Top Flite Holy Smoke User Manual

Page 6

the cable/tube assembly around to the exit point

shown at the aileron horn location. Use a marking

pen to note the location of the tube on each rib.

Repeat this operation for the opposite wing panel.

Again, use the 1/8" drill bit to drill holes through the

W-2's and W-3's that will allow the tubing to pass.

Now use a piece of sharpened 1/8" dia. tubing to

make the tubing exits, at the angles shown, through

the bottom, rear planking. With the cables still in-

side the tubes, feed the tubes through the various

holes until they exit. Test the action of the cables;

movement should be free and easy. Once satisfied,

use slow setting CA to anchor the tubes in place to

the ribs and planking. Trim the aileron exit tube ends

flush with the planking—remove the cables and set

aside for installation when the airplane is finished.

24. You should have about 15"-16" of white tubing left

over from the antenna tube; this will be used for the

nosegear steering cable. As shown, this cable is

driven by the opposite end of your servo's output

arm. Locate the remaining 12" length of braided

cable and solder the brass coupler in place. Thread

one of the black nylon mini-links in place on the

coupler. This will be the servo end of the steering

cable. From your planking stock (3/32" balsa), cut a

2-7/16" x 3-7/8" rectangle and glue this in place on the

W-1 ribs and flush with the front face of W-9. You

should wind-up with a little of the W-1's thicknes still

exposed on each side to allow seating for the rest of

the bottom planking—fit this piece carefully. As

before with the aileron tubes, drill a 1/8" dia. hole

through the right-side W-1 at the correct position for

the servo's output arm to drive the steering cable.

Slip the cable into the tubing and hold it in position

over this hole, again, you might have a friend hold it

there for you. Now gently bend the cable/tubing as

shown on the plans around towards the nose to the

exit point shown. Use a marker to note the passage

point through W-1 at the front. Use a drill bit to drill

the hole through W-1 and a sharpened piece of tub-

ing to make the exit hole through the planking just in-

stalled. Install the tubing through all three holes and

test the action of the cable, as before, it should be a

free fit. Adjust the tubing to obtain the optimum

movement and glue it in place. Remove the cable

and the aileron servo. Trim the tubing flush with the

planking.

25. The balance of the bottom planking can now be in-

stalled. In order to find and clear out the landing gear

skid slots later, use a straight edge and pencil to

make horizontal and vertical reference marks on the

sheeting already in place. Note that the hatch area is

left open with the inboard ends of the planking trim-

med flush with the inboard faces of the W-1's. All

that should remain after planking is the open hatch

area and the nose bottom.

26. From the kit, locate the four blocks required to fill-in

the bottom nose area; 2 @ 1" x 1-1/2" x 5-1/2" balsa; 1

@ 3/4" x 1" x 3-1/2 " balsa and 1 @ 3/4" x 1-7/8" x 2"

bssswood. The hardwood block is used to mount the

5/32" dia. coiled nose gear. The two 1-1/2" wide balsa

blocks fit on the outside edges of the W-1 's, against

the W-7 ply floor and against the face of W-9. The re-

maining 3/4" wide block fills in the remaining slot.

Use your sanding block as needed to achieve a good,

flush fit of these four blocks. Use a drill press to drill

a vertical 5/32" dia. hole through the hardwood block

at the position shown on the plans for the nose gear.

Glue all four blocks in place. After the glue has set,

chuck-up the 5/32" dia. drill bit in a hand drill and com-

plete the hole in the hardwood block all the way

through the floor, into the engine compartment.

