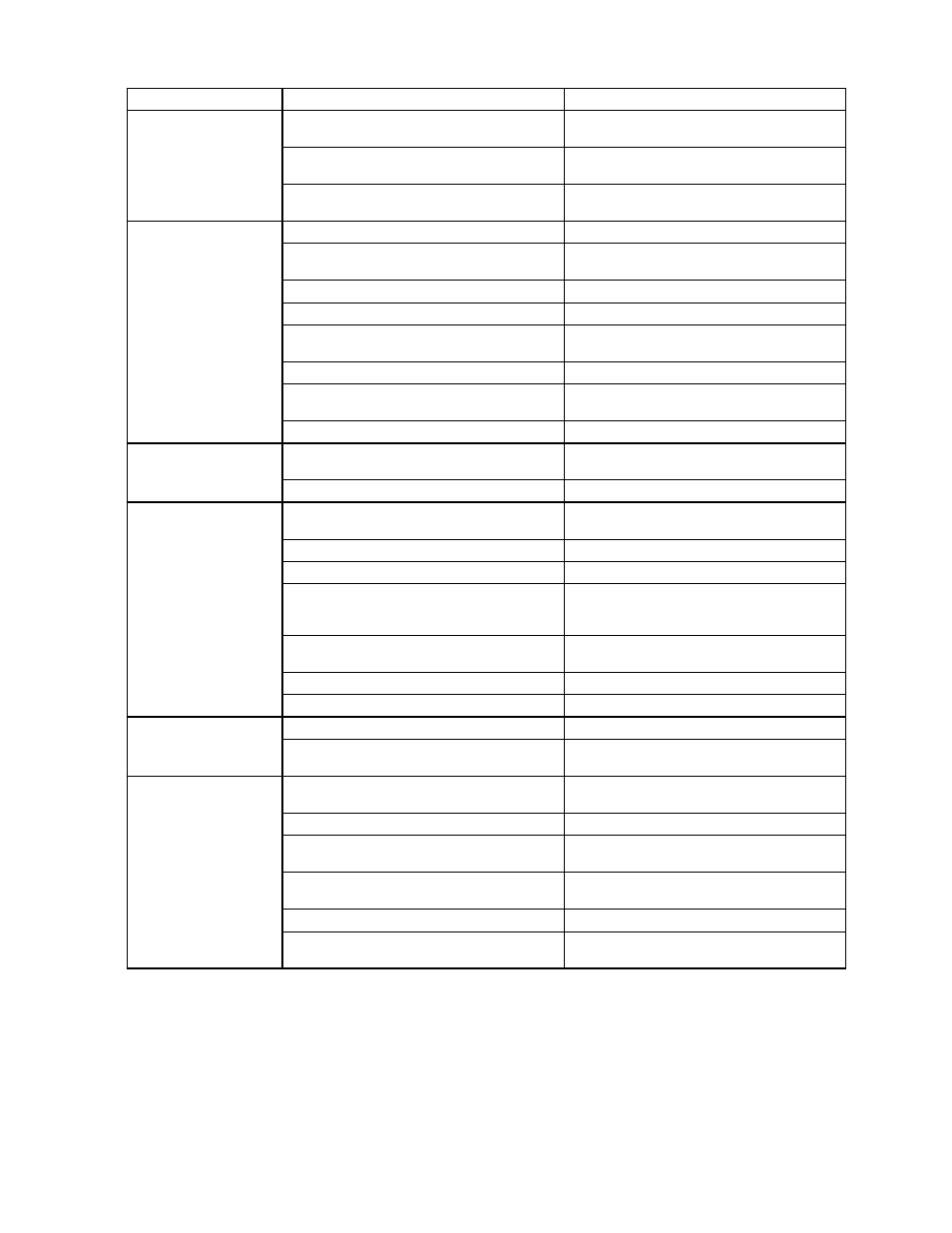

Symptom

Cause

Corrective Action

Fan does not operate

Electrical Supply

Check disconnect switch, fuses/breakers.

Check for correct supply voltage.

Drive

Check for broken belts. Tighten loose belts,

see Belt Adjustment

Motor

Check overload protection on motor. Verify

correct motor horsepower.

Too little air

Wheel rotating in wrong direction

Check wheel rotation, see Fig. 8, P.6

System resistance too high

Check system backdraft dampers, ductwork

and filters.

Fan speed lower than design

Tighten belt; close variable speed sheave.

Dampers closed

Inspect and repair.

Improper wheel alignment

Center wheel on inlet, check wheel gap/over-

lap against Fig. 7, P.6

Excessive dirt/grease on wheel

Clean wheel.

Fan inlet/outlet is restricted

Remove obstruction, check for damage or

unbalance.

Filters (if applicable) are dirty or clogged

Clean or replace filters.

Too much air

System resistance lower than expected

Reduce fan speed to reach required operat-

ing point.

Fan speed higher than design

Adjust fan speed.

Excessive Noise or

Vibration

Wheel hitting inlet

Center wheel on inlet, check wheel gap/over-

lap against Fig. 7, P. 6

Loose sheave or wheel

Align and tighten.

Wheel out of balance

Clean wheel; check wheel balance.

Bearings

Lubricate bearings, replace defective bear-

ings; tighten setscrew or bearing bolt, align

bearings.

V-belts

Mismatched belts, replace with matched

belts; Adjust belt tension, replace worn belt.

Fan not properly anchored

Secure fan base, see Table 2, P. 3

Loose components

Tighten loose hardware.

Excessive Horsepower

Fan

Check wheel rotation; reduce fan speed.

System resistance too high

Check dampers; re-size ductwork; check fan

inlet conditions; check filter.

Motor Overloads/

Overheats

Motor improperly wired

Check motor wiring against wiring diagram

on motor nameplate.

Incorrect wheel rotation

Change wiring leads to correct rotation.

Undersized motor

Check motor ratings against cataloged per-

formance.

Fan rpm too high

Check fan rpm; open variable pitch sheave

on motor.

Over/Under line voltage

Contact power company.

Fan

Check for bent shaft; check for proper belt

tension; check for damaged bearings.

Table 6.

It is recommended that the users and installers of this equipment familiarize themselves with AMCA Publication

#201, "Fans and Systems" and publication # 202 "Troubleshooting" which are published by the Air Movement

and Control Association (AMCA), 30 West University Drive, Arlington Heights, Illinois 60004. www.amca.org