Top Flite Phasoar 035 User Manual

Page 12

the fuselage. Use your sanding block to

now sand the top, rear sheeting and the

forward radio hatch and nose block piece

flush w i t h the fuselage sides. You can

also now sand the top forward hatch and

nose-block contours to shape as shown in

the plans, no need to round corners yet.

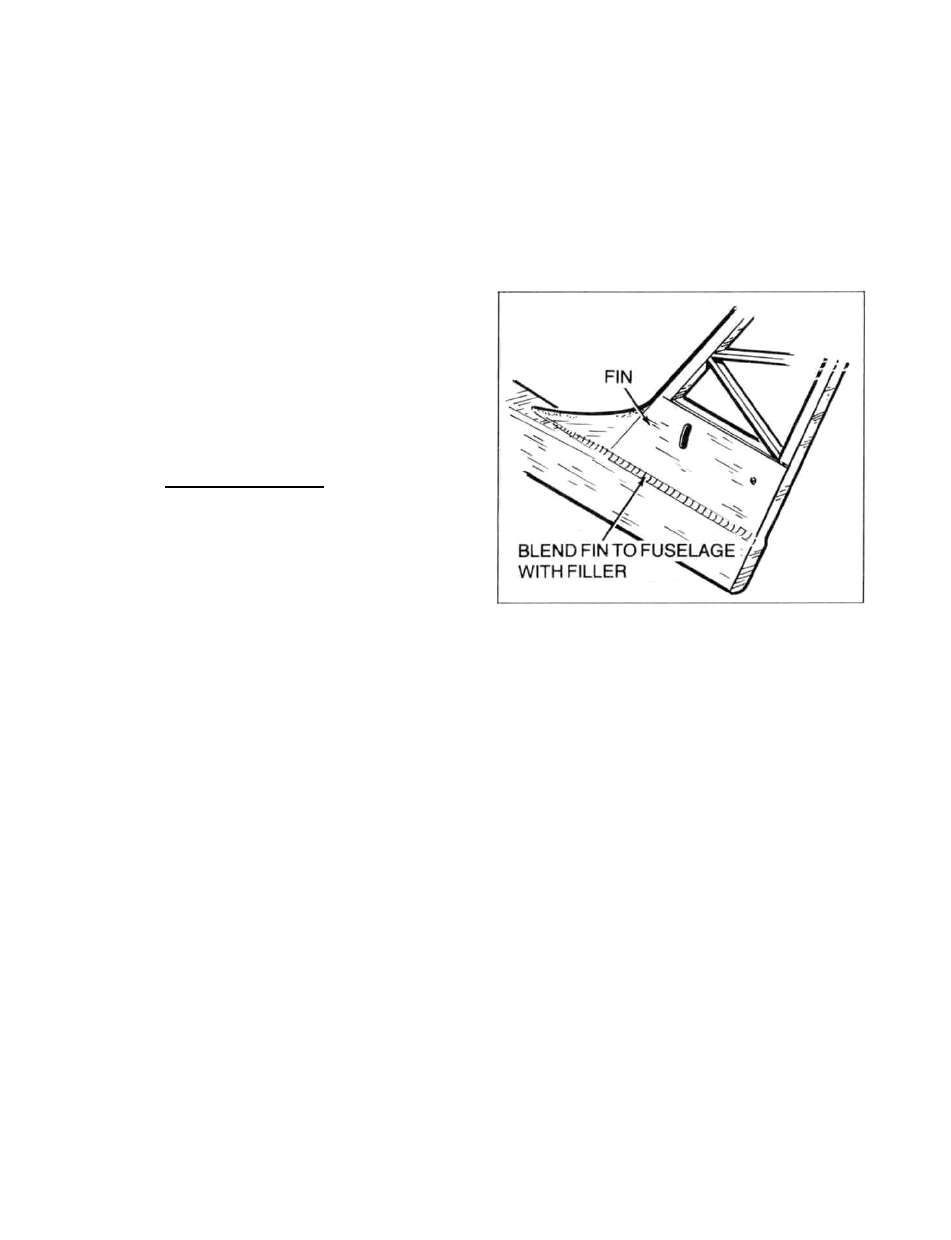

28. From your parts bag, locate the 1/4" shaped

fin/fuselage fairing. Use your sanding

block to adjust the angles if needed and

glue in place. As shown, this is now

trimmed to fair the fin leading edge into

the top, rear of the fuselage.

29. Finally, push the 1/4" length of aluminum

tubing that's in the rear pivot hole about

halfway out, apply just a bit of adhesive

to its outer surface (5-minute epoxy or

slow-cure CA) and push i t back in place in

the fin.

30. with the exception of contouring and final

sanding, your fuselage should be complete.

XI. FINAL ASSEMBLY

It's often been said that the difference between a

good model and a great one is sandpaper and the

willingness and a b i l i t y to use it. This point in

construction can l i t e r a l l y make or break the

performance and the look of your model. Since the

PHASOAR is an obvious candidate for use of

MonoKote, keep in mind that the surface preparation

of the wood w i l l dictate the finished, covered look

of your model. Referenced use of " f i l l e r " in the

following text. refers to products such as

M i c r o F i l l , Model Magic F i l l e r , or something

similar. These products dry quickly, are very

light, and MonoKote goes over them nicely.

Let's start w i t h the fuselage, since the other

components should, by now, be sanded and about

ready to use.

1. Note the lower left corner of Cross Section

F-F on the plans. This demonstrates about

the correct amount of radius that can and

should be sanded into the fuselage bottom.

As this sanding radius moves aft, toward

the fin post, and the fuselage diminishes

in width, the result w i l l be a pleasant

looking oval shape. Next, sand the radio

hatch and nose sections. Use a rougher

grit of paper at first, followed by the

finer #220 to do the job nicely. The last

section to tackle is the top, rear of the

fuselage - back and including the fin

fairing and f i n leading edge. Take every

effort needed to sand this structure to the

point that it looks and feels l i k e one

piece. You w i l l note that where the T-1

fin sides meet the fuselage sides, there is

a disparity in wood thickness resulting in

a kind of "tip." On our prototypes we

handled this by sticking a length of

masking tape lengthwise about 3/16" above

this joint, on T-1. Then we carefully

sanded down the fuselage side(s) to as

close to T-1 as possible (the masking tape

was there to protect T - 1 in case we got too

close). Then with the tape s t i l l in place.

we used f i l l e r to "fair-in" this joint,

feathering the material carefully. When

the f i l l e r was dry, the tape was removed

and we used very light sandpaper to finish

feathering the joint.

2. Use your sanding block to sand the trailing

edge of the f i n f l a t and straight.

3. The last step in preparing the fuselage for

covering is to sand the fin/rudder

combination together, as a single unit.

Start by using masking tape to accurately

position the rudder to the fin. Now use

your sanding block to accurately match the

side view shape of the rudder to the

fin/fuselage. Once that's done, remove one

of the pieces of tape from one side only

and lay the structure down on a flat

surface - taped side down. Use your

sanding block to now sand the rudder's

cross-section shape into the fin/fuselage,

but only about halfway. Add another piece

of tape to the now sanded side, f l i p the

structure over, remove the tape and repeat

the sanding operation. After a couple of

passes on each side, you should be about

where you want to be; a fin w i t h a true

leading edge and a rudder with a true

t r a i l i n g edge and everything in between

accurately matched. The leading edge of

the rudder can now be beveled as shown on

the plans, thus f a c i l i t a t i n g left and right

movement when hinged w i t h MonoKote.

Once this is done, locate and remove the

1/32" ply rudder horn from its die-cut

12