Top Flite TOPA0955 User Manual

Page 18

18

of the engine on the mount . The Great Planes

®

“Dead

Center” Hole Locator (GPMR8130) works well for

this . Drill through the marks you have made with a

#29 or 9/64" [3 .6mm] drill bit . Tap each hole with an

8-32 tap .

o

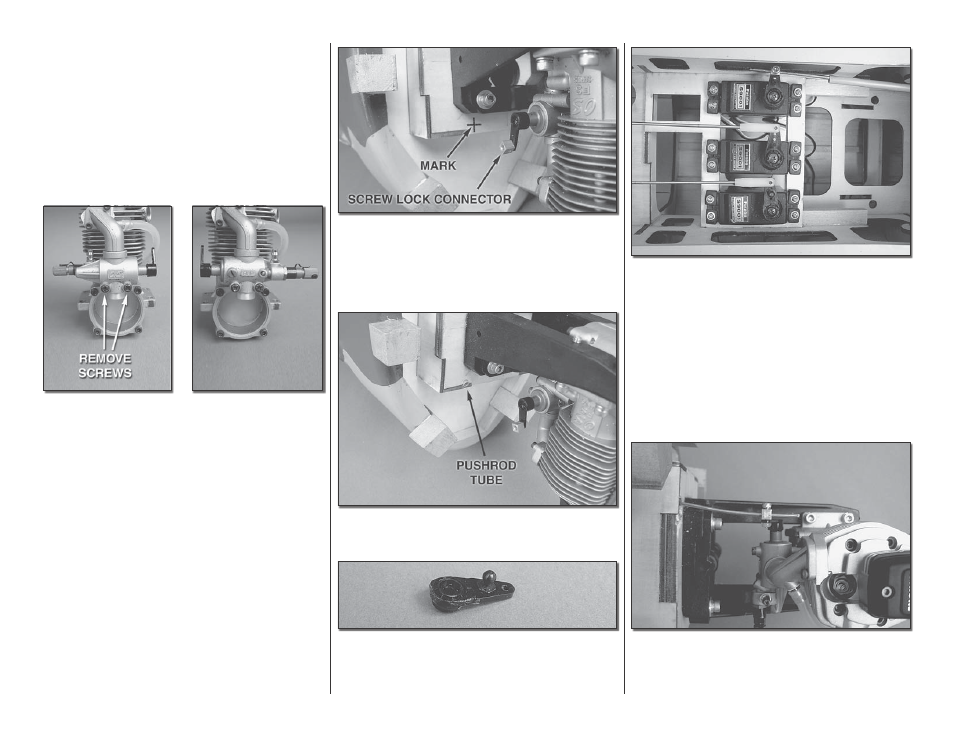

4 . Before installing the engine to the mount, check

the location of the throttle arm . Looking from the back

of the engine, the arm needs to be on the left side .

The O .S . engines allow you to rotate the carburetor .

Remove the two screws holding the carburetor to the

engine . Remove the carburetor, rotate it 180 degrees,

and then re-install the screws . Engines other than O .S .

may or may not allow you to rotate the carburetor . If

you cannot, you will have to position the throttle servo

in a different location than you will be instructed later

in this manual .

o

5 . Install the engine to the mount with four each,

8-32 x 1" [25mm] socket head cap screws, #8 lock

washers and #8 flat washers .

o

6 . Install a brass screw lock connector to the outer

hole of the throttle arm . Lock it to the arm with a nylon

retainer . Slide a pushrod wire through the connector,

touching it to the firewall . Make a mark where the wire

will pass through the firewall .

o

7 . Drill a 3/16" [4 .8mm] hole on the mark . Glue a

12" [305mm] plastic tube into the hole .

o

8 . Remove the servo arm from the rudder . Install

a ball link into the second hole from the center . Lock

it to the servo horn with the 0-80 nut . Re-install the

horn to the servo .

o

9 . Slide the wire from the throttle into the brass

screw lock connector . Lock the wire to the connector

with a 4-40 x 1/8" [3mm] socket head cap screw . For

the rudder and elevator, center the control surfaces .

Make a mark on the pushrod where it crosses the

outer hole in the servo arm . Make a 90 degree bend

at the mark on the pushrod and cut off the excess

pushrod 1/4" [6mm] beyond the bend . Attach the

pushrod to the servo arm using a nylon FasLink .

Make sure all of the servo horn screws are installed

in the servos .

o

10 . Bend the throttle pushrod slightly to get a

smooth movement of the pushrod wire and then

secure the wire with a 4-40 x 1/8" [3mm] socket head

cap screw . Be sure to apply threadlocker to the bolt .

Remove screws to

rotate carburetor

Correct position

for throttle arm