Top Flite Elder 40 User Manual

Page 9

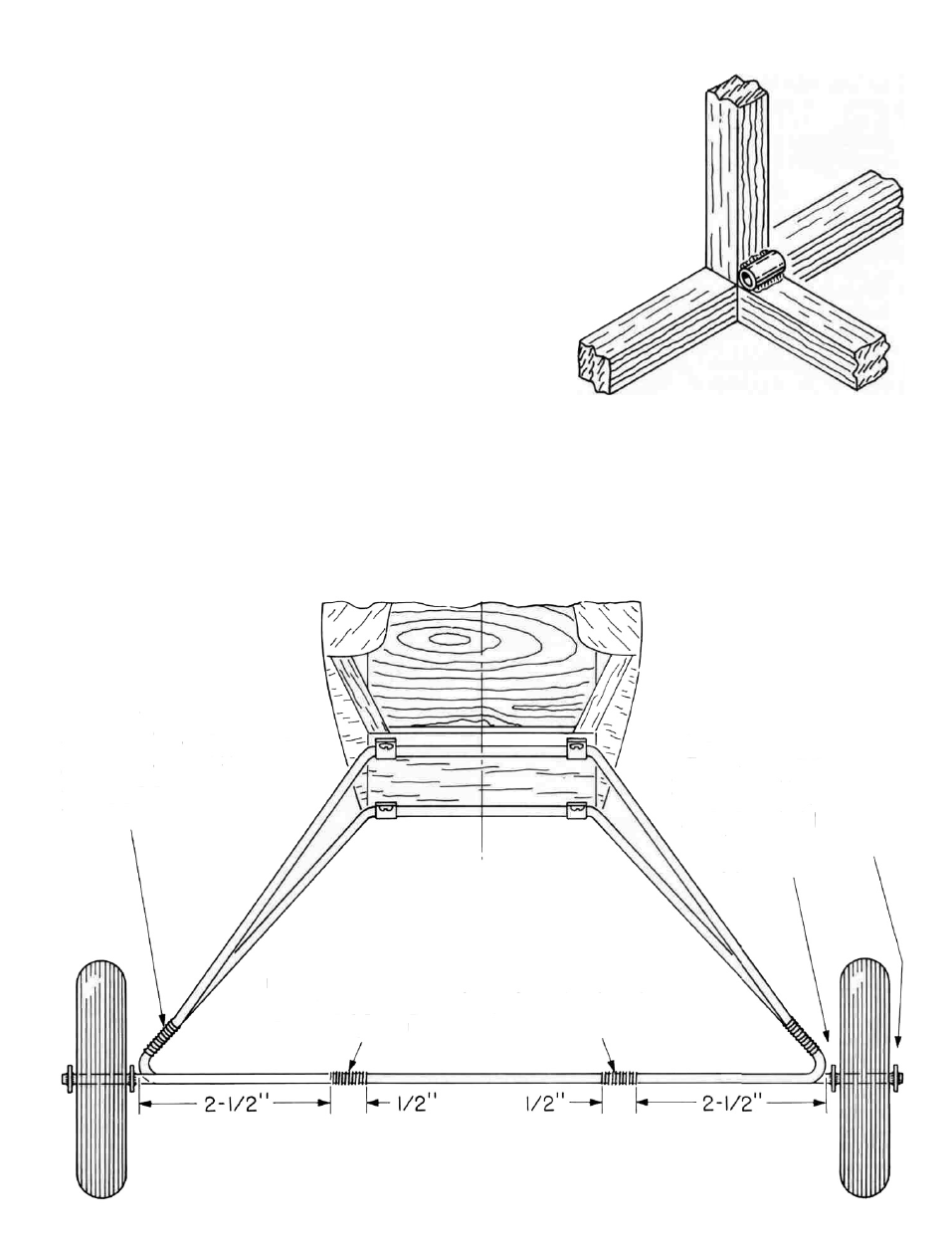

OPTIONAL DECORATION DETAIL-

1/4" LENGTHS OF 3/32" OR 1/8" DIA. PLASTIC

TUBING CAN BE EPOXIED INTO EACH JOINT

BETWEEN A SPRUCE CROSS BRACE AND

UPRIGHT (16 PLACES). LATER,"RIGGING" IS

THREADED THROUGH EACH TUBE, DRAWN

TIGHT AND EPOXIED IN PLACE.

arms to the rear L/G wire as shown on the plans. App-

ly some STAY-CLEAN flux to the joint and solder.

Repeat the process on the other side. Be neat and try

to be sure that the joint is solid without a lot of ex-

cess solder. Once satisfied, completely clean the

solder joints of any flux.

4. As shown, the crossed-axle landing gear system

derives its ability to accept landing loads and shock

from the two (2) independent axle legs. These need

to be joined at two points, each 2-1/2" in from the

wheels. This distance has shown very good shock-

absorbing ability for Elder's weighing 4 to 6 lbs. Join

these axles by first measuring the 2-1/2" distance re-

quired, wrapping with soft wire (about 1/2" ) and

soldering. Again, clean the solder joints completely.

FRONT AND REAR

STRUTS ARE BOUND

TOGETHER WITH FINE

COPPER W I R E , T H E N

SOLDERED

THOROUGHLY.

9

FOR PERMANENCE.

RETAIN WHEELS ON

AXLE WITH WASHERS.

SOLDERED IN PLACE.

ALTERNATE METHOD

IS TO USE WHEEL

COLLARS.*

BIND AXLE SECTIONS OF LANDING

GEAR TOGETHER WITH THIN COPPER W I R E ,

THEN SOLDER PER DIMENSIONS SHOWN.