Top Flite Phasoar 035 User Manual

Page 10

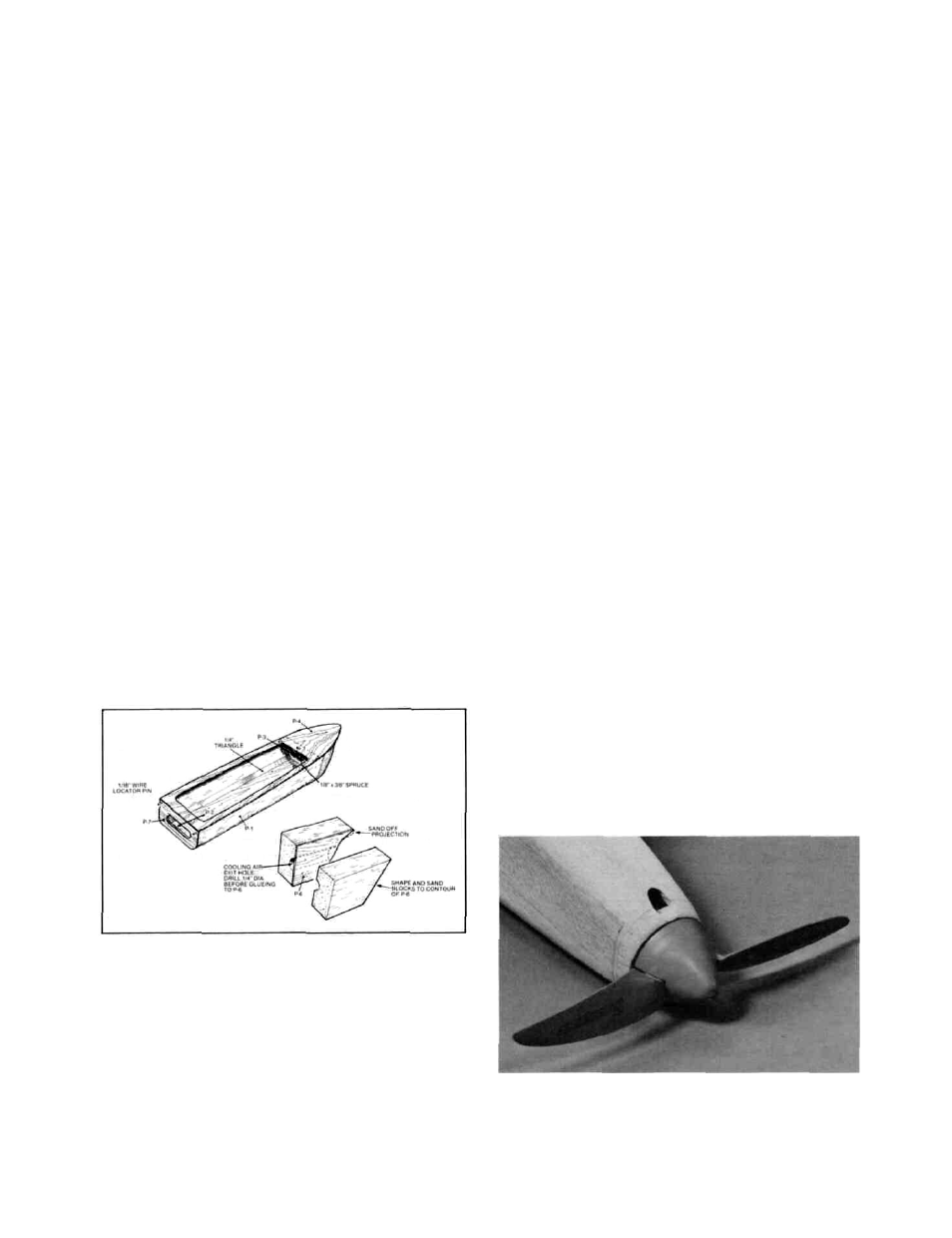

bottom left triangular stock. Mark with a

pencil where this occurs and use a DREMEL

to relieve this area. Once the motor is in

place, d r i l l two 1/8" diameter holes in F-

3 for mounting w i t h two 4-40 x 1/2" screws.

Remove motor and screws - set aside.

Note: For a MABUCHI 380 motor, no

special rotating is required, but metric

mounting screws are needed (not supplied).

15. Using 1/16" balsa sheet stock, glue bottom

sheeting in place (cross-grain) from rear

of F-4 back to end of fuse sides.

16. Glue 1/8" pod screw plate in place between

1/8" fuse longerons and against rear of F-

5.

17. Tack glue die-cut P-4 ply pod base to

bottom of fuse sheeting w i t h front edge

securely against F-4. Glue forward pod

former P-2 carefully to P-4 (Keep glue off

of F-4 and be sure to center P-2). Glue

triangular 1/4" stock to bottoms of P-1 pod

sides - be sure you make a LEFT and RIGHT

pod side!

18. As shown on the plans the pod is held in

place at the front with two 5/8" lengths

of 1/16" music wire. The two required

holes for their locating/mounting pins must

now be drilled through P-2 and F-4. D r i l l

1/16" holes. Insert the two 1/16" x 1-1/2"

music wire pins in place and glue securely

to the P-4 pod base and P-2 former.

19. Now glue the P-1 pod sides in place to P-

2/P-4 making sure the P-1's match the

fuselage sides. Make certain to keep glue

off of fuse sides. See drawing below.

20. Glue 1/8" x 3/8" spruce/ply to bottom of

P-4 and butt up to P-3.

21. Fit and glue P-6 and pod tail blocks in

place. D r i l l cooling air outlet holes and

sand bottom of pod to accept P-5.

22. Now drill and tap pod screw plate with an

8-32 tap. Glue P-5 in place. Locate the

1/2"x 2" x 12" length of balsa. Using a

sanding block, bevel-sand one end of the

block to f i t against the forward face of

F-4, holding it in place at the top of the

fuselage.

23. The forward end of the radio hatch is now

cut at the angle shown on the plans. Once

the bevel cut has been made, use the

sanding block to l i g h t l y clean up each end

of the cut. Set aside the hatch part for

a moment. On the remaining length of block

measure forward from the bevel cut and cut

this piece off. This then becomes the

forward "lip" for the radio hatch. Use

tape to hold the radio hatch in place to

the top of the fuselage, against F-4.

Apply a small amount of glue to the bottom

of the forward block and glue i t in place

to the top of the fuselage and nose block,

matching the bevel on the front of the

radio hatch block, thus insuring a nice f i t

between these two blocks. Untape and

remove the radio hatch block. Locate and

remove the ply hatch "lip" from i t s die-cut

sheet. F-4 can now be glued to the

forward, bottom surface of the hatch block

with 3/16" of its forward end protruding,

thus providing a f i t beneath the forward

block just installed and preventing

shifting from side-to-side. Install the

two 1/8" square hatch locators. Repeat

procedure for the bottom nose block. The

bottom block, not being removable, can now

be glued in place.

24. The next step is to assemble the nose

block. Glue the plywood spinner ring to

the 1/4"x 1-3/4" x 2" balsa nose block,

carefully centering i t . After the block

has dried, remove center section by cutting

along center of spinner ring with a #11

blade. Sand the front of the fuselage per

section B-B to accept the nose block

assembly. A l i g n the nose block w i t h the

motor shaft and cement to F-3. The cool-

air intake hole can be d r i l l e d at this time

(see photo below).

10