Top Flite Holy Smoke User Manual

Page 3

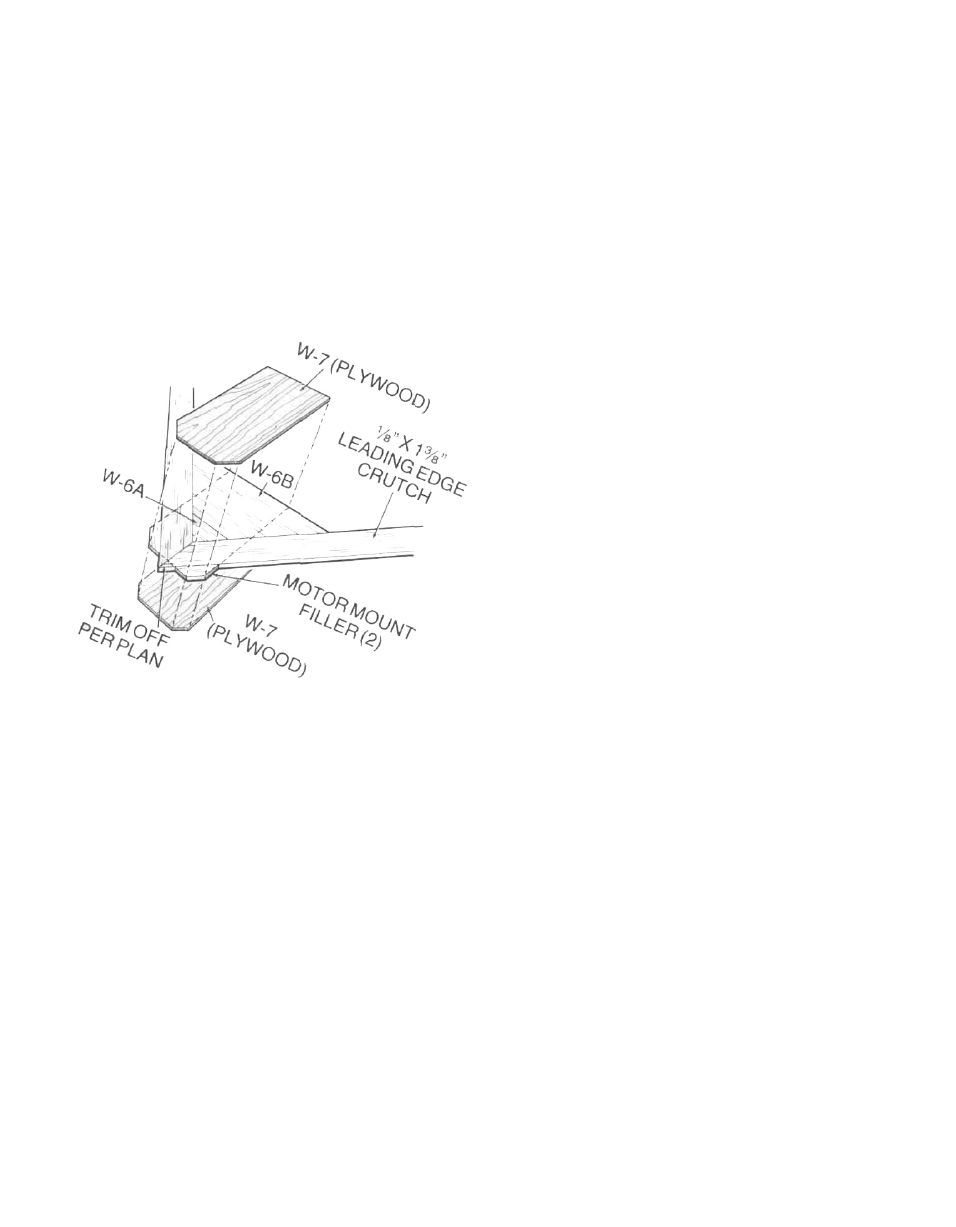

3. Locate die-cut sheet RC-34-1 (2 req'd.) and remove

the two Motor Mount Fillers. These are now glued in

place against the leading edges of the two leading

edge crutches, at the nose, directly behind the spin-

ner shown on the plans. Now use your sanding block

to lightly smooth off the glue joints. From the ply die-

cut sheet RC-34-6, remove the two W-7 parts. Use

your sanding block to clean up their edges. Glue one

of the W-7 parts directly on top of the leading edge

crutch assembly, aligning its rear edge with the rear

edge of W-6B and its forward edges with those of the

two motor mount fillers. Use weights to make sure

that W-7 stays flat against the leading edge crutch

assembly until it is dry.

