Top Flite Holy Smoke User Manual

Page 4

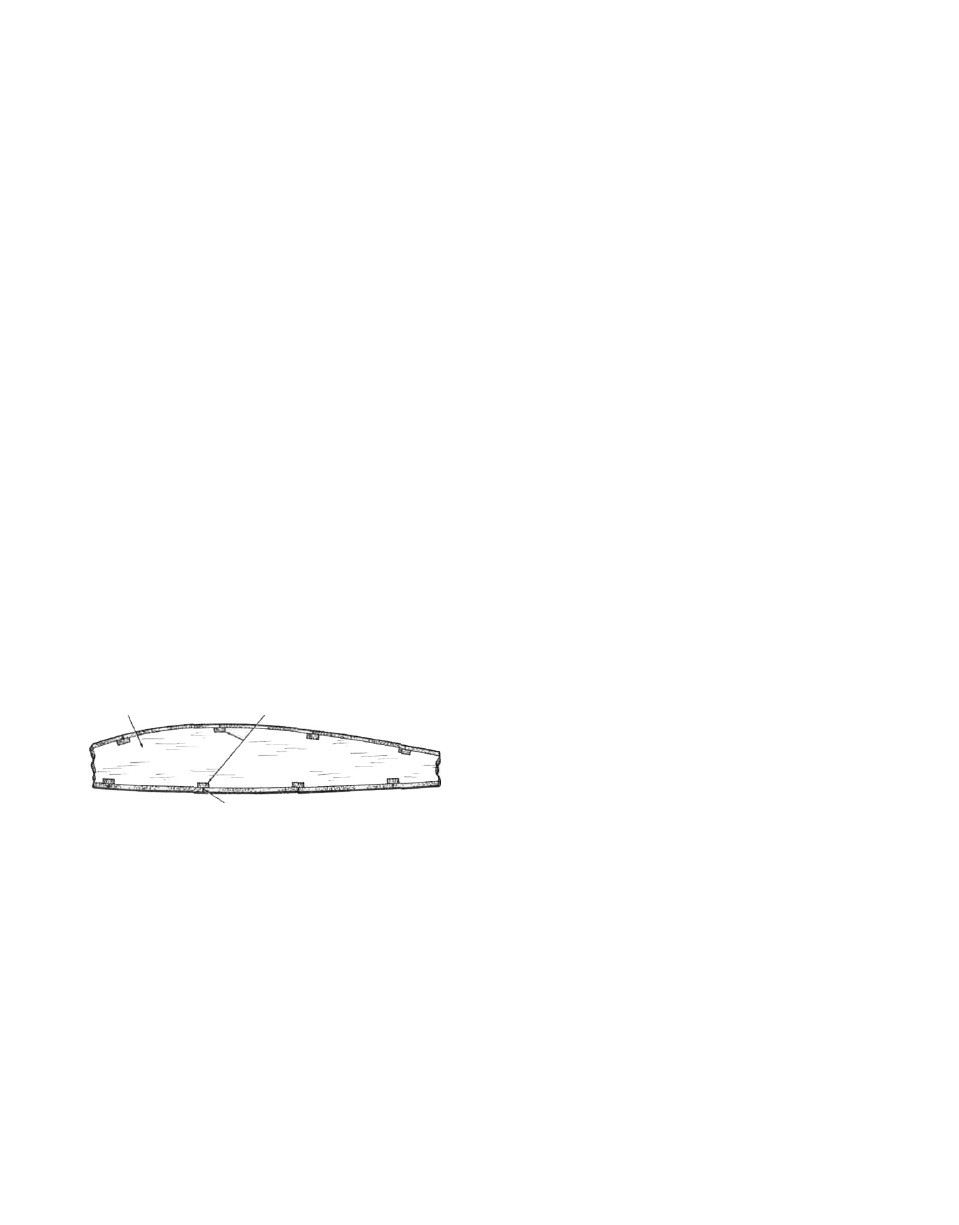

7. The first piece of planking that you are going to at-

tach will be the rear one which is one-piece from tip

to tip and flush with the bottom 3/32" x 7/8" balsa strip

installed in the rib slots earlier—see cross-sections

on plans. Glue and pin this rear piece of planking in

place to the tops of the ribs and along the trailing

edge of the bottom sheet.

8. The next two pieces of planking to be installed are

those that fit from the the centerline of the spars, for-

ward to the rear face of the landing edges. Trim the

inboard ends to fit flush with the inside faces of the

W-1 ribs and on top of W-9, as shown. Once the plank-

ing pieces are trimmed to fit, use a little ammonia on

their top surfaces to get them to bend easier to fit the

tops of the ribs. Glue these two pieces of planking in

place, pin or weight as needed and allow to dry.