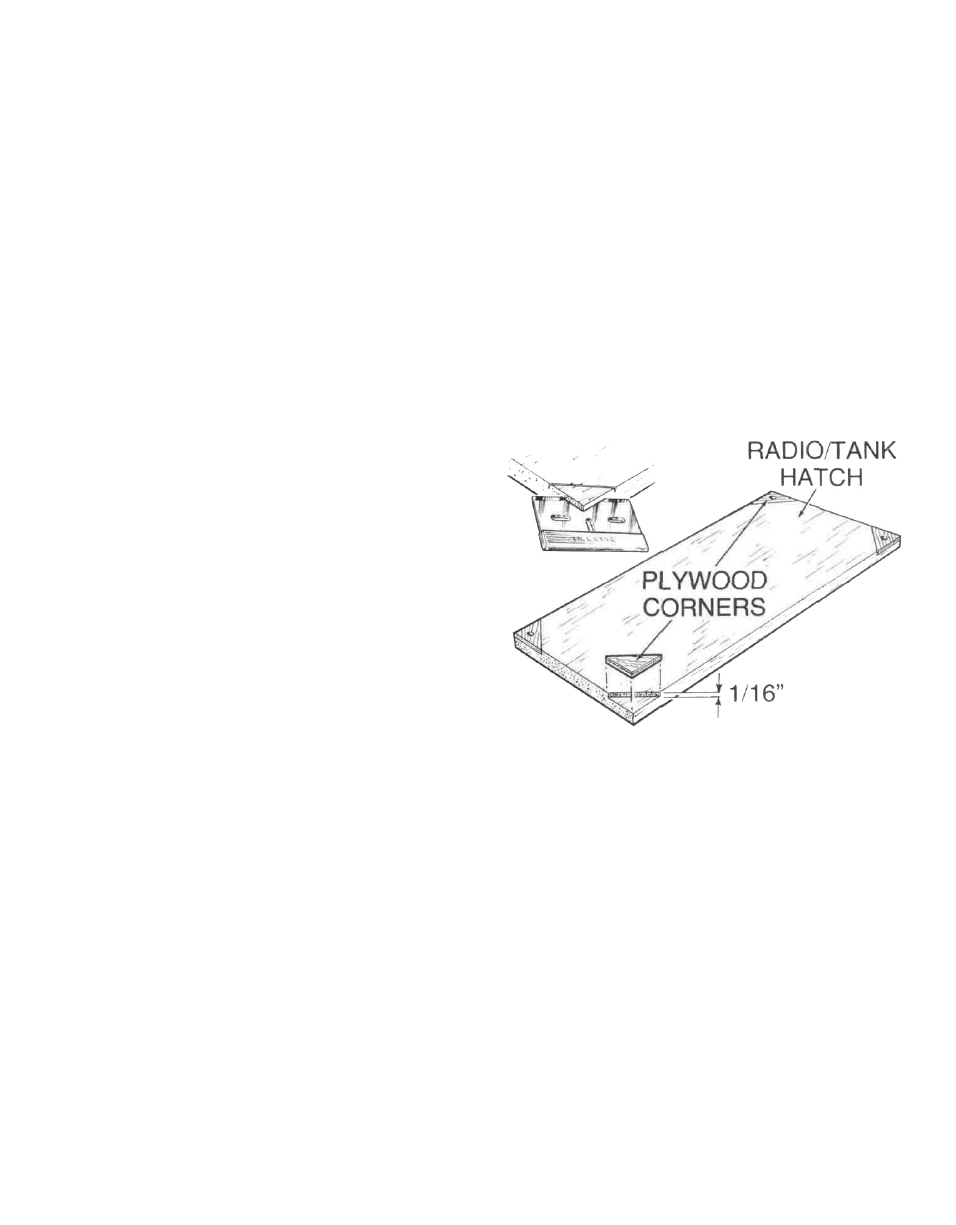

27. The radio compartment hatch supplied in your kit

measures 1/4" x 3 - 3 / 4 " x 9" and is balsa. It is mounted

to the four 1/2" sq. hardwood blocks supplied. Glue

these blocks in place in the four corners of the hatch

opening at a depth which will leave the hatch flush

with the planking. Install the four die-cut ply

triangles that were left from die-cut sheet RC-34-6,

on each corner of the hatch. Use a razor blade to

remove 1/16" of depth of the hatch corners, in the

shape of the ply triangles and epoxy these in place.

Now locate the hatch in position on the four hard-

wood mounts—use tape to hold it there if need be.

With a 3/32" drill bit, drill a guide hole through each of

the four corners of the hatch and in contact with the

hardwood mounts, just enough to leave a mark on

each of the mounts. Remove the hatch and use a 1/16"

drill bit to drill a guide hole through each of the

mounts. Locate four of the #2 x 3/8" wood screws sup-

plied and screw the hatch in place to the mounts.

Once satisfied with the fit, remove the screws and

lightly tack glue the hatch in place to the

mounts—you want to be able to remove it after san-

ding. Using the cross-reference marks made earlier,

use an X-acto knife to clear-out the two rear landing

skid slots.

28. Use a razor blade to first rough shape the upper and

lower nose blocks. Follow this with a sanding block

and coarse sandpaper to bring these blocks down

further. Use the razor plane again to rough shape the

leading edges—refer to cross-sections on the plans.

Finally, the entire wing can be sanded with pro-

gressively lighter sandpaper until ready for cover-

ing. Take your time and get it right. Remove the tack

glued hatch and set it aside for covering.

6