4. Remove the leading edge crutch from the plans, turn

it over and use your sanding block to smooth out any

glue joints. Glue the remaining W-7 part in place to

the bottom surface of the crutch assembly, exactly

aligned with the W-7 previously glued to the top sur-

face. Again, use weights to hold this part in place

and allow it to dry.

Remove this assembly from your building board as

we will now build the rest of the airplane.

GENERAL CONSTRUCTION

1. From the die-cut sheets provided, carefully remove

all of the required wing ribs W-1 through W-5, two of

each. Note that these ribs each have temporary

"tabs" attached to the front and rear ends (W-2 and

W-3 have them in the center as well). These are there

to provide stability during construction on a flat sur-

face—do not remove these until told to do so. Use

pins to now locate each rib in its appropriate posi-

tion over the plans and vertical to your work surface.

We would suggest using a 90° triangle to be sure

that the ribs are truly vertical.

2. Carefully slide the previously built leading edge

crutch assembly into the slots provided on the front

of each rib (except W-5). The ply W-7's should fit on

the inside faces of the two W-1 's at the nose and the

outer ends of the crutch assembly should be in con-

tact with the inner surfaces of the two W-5's. It may

be necessary to trim a little here or there to achieve

the proper fit. If so, do it now.

With the crutch still in place but not yet glued, turn

your attention to the slots provided in the ends of

each rib. Locate the 3/32" x 7/8" x 36" bottom trailing

edge balsa piece provided in your kit and carefully

slide it into place in the rear rib slots.

Now take the time to inspect this structure for cor-

rect alignment and that each piece is indeed contac-

ting the other in the previously described manner.

Once satisfied, glue the leading edge crutch and

trailing edge piece to each rib. A slow-setting CA is

just the ticket here. Don't worry about getting glue

onto the bottom of the crutch assembly, we'll do that

when we remove the structure from the building

board.

3. From die-cut sheet RC-34-2, carefully remove former

W-9. Lightly sand the edges of this part to fit in place

between the two W-1 ribs and against the rear edge

of the crutch assembly. Note that the "peaked" side

of W-9 is the top. Once satisfied, glue W-9 in place,

again being sure that it is vertical to your building

surface.

4.There are four(4) 3/16"x3/8"x24" wing spars provided

in your kit; locate two of them. Bevel the inboard

ends of these spars to fit against W-9 as shown on

the plans. Test fit the spars in place in the slots pro-

vided. Once satisfied, glue these spars in place. Trim

the outer ends flush with the outer faces of the two

W-5's.

5. Use light sandpaper and your sanding block to now

bevel the front edges of each rib flush with the

leading edge crutch. From your kit box remove the

two 1/2" x 1-1/8" x 36" balsa strips provided. These are

the leading edges and wingtip material. From each

piece cut a 24" length and place the balance back in

the kit box for later use. Bevel the inner and outer

ends of the two 24" pieces to fit in place as shown on

the plans. Note that each rib has been provided with

"lip" at the leading edge; these position the leading

edge accurately for gluing. Glue the leading edges in

place to each rib and the front edge of the crutch

assembly. Pin and/or weight as needed and allow to

dry.

6. Your kit has been provided with twelve pieces of 3/32"

x 3" x 36" balsa for planking purposes, locate and

have ready six of these at this time. Stress-relieved

balsa sheet can sometimes have curved edges and it

may be necessary for you to use a straight-edge and

X-acto knife to true them up. This is important

especially when the wood is used for butt-glued

planking purposes.

IMPORTANT NOTE: The plans depict the top view of

the airplane. The right side is shown with the top

planking removed and you can therefore see the

planking patterns used for the bottom of the wing.

The left side of the wing depicts the patterns used

for the top sheeting. In the next steps we are dealing

only with the top sheeting.

3