9. Remove W-10 from its die-cut sheet and lightly sand

its edges to fit between the W-1 's at the rear position

shown on the plans. Use a triangle to accurately

locate this former and glue it in place, aligning the

top edge with the tops of the W-1's.

10. Using the left-hand view of the wing (remember,

that's the top planking patterns shown), finish plank-

ing the left and right-hand side of the top of the wing.

Trim the centerline ends of each piece of planking to

provide a true centerline for accurately locating the

fin. Note that the entire left and right center planking

pieces can also be made separately, on a flat sur-

face and then fitted in place on each side of the

centerline. Just be sure that, if you do it this way, you

leave just a little extra material at the rear to trim and

therefore achieve a nice, gapless fit.

SCRAP 3/32" BALSA STRIPS IN

PLACE BETWEEN RIBS AS "SHELVES"

RIB (TYPICAL) FOR BUTT-SHEETING

SHEETING JOINT

11. Using the 1/4"x3"x36" piece of balsa provided and

the pattern shown on the plans, carefully cut and

glue the four required pieces together to form the

rough shape of the fin. Use a sanding block to finish

the fin into the side-view configuration shown.

Follow this by sanding the fin assembly smooth on

each side and then rounding the leading, trailing and

top edges to a "half-round", as shown. Streamlining

or airfoiling this surface is not needed or desirable.

12. The fin's support tab requires a slot that is 1/4" wide

and 3-1/16" long. This is located on the exact

centerline of the wing. As shown on the plans, the

rear end of this slot is measured at 3-1/16" from the

trailing edge. Cut this slot with a fresh #11 X-acto

blade. The forward end of the slot should be at the

rear face of W-10. Trial fit the fin in place and dress

the bottom edge of it as required to achieve a

uniform fit to the top surface of the wing's planking.

Once satisfied, set aside the fin for later installation.

13. From your parts bag, locate the four 4-40 blind moun-

ting nuts and their corresponding 1-1/4" motor mount

bolts. Also locate the two 3/16" x 3/4" x 5-1/2" maple

motor mounts and the two top 7/8" x 1-3/4" x 5-1/2"

balsa cowl blocks. Before assemblying the motor

mounts and cowl blocks in place as shown on the

plans, let's first trial fit the whole thing on the nose

with your engine sitting in place between the maple

mounts. Is the fit a comfortable one or is it too tight

or too loose? Engines vary somewhat in case width

and if yours happens to be a little too wide, then you

will find that the engine will either not fit at all or a lit-

tle too tight. If this is the case then you must use a

sanding block to remove a little of the width from the

two balsa cowl blocks. Try to do this evenly and a lit-

tle at a time while continually trial-fitting the engine.

Once satisfied, you can move on to the next step. If

your engine fits too loosely between the mounts

then you must add material to the sides of the cowl

blocks to space them out a little. 1/16" sheet balsa on

each block would move the mounts inward 1/8", etc.

14. Glue the balsa cowl blocks in place in the nose

against the inside faces of the W-1's, against the

front face of W-9 and against the W-7 ply floor. Use a

scrap of balsa to scrape out any oozing glue

because we want the maple motor mounts to fit in

place squarely to the floor and the cowl blocks.

Lightly tack glue the two maple motor mounts to the

ply floor only, exactly in the position they will even-

tually be. Set your engine in place on the mounts

with the thrust washer just clearing the front of the

nose (see top view and engine cross-section on

plans). Now carefully mark the lug hole positions on

the motor mounts with a pencil or sharpened object

of some kind. Remove the engine and break the two

motor mounts free from the ply floor. Use a drill

press and a 1/8" dia. drill bit to drill the two required

holes in each motor mount (a hand drill can be used

if you are careful). In order to get the motor mounts to

sit flush against the W-7 ply floor, you must now use

a Moto-Tool and grinder bit to counter-sink the 4-40

blind nuts. Epoxy these nuts in place to the bottom

of each motor mount, being careful to keep glue out

of the nut's threads. Using medium to slow curing

epoxy, glue the mounts permanently in place. When

the glue has cured remove the pins holding the struc-

ture in place to your building board and remove the

wing.

15. Turn the wing over exposing the unplanked bottom

and block-up the nose until the trailing edge lays flat

to your work surface. Use an X-acto knife to carefully

remove the rear building tabs on all of the ribs. This

exposes the forward edge of the bottom trailing

edge strip installed at the beginning. Take one of the

3/32" x 3 " x 36" planking pieces, true-up its edges with

a straight-edge and razor and glue it in place against

the forward edge of the trailing edge piece and

against each rib. (We found that a truer butt-joint

could be made by first gluing scrap pieces of balsa

underneath the piece of balsa planking that was

already in place thus creating a sort of "shelf". The

excess material left over from the die-cut sheets pro-

vides plenty of these shelf pieces.) Pin or weight this

4